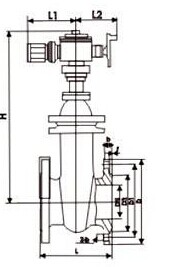

DN65 Ductile Iron Rubber Gate Valve With Long Stem

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Soft seal gate valve

Size:DN40mm-600mm

Design standard: DIN 3352/BS 5163/AWWA C509/JIS B2043

Test standard: DIN3230/BS 6755/AWWA C509/JIS B2003

End flange standard: DIN 2533 PN16/BS 4504 PN16/ANSI 150LB/JIS B2212 10K

Face to face standard: DIN 3202 F4/DIN 3202 F5/BS 5163/ANSI 16.10/JIS B2002

Body: Ductile iron/GGG50/A536

Wedge: Ductile iron+EPDM/Ductile iron+NBR

Stem: Brass/SS416/2Cr13

Bonnet: Ductile iron/GGG50

Handwheel: Ductile iron/GGG50

The products are widely used in water source projects, urban water supply and drainage, sewage treatment, eletric power, petroleum, petrochemical, heat supply, shipbuilding, medicine and metallurgy industries. Equipment are used for regulating or cutting off media in pipelines. Suitable media include water sewage, sea water, air, foodstuff and oil. Suitable for gear operators, electric and pneumatic control actuators.

- Q: What is the difference between the copper gate valve and the ordinary material gate valve?!

- The copper gate valve is made of copper alloy, and the common materials are made of stainless steel, cast steel, cast iron, and so on. Now there are new types of ceramic gate valves. Different properties of the gate valve performance, processing technology, service life, applicable occasions are a certain difference. Copper gate valves should be used for fire end water outlet installations as well as other occasions with special requirements.

- Q: What are the working principles of the electric gate valve?

- We see you what type of electric valve, is integral or ordinary type, if the overall type Denso took power on the line, is generally 380V and 220V power supply, and then according to their own needs and then open the signal line, in place and closing in place and remote control line, valve position feedback signal the commonly used 4~20ma over torque protection fault signal.

- Q: What are the specifications of the gate valves? Does the work pressure need to be marked separately?

- According to domestic valve model standards, the valve model is by the valve type, gate valve drive mode, gate valve connection, gate valve structure, sealing material, valve body material code to indicate.1, gate valve type code named Z;2, gate valve drive mode code by letters, common 2- electric hydraulic, 9- electric, 6- pneumatic, 5- bevel gear drive, 3- turbo worm; manual do not need to write out;3, gate valve connection form code with letters to indicate, 1- internal thread, 2- external thread, 4- flange type, 6- welding, 7- pairs clamp type, 9- clamp, 0- card sleeve;4, the valve structure of code, 0- flexible wedge, 1- rod single wedge gate valve, 2- rising stem wedge gate valve, 3- parallel single gate valve, 4- parallel double gate valve,

- Q: Valve flange drawing n- up to what

- A bolt hole used to indicate a flangeThe value of N indicates the number of bolt holesUp to the numerical representation of bolt hole size

- Q: Why is gate valve or butterfly valve used for water pump?

- General pressure is small, use the butterfly valve, when the pressure is big, use the gate valve. The two main function of the valve is to adjust the flow and easy to overhaul.Zibo Boshan new Duke water supply equipment

- Q: Z45T-10 what kind of material is the gate valve?

- Z45T-10 refers to the nominal pressure of 1Mpa gray iron valve. The meaning of letters and numbers is:(Z) - gate valve;(4) indication - internal thread connection;(5) indicating dark wedge rigid single gate;(T) - the body is made of copper or copper alloy;(10) indication nominal pressure 1 mpa.Is the gate valve opening and closing parts, RAM direction of motion perpendicular to the direction of the fluid, valve can only be fully open and fully closed, can not be adjusted and the throttle. The gate has two sealing surfaces, and the two sealing surfaces of the most commonly used gate valves form wedge and wedge angle valves.

- Q: What kind of gate valve is Z6CS-H102?

- Z== valve type: gate valve6== pressure rating: 800LB, API602C== structure: bolt connection, valve cover, bolt connection gland, bright rod support typeS== connection form: socket welding, that is, SWH1== body material: A10502== inner material: seat sealing surface STL, gate sealing surface STL, valve stem 13Cr

- Q: What are the common standards for gate valves?

- Is the gate valve opening and closing parts, RAM direction of motion perpendicular to the direction of the fluid, valve can only be fully open and fully closed, can not be adjusted and the throttle. The following common standards for Fujian Biaoguang valve for valve: design specification: JB/T 7746, API602 JB/T 7746, the length of the structure specification / thread socket factory test and inspection of JB/T1751/GB7306, ANSI: B16.11/B2.1: JB/T 9092, API598 pressure temperature: GB/T 9131, ANSI B16.34, MSS GB/T 12220 product ID: SP25 delivery specification: JB/T 7928

- Q: What do gates, Z15T-10, Z15W-16T, Z45T/W-10, Z41T-10 mean?

- Z15T stands for manual, internal thread connection, dark wedge single gate. The sealing surface is made of copper alloy. The nominal pressure is PN1MPa;Z15W-16T for manual, internal thread connection, dark wedge type single gate, the valve body material is copper alloy, the valve seat sealing surface material directly processed by the valve body, nominal pressure is PN1.6MPa;Z45T/W-10 stands for manual, flange connection, dark wedge single gate. The valve body is made of copper alloy, and the valve seat face material is directly machined by the valve body. The nominal pressure is PN1MPa;Z41T-10 stands for manual, flange connections, plain wedge single gate, sealing surface material is copper alloy, nominal pressure is PN1MPa.According to domestic valve model standards, the valve model is by the valve type, gate valve drive mode, gate valve connection, gate valve structure, sealing material, valve body material code to indicate

- Q: What are the differences between the gate valve and the cut-off valve?

- Is the gate valve opening and closing parts, RAM direction of motion perpendicular to the direction of the fluid, valve can only be fully open and fully closed, is not suitable for regulation and throttle. The gate has two sealing surfaces. The two sealing surfaces of the most commonly used wedge gate valves form a wedge. The wedge angle varies with valve parameters, usually 5o. Wedge gate valve can be made into a whole, called the rigid gate; can also be made to produce micro deformation of ram, in order to improve its process of deviation, make up the sealing surface angle in the process, the gate is called the flexible gate. Valve closed, the sealing surface can only rely on medium pressure to seal, that is to rely on medium pressure to the gate sealing surface pressure to the other side of the seat to ensure the sealing surface seal, which is self sealing. Most of the valve is forced seal, that is, when the valve closes, to rely on external force to force the gate to the seat, in order to ensure the sealing surface sealing.A stop valve is a valve that closes the valve and moves along the center line of the valve seat. According to this form of valve movement, the valve seat opening change is proportional to the valve stroke. Because of the valve stem to open or close the trip is relatively short, but very reliable cut off function, and because changes in the valve seat and the valve stroke is proportional, is very suitable for flow regulation. As a result, this type of valve is ideal for use as a shut-off or regulator and throttling

Send your message to us

DN65 Ductile Iron Rubber Gate Valve With Long Stem

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches