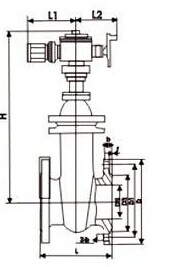

DN125 Ductile Iron Rubber Gate Valve with non-rising stem

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Soft seal gate valve

Size:DN40mm-600mm

Design standard: DIN 3352/BS 5163/AWWA C509/JIS B2043

Test standard: DIN3230/BS 6755/AWWA C509/JIS B2003

End flange standard: DIN 2533 PN16/BS 4504 PN16/ANSI 150LB/JIS B2212 10K

Face to face standard: DIN 3202 F4/DIN 3202 F5/BS 5163/ANSI 16.10/JIS B2002

Body: Ductile iron/GGG50/A536

Wedge: Ductile iron+EPDM/Ductile iron+NBR

Stem: Brass/SS416/2Cr13

Bonnet: Ductile iron/GGG50

Handwheel: Ductile iron/GGG50

The products are widely used in water source projects, urban water supply and drainage, sewage treatment, eletric power, petroleum, petrochemical, heat supply, shipbuilding, medicine and metallurgy industries. Equipment are used for regulating or cutting off media in pipelines. Suitable media include water sewage, sea water, air, foodstuff and oil. Suitable for gear operators, electric and pneumatic control actuators.

- Q: What are the working principles of the electric gate valve?

- We see you what type of electric valve, is integral or ordinary type, if the overall type Denso took power on the line, is generally 380V and 220V power supply, and then according to their own needs and then open the signal line, in place and closing in place and remote control line, valve position feedback signal the commonly used 4~20ma over torque protection fault signal.

- Q: What gate DH10016, AM

- The first Z represents the gate valve (the initial consonant of the Chinese phonetic alphabet for the gate); the second 2 represents the drive mode of the valve, that is, electro hydraulic drive.

- Q: What does gate valve Z41H-40 mean?

- Z - that means gate valve (the initial letter of Zha)4---- is the connection form, which means flange connection1---- form of structure, which means Plain Bar wedge type rigid single gate valveH---- sealing surface overlaying ferrous carbide (initial letter of alloy steel He)40---- nominal pressure is 40 kg, or 4.0MPa, that is, PN10 at 250 degrees Celsius, the maximum working pressure is 40 kgThe material is cast carbon steel

- Q: What is the standard length of GB steel gate valve?

- 1, product standardsGeneral purpose valves, flanged connections, iron gate valves, GB/T 12232-2005General requirements for steel valves GB/T 12224-2005"Steel flat gate valves for pipelines" JB/T 5298-91Inspection and test of valves. JB/T 9092-1999Standard for safety evaluation of drinking water distribution equipment and protective materials GB/T 17219-1998

- Q: Soft sealed gate valve and hard sealing gate valve which good?

- If the caliber, material and pressure levels are the same, the current market price is still soft sealed gate valve, about 20-30%.

- Q: What are the features and uses of the gate valve?

- What is gate valve? What is the purpose of forged steel gate valves? What are the features of forged steel gate valves?Is the gate valve opening and closing parts, RAM direction of motion perpendicular to the direction of the fluid, valve can only be fully open and fully closed, can not be adjusted and the throttle. The gate valve movement direction perpendicular to the direction of the fluid, valve can only be fully open and fully closed, can not be adjusted and the throttle. The gate has two sealing surfaces, and the two sealing surfaces of the most commonly used gate valves form wedge and wedge angles vary with valve parameters. Gate valve drive classification: manual gate valve, pneumatic gate valve, electric gate valve.DefinitionGate valve means the closing of the valve (gate) along the central line of the vertical direction of the valve. The gate valve is mainly used for cutting in the pipeline.The valve is a valve with a very wide, cutting device general caliber DN = 50mm use it, sometimes a small diameter cutting device also use valve, gate valve has the following advantages:Fluid resistance is small.Minor force needed for opening and closing.Medium flow is unrestricted.When opening fully, the sealing surface is eroded by the working medium smaller than the cut-off valve.The shape is relatively simple and the casting process is betterValve also has shortcomings:The overall size and opening height are larger. Larger space required for installation.In the process of opening and closing, there is relative friction between the sealing surfaces, which may cause galling.Gate valve generally has two sealing surface, processing, grinding and maintenance to increase some difficulties.

- Q: Gate valve type Z40Y, Z40H letters - what does that mean?

- According to the provisions of the JB/T 308-2004 valve type programming method:Z== gate valve4== connection: flange0== structure: wedge type elastic RAMY== sealing surface material: hard alloyH== sealing surface material: Cr13 stainless steel

- Q: What does gate z41t-10 150 mean?

- According to JB/T308-2004 "valve type programming method"Z gate valve4 flange connection1 Ming wedge single gateT sealing cover material is copper alloy10 nominal pressure PN10PN16 below no marked valve body code, body material is gray cast iron150 nominal size DN150

- Q: What are the structural differences between parallel and wedge valves?

- The structure of globe valve and gate valve. What does this article introduce first?What is parallel gate valve?The sealing cover is parallel to the vertical center line, so the sealing surfaces of the valve body and the gate are parallel to each other. This gate valve is the most common double gate plate, in order to shut down, so that the valve and gate two sealing surface contact closely asked, often used in two ram double sided thrust wedge block. Thus, when the valve is closed, the double side thrust block is contacted with the bottom of the valve body and is gradually stressed.

- Q: What is the gate valve for the DN65 hydrant?

- Fire hydrant with 65 butterfly valve, ah, how do you use the gate valve?

Send your message to us

DN125 Ductile Iron Rubber Gate Valve with non-rising stem

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords