Desiccant Masterbatch Defoaming Agent Anti-foam Agent for PP/PE Recycled Plastic Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

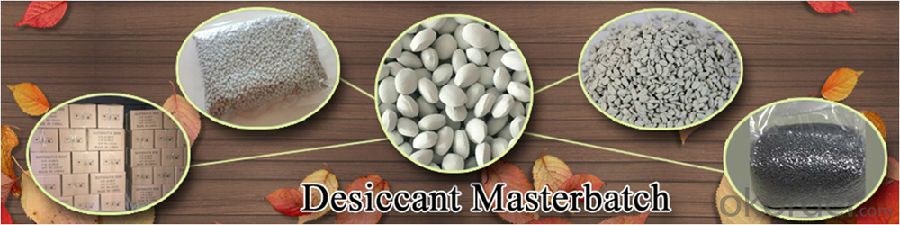

Desiccant masterbatch (also called defoaming agent, anti foam agent ).

It is suitable for all kinds of enterprises which make product with PP/PE recycled plastic material.

The bubble ,moire fringe, crack ,stain problems will be solved by adding efficient anti-foam masterbatch .

Application Method:

Production process can be achieved by mixing this masterbatch with damp plastic materials symmetrical. 1%--2% amount is recommended in blow molding,2%-5% is recommended in sheet and injection molding.

Customers decide the amount according to the condition of plastic dampness.

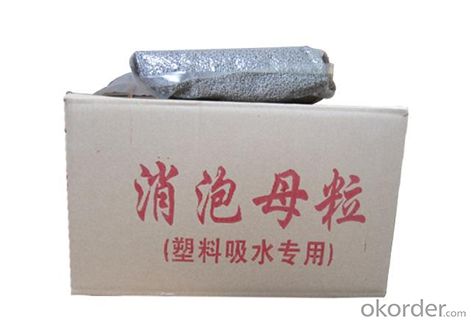

Packaging:Vacuum package, 2.5kg or 5 kg of each, it can not be store open,keep out of sunny peacan.

Advantage of Desiccant Masterbatch:

1.This series color masterbatches are of high concentration pigment with bright colors.

2.When they are used in resins, it shows better dispersing and stablility performance.

3.Also the mixture has the highest mechanical intensity preservation rate.

4.A broad standard color range available from stock as well as tailor made products develop according to customer requirements.

Features of Desiccant Masterbatch:

-Standard, universal, or custom colors

-Carriers optimized for easy processing

-Production orders shipped in 5 days

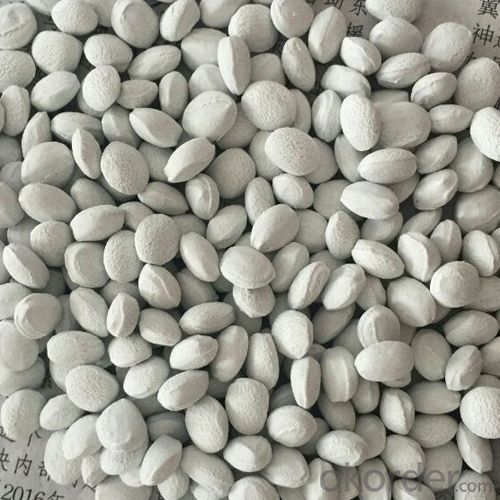

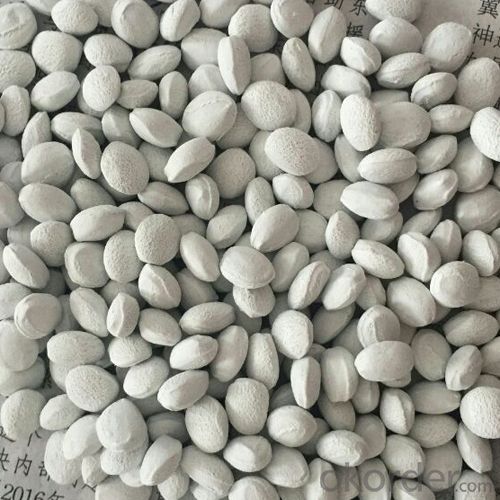

Product Pictures of Desiccant Masterbatch:

- Q: What are the common raw materials used in plastic bottles? What are the main features?

- PP bottles are non-toxic, transparent, and have certain heat resistance and impact resistance. They are generally loaded with fruit juice and shampoo. They can be hot filled (very important for fruit juice drinks). They can not be sterilized by pressure cookers, and their transparency is poor.

- Q: Low pressure plastic raw materials in the process of blowing the two sides of the fold, how to deal with?

- Blow up ratio of transverse expansion ratio of the film, is actually on the orientation of the transverse tensile film, tension will have a certain degree of plastic molecules, the blowing ratio is increased, thereby improve the lateral strength of thin films.

- Q: How many types of plastics are there?

- Name: ABS engineering plastics, can be used for connecting piece, seat back, seat board, it is able to perform plastic electroplating (water plating) the main raw material.

- Q: Plastic raw materials packaging is generally divided into several categories?

- 1, cattle cardboard fiber bag; "such as: GPPS, HIPS CMO ABS, are using this package, he is in some plastic packaging,2, fiber bags, plastic bags, such as PP or PVC, PE and so on3, plastic bags, Exxon, Teijin etc.4, plastic bags contain tin and platinum paper, for sealing requirements or moisture absorption of the material packaging5, kraft paper bags, PBT, PET, PPS, PA and so on

- Q: What is the material of plastic flat screen?

- It is made of hot spraying and cold fixing. It has the characteristics of wear resistance, corrosion resistance, toughness and so on. It can be used as a substitute for wire. The utility model has the advantages of corrosion resistance, light weight, long service life, no poison, no smell and good transparency.

- Q: How to make plastic raw materials?

- polyethyleneFor short, PE is a thermoplastic resin made by the polymerization of ethylene. Industrially, it also includes copolymers of ethylene with a small amount of alpha olefins. Polyethylene is odorless, non-toxic, feel like wax, has excellent resistance to low temperature performance (minimum temperature can reach -70 ~ -100 C), good chemical stability, erosion resistance to most acid-base (not resistant to oxidizing acid), insoluble in common solvents at room temperature, low water absorption, excellent electrical insulation properties; but polyethylene for environmental stress (chemical and mechanical function) is very sensitive, heat aging resistance difference. The properties of polyethylene vary depending on the molecular structure and density. The products of different densities (0.91 ~ 0.96g / cm3) can be obtained by different production methods. Polyethylene can be used as a general thermoplastic forming method (see plastic processing). Widely used, it is mainly used for making films, containers, pipes, monofilament, wires, cables, daily necessities, etc., and can be used as high frequency insulating materials for television, radar and so on. With the development of petrochemical industry, polyethylene production has been developed rapidly, and the output is about 1/4 of the total plastic output. In 1983, the total production capacity of polyethylene in the world was 24.65Mt, and the capacity of the equipment under construction was 3.16Mt.

- Q: How to identify the proportion of nozzle material in plastic?

- The melt index is detected by a melt flow rate analyzer. If the nozzle is added, the melt index will generally increase

- Q: Characteristics and uses of CA plastics

- Cellulose acetate (Cellulose Acetate, hereinafter referred to as CA, or cellulose acetate, cellulose acetate) was first prepared in 1865 and is the acetate of cellulose. CA used for photographic film base, is a component of some adhesive for synthetic fiber.

- Q: What does plastic material include?

- Plastic bags are the main raw materials of polyethylene and polyvinyl chloride, are non degradable. The main raw material for the production of plastic bags and polystyrene, polypropylene polymer, waste plastic packaging into the environment, because of its difficult degradation, will cause deep ecological environment problems, the long time. Waste plastic packaging is mixed in the soil, affecting crops absorb nutrients and moisture, will lead to crop failures; abandoned waste plastic packaging on land or in the water, animal as food ingestion, will lead to the death of the animal.

- Q: What is the raw material for producing high temperature polyethylene plastic bags?

- Adding nano scale montmorillonite can meet your requirements, forming a nanocomposite of polyethylene montmorillonite.

Send your message to us

Desiccant Masterbatch Defoaming Agent Anti-foam Agent for PP/PE Recycled Plastic Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords