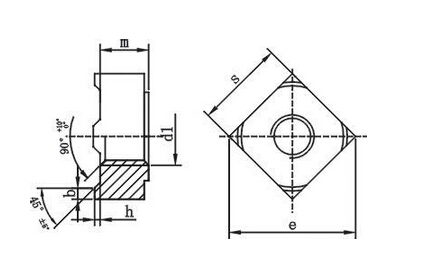

DIN928 Square Weld Nuts

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000000 piece/ pieces per month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name | DIN928 Square Weld Nuts |

Material | Carbon Steel, Stainless Steel 201/ 304/ 316 or others. |

Size | M4--M22 |

Standard Model | DIN ANSI JIS ASTM |

Min Order | 1000piece/ pieces |

Packaging & Shipping

Packing | Inner Box + Carton Box + Pallet or Under Your Requirement |

Supply capacity | 10000000 piece/ pieces per month |

Delivery time | 5~20 days after deposit |

Export market | Asia, America, Europe, Africa, markets. |

Our Services

1. Reliable Supplier |

2. High Quality |

3. Standard Producing Technology |

4. Competitive Factory Price |

5. Fast Delivery |

Product Picture:

- Q: Why the screw thread more closely, spin into the more effort?

- Screw thread more dense, indicating the screw thread deep and shallow, the screw in the advance the resistance of the smaller, when the spin naturally more effort.

- Q: The idiom of the screw

- Screw idiomatic meaning 1. work conscientiously, obey the organization, where I go, loyal to duty, Lei Feng's "screw spirit." 2. Individuals obey the whole: ordinary people or things, dry line of love and his party.

- Q: The mirror under the mirror put the toilet glass is broken, the original screw rust deformation, and pulled out. How to rust the screw

- The easiest way to change the place to hang the original place to hang a mural

- Q: Is the tail screw? If it is mainly used in what place? If not what are they different?

- This kind of screw called what I really do not know its name, the use of the place to see really not much, I see the place are generally used in machinery and equipment above, as you said what role, my personal point of view is To prevent slipping, because it is the head of a large slip wire, need to hand to adjust to the correct position to fall off, know that so much, not professional, Oh ~ hope to help you! The

- Q: M4.8 * 25 What does it mean in screw size?

- M4.8 is the screw size 25 is the length of the screw

- Q: No cross screwdriver, how can the screwdriver screwdriver?

- Some nail holes have depth, you can use the female (black vintage kind) steel wire card flat steel filing with a file to repair a little more can be a little more, if the nail in the plane, The use will also be on the.

- Q: For the commonly used standard parts, for some of the quality of good or bad, how to distinguish,

- Thread: Do not have chaos, roughness standards, internal and external thread test sets of each other about. search for

- Q: What fasteners are manufacturers in China?

- (11) Ningbo Ningli high-strength fasteners Ltd.(12) Ningbo Donggang Fastener Manufacturing Co., Ltd.

- Q: I am a trainee apprentice, recently encountered a problem, that is, some screws are screwdriver screwdriver or hexagon turned no thread. Can not buckle, only in the inside idle. What is the general use of this situation to open it? Thank you, more urgent.

- Drill holes, with a solid hard material grinding a screwdriver, it is embedded in the hole, so just back the thread. If the hole is too small can not drill, put the screw directly drill with a drill hole drill, drill bit and screw bottom hole the same size, and then attack the thread under the wire. It is not possible to change the number one thread.

- Q: How is the screw produced

- Annealing: the wire heated to the appropriate temperature, to maintain a certain time, and then slowly cooling to adjust the crystal structure, reduce hardness, improve the room temperature processing. Pickling: Remove the oxide film on the surface of the wire and form a layer of phosphate film on the metal surface to reduce the wire drawing and cold pier or forming process. To the required diameter. Practical for some products can be divided into coarse pumping (shelling) and fine pumping two stages. Molding: The wire is forged by cold forging (or hot forging) to achieve the shape and length (or thickness) of the finished product. The finished semi - finished product is rolled or tapped to achieve the desired thread. Practical for the bolt (screw) known as the rolling teeth, teeth known as the rolling teeth, nuts called tapping. Heat treatment: according to the object and the purpose of different different heat treatment can be used. Quenched and tempered steel: quenched high temperature tempering (500-650 ℃) spring steel: quenched after tempering temperature (420-520 ℃) ??carburizing steel: carburizing after quenching and then low temperature tempering (150-250 ℃) low carbon and In the carbon (alloy) steel quenched into martensite, with the tempered temperature rise, the general rule is the strength decreased, while the plasticity, toughness rise. Surface treatment: surface treatment that is through a certain method in the workpiece surface coating process, the purpose is to give the product surface appearance, anti-corrosion effect.

Send your message to us

DIN928 Square Weld Nuts

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000000 piece/ pieces per month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords