DN100 Cleaning Column For Concrete Delivery Pipe

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

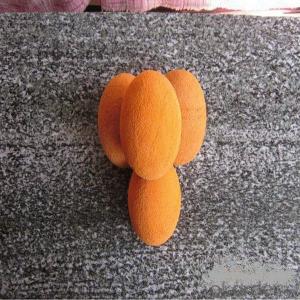

Concrete Pipeline Cleaning Ball

SIZE

Cleaning Ball --- DN80, DN100, DN125, DN150

Cleaning Column --- DN125, DN150

STYLE

Cleaning Ball --- hard type, soft type

Cleaning Column --- hard type

FUNCTION

Its main function is used for cleaning concrete pipeline.

PACKING

No.1 Export standard packing

No.2 Seaworthy packing

No.3 other ways or according to the customer demand

Feature

1. It is mainly used for cleaning all kinds of diameter of pump pipe cleaning tool,

maintenance of pipeline cleaning, made channel is more unblocked, unimpeded.

2. Greatly improving the work efficiency.

3. Prolong the service life of the various diameter pipe .

The main products

1. Concrete pump pipe :ST52 concrete pump pipe , 45Mn2 Wear resistant pipes, Twin wall pipes ,Reducer , tee, .ect.

2. the towed concrete pump, Concrete placing boom series.

3. Concrete pump truck fittings : Wear plate and wearring, Svalves, Concrete pump piston , delivery cylinder,.ect

4. Concrete pump clamp : DN80, DN100,DN125,DN150 Casting pipe clamp and Forged clamp.

5. Other accessories: Rubber hose , Cleaning ball , Sponge plug, Seal, The bearing seat, Flange etc.

- Q: What are the causes of cracks in vulcanized rubber products?

- When vulcanized rubber products are cracked, it shows that high sulfidation temperature, poor material flow, short scorch time, and partial scorch of rubber compound cause cracks.

- Q: Excuse me, is PU one kind of silicone? Or what is the connection between the two?

- First of all, PU does not belong to silica gel, and PU refers to polyurethane. It is a kind of macromolecule material which is made up of organic diisocyanate or polyisocyanate and two hydroxyl or polyhydroxy compound. And silica gel is a common organic silica gel. The basic structure of organic silica gel is made up of silicon oxygen link, and the side chain is connected with other organic groups through silicon atom. So, these are two very different materials that make up the system. But because of the wide application of the two, they intersect in some application fields.

- Q: What kind of rubber products are expensive?

- Other technologies, processes, and logistics all determine the cost

- Q: What is the definition of mixed rubber?

- Chemical property:Synthetic rubber is composed of different monomers under the action of the initiator, the polymerization of polymers of variety, monomer, styrene, butadiene acrylonitrile, isobutylene, chloroprene etc.. There are four kinds of polymerization process: emulsion polymerization, solution polymerization, suspension polymerization and bulk polymerization.

- Q: Several aspects of rubber aging performance and how to identify them

- Heat: increasing temperature can cause thermal cracking or thermal crosslinking of rubber. But the basic function of heat is activation. Increase oxygen diffusion rate and activate oxidation reaction, so as to accelerate the speed of rubber oxidation reaction, which is a common aging phenomenon - thermal oxidative aging

- Q: NR natural rubber manufacturers, who knows Guangdong here, there are manufacturers, a few hair connection is OK

- Natural rubber (NR) is mainly composed of rubber hydrocarbons (polyisoprene), containing a small amount of protein, water, resin acids, sugars and inorganic salts. The utility model has the advantages of large elasticity, high extension strength, high tear resistance and electrical insulation, good abrasion resistance and drought resistance, good processability, easy adhesion to other materials, and superior performance in synthetic rubber in comprehensive performance. The disadvantage is that oxygen and ozone resistance is poor, easy aging, metamorphism, oil and solvent resistance is not good, the first corrosion resistance of acid and base is low, heat resistance is not high. Temperature range: about 60 DEG C ~80. Make tires, rubber shoes, hose, tape, wire and cable insulation and sheath, and other general products. The utility model is especially suitable for making torsional vibration eliminator, engine shock absorber, machine support, rubber metal suspension element, diaphragm and molded product.

- Q: The silica gel of the kettle is the white one that is waterproof and leaked out

- Butadiene styrene rubber (SBR) copolymer of butadiene and styrene. Performance is close to natural rubber, is the largest yield of general-purpose synthetic rubber, characterized by wear resistance, aging resistance and heat resistance, more than natural rubber, texture is more natural rubber uniform. Disadvantages are: low elasticity, anti bending, anti tear performance is poor; the processing performance is poor, especially the poor, low strength self adhesive rubber. Temperature range: about 50 DEG C + 100. Mainly used instead of natural rubber to make tires, rubber sheets, hose, rubber shoes and other general products.

- Q: How can there be a crack in the rubber ring?

- Suggest:1, processing aids (stearic acid, paraffin wax or high molecular wax) increased appropriately!2, operating oil appropriate two plus -5 copies!3. Proper curing temperature. Select according to rheometer!4. Re adjust the parameters of the processed species (such as temperature, exhaust, material thickness, etc.)

- Q: How to distinguish between silicone hose and rubber tube by appearance?

- Silicone hose is relatively soft, flexible, and looks better than other rubber tube gloss, color is mostly red, blue, translucent and other colors. Others, such as three yuan ethylene propylene and nitrile rubber hose, are basically black.

- Q: What are the hazards of waste rubber and how can they be used for regeneration?

- In addition to piling up waste rubber products as fuel burning, scientists have been studying more effective waste rubber regeneration technology since 1910. Reclaimed rubber refers to the physical and chemical processes such as comminution, heating and mechanical treatment of waste vulcanized rubber, which can change from elastic state to vulcanized rubber with plasticity and viscosity. The essence of the regeneration process is the comprehensive effect in heat, oxygen, mechanical function and recycling agent of chemical and physical functions, make the network vulcanizate degradation, the fracture position of both crosslinks, also have large molecular cross-linking bond between. Rubber regeneration methods can be broadly divided into two categories: physical regeneration and chemical regeneration.

Send your message to us

DN100 Cleaning Column For Concrete Delivery Pipe

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords