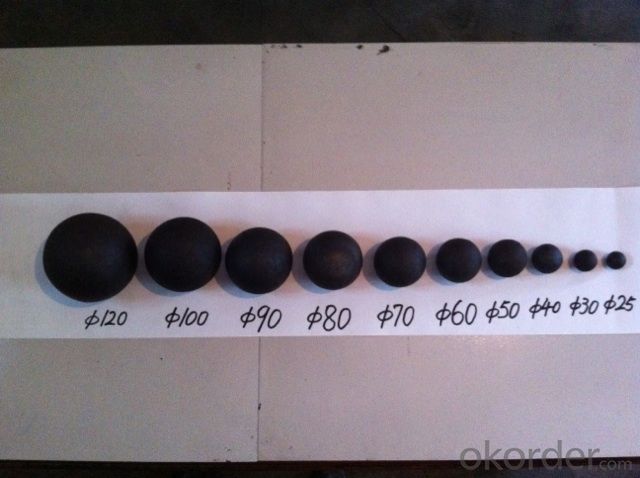

Dia.20-150MM HRC53-65 Hot Rolling Forged Grinding Media Ball Made in China Used for Mineral Processing

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MTS m.t.

- Supply Capability:

- 200000MTS/Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Dia.20-150MM HRC53-65 Hot Rolling Forged Grinding Media Ball Made in China Used

for Mineral Processing:

1.Grinding Ball Dia.20-150mm

2.Wear-resistant,High impact value

3.High combined efficiency

4.Hardness 55-65HRC

5.Low breakage

Features of Dia.20-150MM HRC53-65 Hot Rolling Forged Grinding Media Ball Made in China Used for

Mineral Processing:

1) In general, forged steel ball has high hardness: surface hardness to 55-68 HRC, volume hardness of 50-63 HRC

2) impact toughness high: impact toughness more than 12 J / cm2.

3) broken rate is low: the actual broken rate is not higher than 1%.

4) loss of grinding forged steel ball round rate is low.

Chemical Composition of Dia.20-150MM HRC53-65 Hot Rolling Forged Grinding Media Ball Made in

China Used for Mineral Processing:

Brand | Material | C | Mn | Si | Cr | S | P | V |

TITLE -1 | 50MN | 0.48-0.56 | 0.70-1.0 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 | |

TITLE -2 | 60MN | 0.57-0.65 | 0.70-1.0 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 | |

TITLE -3 | 65MN | 0.60-0.70 | 0.90-1.20 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 | |

TITLE -4 | 75Mn | 0.72-0.92 | 0.17-0.37 | 0.17-0.37 | 0.4-0.6 | ≤0.035 | ≤0.035 | |

TITLE -5 | 75MnCr | 0.70-0.85 | 0.7-0.8 | 0.17-0.37 | 0.2-0.7 | ≤0.03 | ≤0.03 | |

TITLE -6 | 75SiMn | 0.70-0.90 | 0.7-1.2 | 0.4-0.8 | ≤0.25 | ≤0.03 | ≤0.03 | |

TITLE -7 | Wear-resistant Alloy | 0.5-0.65 | 0.4-1.0 | 1.4-1.8 | 0.9-1.2 | ≤0.03 | ≤0.03 | 0.1-0.2 |

Chemical Composition of Dia.20-150MM HRC53-65 Casting Steel Grinding Media Ball Made in China Used

for Mineral Processing:

Name | Material | C | Si | Cr | Mn | S | P |

TITLE -8 | Cr-22-32% | 2.0-2.8 | ≤1.0 | 22-32 | 0.5-2.0 | ≤0.06 | ≤0.08 |

TITLE -9 | Cr-17-22% | 2.0-2.8 | ≤1.0 | 17-22 | 0.5-2.0 | ≤0.06 | ≤0.08 |

TITLE -10 | Cr-15-17% | 2.2-3.0 | ≤1.0 | 15-17 | 0.5-2.0 | ≤0.06 | ≤0.08 |

TITLE -11 | Cr-11-14% | 2.2-3.2 | ≤1.0 | 11-14 | 0.5-2.5 | ≤0.06 | ≤0.08 |

TITLE -12 | Cr-5-10% | 2.1-3.2 | ≤1.2 | 5-10 | 0.5-1.5 | ≤0.06 | ≤0.08 |

TITLE -13 | Cr-1.5-3% | 2.2-3.5 | ≤1.2 | 1.5-3 | 0.5-1.5 | ≤0.06 | ≤0.08 |

- Q: What is normalizing, annealing, tempering, quenching? What is the difference between forging parts and casting parts?

- The aim is to make the grain fine and distribute the carbide evenly. The difference between normalizing and annealing is that normalizing cooling rate is slightly faster than annealing cooling rate, so normalizing structure is finer than annealing structure, and its mechanical properties are also improved. In addition, normalizing furnace cooling does not occupy equipment and has higher productivity. Therefore, normalizing may be used instead of annealing as much as possible. The main application areas of normalizing are as follows: for low carbon steel, after normalizing, the hardness is slightly higher than that of annealing, and the toughness is better. It can be used as the pretreatment of cutting. Used for medium carbon steel, instead of quenching and tempering, as the final heat treatment, or as an induction heating method before surface hardening. Used for tool steel, bearing steel, carburizing steel, etc., it can eliminate or restrain the formation of network carbide, so as to obtain the good organization of spheroidizing annealing. For cast steel, the microstructure can be refined and the machinability can be improved. Used for large forgings, which can be used as final heat treatment, so as to avoid larger cracking tendency during quenching.

- Q: The casting defects of pores, trachoma how to repair?

- Metal repair can be used to fill the repair. Airhole 2mm following LT102 recommend the use of liquid metal repairing agent.

- Q: What is the reason for 304 stainless steel precision casting parts to be changed?

- 304 stainless steel is easier to change than ordinary steel. Because the 304 heat conductivity is lower than that of the low doped steel, the temperature is even more uneven, and 20% of the non ferrous elements also make the distribution of internal and external elements more uneven, hard and soft inside. Each of these two produces greater internal stresses, resulting in a variant.

- Q: What is the casting material?

- Kdl1588n said in detail, casting a lot of material, steel, iron, aluminum, copper, zinc, etc. can be, valuable, as well as gold and silver, the most common on cast steel and cast iron, cast aluminum and so on.

- Q: Would you please tell me how to use casting parts for a year?The cast of an aircraft wing needs to be put aside for a year before it breaks;Does anyone know why?

- 2, heat aging (artificial aging), also known as stress annealing, is to heat the casting to 550-650 degrees, insulation 2 - 4h, with the furnace cooling to 150 - 200T, and then baked.

- Q: Cause of choking of casting parts

- Is it boiling from the picture? Does it sound like a fire? If not, it's not choking. I feel like choking. The gas doesn't drain out

- Q: Why should pig iron be used in casting?

- Popular name is called pig iron, in fact, is a kind of cast iron without treatment, after casting, in iron elements to add other elements to improve casting performanceIt mainly improves the fluidity, reduces the melting point and reduces the shrinkage.Usually pure iron and cast iron at the eutectic point (about 4.7% carbon content) can be used for castingThere are many kinds of cast iron, usually grey cast iron, ductile iron and vermicular graphite iron......

- Q: Heat treatment process and purpose of casting parts

- Natural aging (also known as Chang Hua): lost in the open, the sun and rain, can have experienced years of wind and frost.

- Q: How to solve casting defect casting?

- Different defects, different solutions, some shortcomings, the current domestic level can not be resolved

- Q: Shandong foundry, casting small pieces of precision casting

- Small foundry in Shandong too much, like many of us in Qingdao, then Dongying Changshun investment casting is a home, they are also casting precision casting equipment, specifically what I recommend that local enterprises, far is not convenient,

1. Manufacturer Overview

| Location | Shandong,China |

| Year Established | 2000 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | Domestic Market, South Asia, Southern Europe, Northern Europe, Central America |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English;Chinese; |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Grinding Balls; Grinding Rods; Grinding Cylpebs. |

| Product Price Range | Average |

Send your message to us

Dia.20-150MM HRC53-65 Hot Rolling Forged Grinding Media Ball Made in China Used for Mineral Processing

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MTS m.t.

- Supply Capability:

- 200000MTS/Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords