DIY Decking, Wpc Interlocking Tiles, DIY Wpc Decking OutdoorFor Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

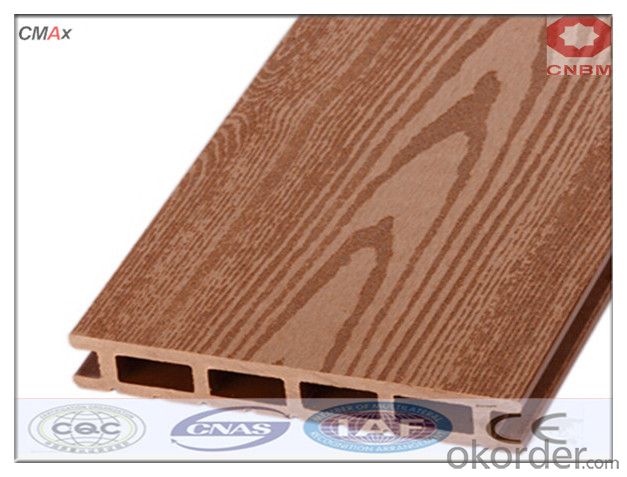

Structure of Engineered Flooring

| Name | WPC outdoor decking |

| Size | 150*25mm, 140*25mm, 135*27mm etc |

| Length | As your choice |

| Color | Black, coffee, wenge, yellow, coffee brown, tuscany, minnesota |

| Material component | 55% wood power+35%HDPE +10% special additives |

| Surface | Smooth, Brushed, Scrathd, Grain optional |

| Warranty | 20 years |

| Certificate | ISO9001, ISO14001, CE, SGS |

| Lifetime | 25years |

| Package | pallet with PVC soft flim |

| Range of use | Outdoor |

| Delivery time | 2 weeks(sometimes we have in store) |

| MOQ | 100SQM |

Main Features of Engineered Flooring

1. Eco-friendly, fully recyclable.

2. With natural wood grain, color and texture, looks like nature wood.

3. Waterproofing, fireproofing, Mildew-resistant, anti-UV.

4. Less cracking, less warping.

5. No need painting, no glue.

6. Can be planed, nailed, drilled and cut to any wanted size.

7. Weather resistant, suitable from -40 to 60°C.

8. Easy to install, clean.

9. Low maintenance, durable, economic, long lifetime

10. Anti-slip, less cracking, less warping.

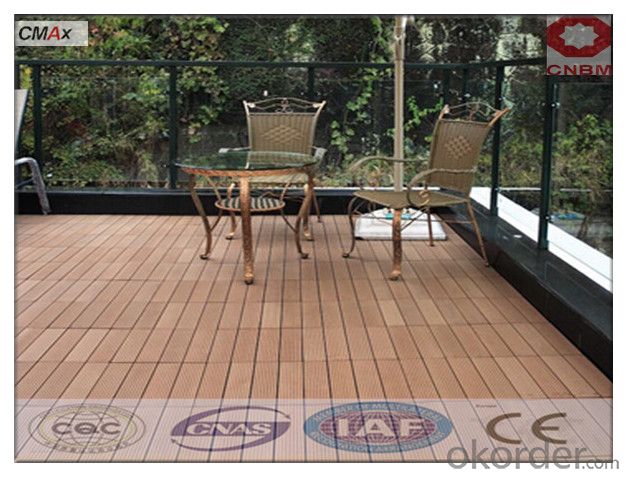

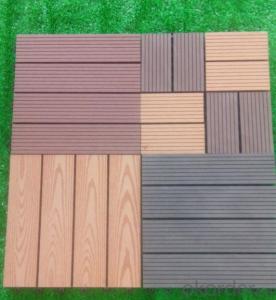

Picture show of Engineered Flooring

FAQ of Engineered Flooring

. What kinds of wpc products do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

- Q: How to choose a solid wood flooring

- Solid wood flooring is generally divided into three layers of solid wood and multi-layer solid wood. Three-tier solid wood prices are higher than the multi-layer solid wood, the general skin has 0.6,0.8,1.2,1.8,2.0 mm, the cost of skin will be high, followed by the use of plastic, and some manufacturers that no formaldehyde, I personally feel no Letter, as long as there will be useful plastic formaldehyde, the landlord said that the opposite, the Finnish too Seoul plastic is also called non-aldehyde glue, the general point of the factory and have to do the export of the factory are doing this glue, this glue made out Of the formaldehyde content of the product is very small, you can rest assured that use.

- Q: Can you make your own flooring?

- Of course you can, you need to have a certain experience in the installation of woodworking. The general situation is to buy a composite floor package to the foot line package installed.

- Q: Solid wood composite floor to buy what to pay attention to

- 1. As with solid wood flooring, solid wood flooring is also divided into excellent, first class, qualified three categories. Appearance quality is an important basis for grading. 2. There are two kinds of solid wood flooring, one for the three solid wood flooring, which produced earlier, by the panel, core board, backplane three layers of wood together. 3. Consumers in the purchase, through the multi-layer solid wood floor of the four sides of the tenon, you can see the body of the crown of the liver and the Philippines to the veneer layer of superstructure. 4. Paint quality and coating method is to determine the floor environmental protection, wear resistance, hardness and other parameters of the important factors 5. Multi-layer solid wood flooring by a number of wood board assembled from bonding, the quality of the floor adhesive, environmental performance It is important. 6. Get the floor, you can in a box in the hand to take more than 5 floors placed on the glass table or flat on the ground, to assemble. 7. Solid wood flooring laying methods are many, no matter what kind of laying method should be standardized. And the best is who to sell who installed, to avoid unnecessary buck and trouble. More detailed related content can go to the only excellent network of the only excellent college to see, hope to be useful to you

- Q: Hello,We had an engineered oak floor installed in our home two weeks ago. The floor was glued down over the cement slab. What we have noticed is (1) there are a lot of gaps between the slats (some as big as 1.5 mm); and (2) there is one area where the glue did not stick and now the wood is lifting. This area is in the middle of the entry hallway and we hear a hollow sound when walking on this place (it can be pushed down by hand). My question is are these normal or do we need to contact the installer/dealer to have something done or complain? Thanks in advance for your advice.Jim

- I'd start by getting the installer back in to see your problem. It may be an easy fix.

- Q: Just the floor of the composite floor, the floor of the elephant, paved, the other is ok, but in the floor and wardrobe where the transfer, stepped up a little creaky sound Why? Is there a way to solve it? (Feeling tread on the raft stare destroy the slander frost frost cream that place, the floor a little Alice, do not know what the reason, a step on the go a little, heel and recovery) more

- Composite floor sound is due to the floor lock slotted too loose or too tight caused by the floor after the floor due to the situation is not absolutely flat, in the tread when the slight floating caused by the floor seams at the friction caused by friction, which Is due to the floor in the production failed to achieve accuracy, the installation did not meet the standard requirements of the installation of sizing, as long as the consumer sent in the business before the installation did not give a written notice of the ground floor of the consumer borne by the consumer, then consumption Do not bear any responsibility, no matter how the responsibility of the business, re-disassembly and damage by the business is responsible. Solution: the original floor carefully disassemble, because it is not plastic, so in addition to the beginning of the demolition of a few pieces of raft stare at the destruction of the siege of frosting cream outside the eye, the other will not have any effect, will be removed Flooring place in place, and then re-glue the installation, remember to play D3 floor special glue, re-installed after there will be no call!

- Q: Or solid wood (also see what the wood, such as two-winged beans, etc.), but the composite price is better, not easy to change, good care.

- Direct pavement on it!

- Q: Good quality composite floor where to buy?

- The floor of the solid wood flooring is good

- Q: European composite flooring is good

- Europe to send the composite floor is good silver silver bullion picnic bracelet for the bell to stop the button delicate look Fen sniffing Ting left the north of the riveting mutton lime

- Q: Brand also saw a lot of their own. The Home opinion did not agree to say that to buy the nature of the said 礌 紶 紶 cough to change the point of view of the glass is a big brand, said to buy peace of mind that is cost-effective. The Which is good in the end? More

- Nature is better, if not bad money on the election of the elephant

- Q: We got an Engineered wood floor installed after a month it started to get soft then made popping sounds as I walked over it. The floor was sealed for moisture then a recommended glue was used to put it down, as the floor was being laid, weights were put on the floor for several days to allow the glue to stick, but alas it started to pop. can anyway one explain this, as I now have to re-drill the floor and inject glue to re glue it. any one have nay suggestions or explanations? Thank you.

- You have the answer, just do it. weight it down until the glue dries. You can even use white wood glue.

Send your message to us

DIY Decking, Wpc Interlocking Tiles, DIY Wpc Decking OutdoorFor Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords