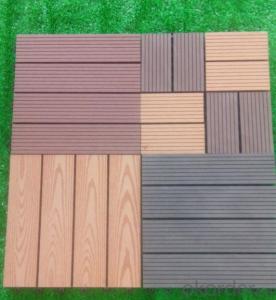

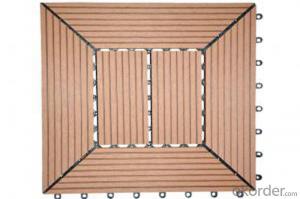

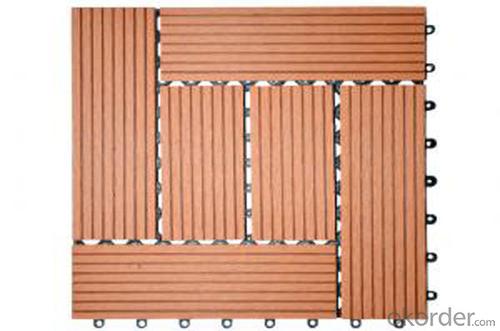

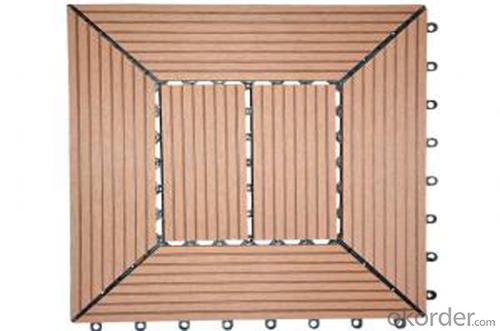

DIY WPC Interlocking Composite Decking Tiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of DIY WPC Interlocking Composite Decking Tiles:

A safe, environmentally responsible alternative to traditional decks, conserving energy and resources. Not only does this save your time over the maintenance, but it will save you money as well.

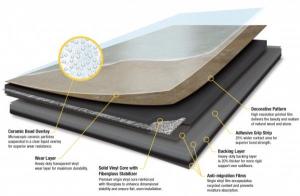

Composition of DIY WPC Interlocking Composite Decking Tiles:

30% HDPE+60% bamboo/wood fiber+10% Chemical additives.

Advantage of DIY WPC Interlocking Composite Decking Tiles:

· Maximum length: 6m

· UV resistance, durable

· Safe, environmentally responsible alternative to traditional decks, conserving energy and resources

· Low maintenance

· 100% recyclable

· Saves forest resources

· With look of natural wood but no timber problems

· Moisture/water-resistant

· No rotten, proven under salt water condition

· Barefoot friendly, anti-slip, no cracking and warping

· Requires no painting and glue

· Weather-resistant

· Termites, insects and moldy-proof

· Easy to install and clean

· Available in various colors

· Can be used in Temperature: -40 to +60°C

Installation of DIY WPC Interlocking Composite Decking Tiles:

Correct installation needs your high attention!

1 Always leave space (5-7mm) between 2 boards, or between board and wall.

2 Where there are 2 board ends meet, put 2 pcs of keels under each board end.

3 Keep the space of 2 keels at 25-750px.

4 Do not use glue to install.

5 Do not use our product where is always wet and sunless.

Other Information of DIY WPC Interlocking Composite Decking Tiles:

HS code: 3918909000

Time for production(1x20fcl): 15 days

Warranty: 10 years.

Certificate: CE, ISO

- Q: Wood floors and wood floors in the outdoor anticorrosion materials?

- Wood floor is a new type of environment-friendly wood plastic composite products, in the production process of medium and high density fiberboard in guaiacol, recycled plastic granulator made by adding wood plastic composites, then the extrusion group made of wood.

- Q: How to eliminate the smell of plastic floor

- Put the floor outside the room put the taste, if not, for the sake of the child's health or not as good, consider replacing other things.

- Q: Board PVC plastic floor plastic toxic

- PVC floor "refers to the use of polyvinyl chloride material production floor. Specifically to the polyvinyl chloride and its copolymerization resin as the main raw material, filler, plasticizer, stabilizer, coloring agent and other accessories, in the continuous sheet substrate, the coating process or by rolling or extrusion process and.

- Q: Construction process of soft plastic floor

- 1 scope of applicationThis technology is suitable for the construction of the plastic (plastic) floor surface of industrial and civil building.2 construction preparation

- Q: There is a layer of plastic on the floor of the room

- Plastic film paper, paint was laid on the ground! Hope to help you, hope to adopt!

- Q: Plastic foam flooring is not a large mosaic floor.

- You can put in a layer of foam on the floor quilt or blanket. This is safer. Foam floor dirty or a block of cleaning, more convenient.

- Q: How to spread plastic floor tiles

- Wet floor tile shop: cement and sand and water mixing into cement mortar (dry wet like rigid cement mortar plus a lot more). Before laying along the wall popped out of the ground elevation line, and then do the ash cake around the room, (ash cake is painted or pouring floor when Mason used to control the building elevation and surface flatness and verticality of cement blocks.) The surface of the cake should be lower than that of the floor, and the thickness of the floor tile should be lower. Finally, use a rubber hammer to crack down.

- Q: What is the difference between hard and soft plastic floor construction

- If I tell you, will you kill me? Well, tell you, in fact, the difference is not big, not fire

- Q: Spread a layer of plastic cloth under the wooden floor

- Wood flooring below you have plastic, also called moistureproof layer, and a layer of linoleum or plastic cloth, can cut off the ground condensation of water vapor, and let it pass around the foot of a wall left side seam, emitted into the air. Moisture proof material integrity, damage or joints should be repeated cover. Now some of the lower ground floor of the house to do a half basement treatment, can also play a better role in moisture.

- Q: Ijiali will be on the floor of the kind of plastic that is connected to a piece of letters, animal patterns, such as the name of what ah

- The ground cushion treasure is a new type of lightweight sheet made of polystyrene resin and other additives. The utility model has a continuous uniform and dense surface layer and a closed cell structure, and the wall of the honeycomb structure has the same thickness. Therefore, the utility model has the advantages of superior thermal insulation performance, good moisture resistance, long durability, high compression resistance and good sound insulation effect. And it is non-toxic environmentally friendly products.

Send your message to us

DIY WPC Interlocking Composite Decking Tiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords