Plastic Sheets - Decorative and Anti-Corrosion PVC Foam Board for Furniture

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

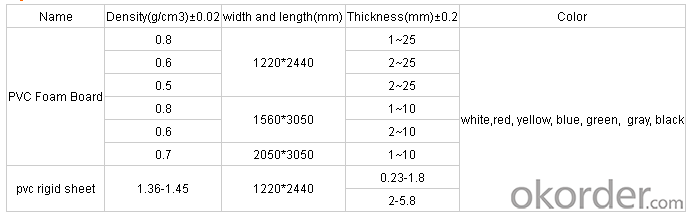

PVC foam board is made from polyvinyl chloride, with flat plate surface; it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof, anticorrosive, metabolic and recyclable, moisture resistant, lightweight.

Product Features

•Superior sealing and welding

•Excellent impact strength

•Higher processing yields

•Non-sticky

•Excellent printability with all common printing methods

•Available in a range of tints and transparent and opaque colours

•Range of surface finishes (Glossy/Matt)

Product Application

Construction: show window, doors, light-absorbing shade, telephone booth.

Advertisement: Lamp-house,signboard,indicator,display rack.

vehicle: door and window of car and train.

Medical: infant incubator, many kinds of medical apparatus.

Civilian goods: bath room, art work, cosmetics, bracket.

Industrial: instruments and meters and protecting cover

Characteristics

(1) Light weight

(2) High strength

(3) Easily cleaned

(4) Easily fabricated

(5) Outstanding print-ability

(6) Uniform fine close cell structure

(7) Good resistance to light and weathering

(8) Low flammability

FAQ

1. Sample: Can I get samples?

Yes, samples are available and can be provided free of charge, customer only need to pay for the shipping cost.

2. Is OEM or Custom Order available?

Yes, we can do custom order according to drawings or photos or samples.

3. Which Payment Terms?

Ali Trade Assurance, T/T(Telegraphic Transfer), West Union, L/C etc.

- Q: How to distinguish the plate and plastic glasses frame? That kind of material is better.

- Plastic sheet and vinyl products are plastic glasses refers to the so-called plastic injection moulding glasses, while the sheet is the use of high pressure molding and cutting into the spectacle frame plate frames of high temperature resistance, not easily broken, deformation, can protect the good lens; another sheet in texture and wearing comfort is far superior to plastic infusion frame, plastic frame also has its own advantages, such as low cost, great variety etc.

- Q: I want to renovate my basement, but as I was walking through my local hardware store, I noticed a variety of sheetrock that are mold resistant to fire resistent and at different thicknesses. Is a thicker board better for the basement?Also, is there a way to test moisture in a basement over sheetrock or would I have to remove the sheetrock and apply a plastic sheet with tape to test for moisture?thanks!

- You should really use mold retardant sheetrock in the basement. It might actually be required by code depending on where you live. I helped a guy fix up a house and the inspector told him to sheetrock the ceiling of the basement and use 1/2 mold resistant sheetrock. The differences you get with thickness of sheetrock is mostly durability. Obviously thicker sheetrock will hold up longer. On ceilings especially, the 3/8 inch sheetrock will bend over time between the rafters (or floor joists in the basement) where it is screwed in. There is also a difference in sound-proofing, you hear less through walls of 5/8 than 3/8. The last difference is fire resistance, 5/8 inch sheetrock takes significantly longer for fire to burn through than 3/8. To chose which one you want to use, find out what the code requires in your area. You may be required to use mold resistant sheetrock, or you may be required to use fire resistant boards. I would use 1/2 in the basement because it is a lot easier to hang than 5/8 and you have decent durability and unlike 3/8, it will not bend or bow over time. I actually saw mold resistant fiber tape for the joints in The Home Depot, you might want to use that whether or not it's required by code just for extra measure. Some things may be more expensive to do to the tee, but if you cheap out now, you may end up pending more fixing things if they go wrong or get messed up later down the road. And most importantly, do every single thing to code and pull permits for everything, that way you are covered on all your bases.

- Q: what is the overlayer plastic sheet used on standard dvd and game case called?

- that's thoroughly pointless, i think of people might desire to easily be able to purchase video clips of On call for or Verizon and function the flexibility to maintain them continuously on like a saved folder, and then with comparable song on Itunes and vehicles might desire to come put in with iPod holders so which you will play that rather of CD's, haha I even have weird and wonderful philosophy.

- Q: I will be adding a dehumidifier in the spring.

- Your okay, I would not replace it. The plastic sheeting is just doing it's job. Regards, Dale

- Q: What's the best glue for a plastic plate?

- Plastic board bonding, first of all to determine what plastic is plastic If not PP, PE; you can choose a lot of glue, look at your request, instant glue, AB glue, silicone can;If it is PP, PE will use a dedicated glue, and I have PP, PE adhesive glue, for PP, PE bonding strength is very good, not crisp, not hard, capable of high temperature 200 degrees, waterproof seal;

- Q: Plastic gusset plate how to install the diagram?

- Mounting boom. The installation should meet several requirements: first, and the bearing capacity of the hangers should be straight enough; secondly, we should advance to suspender rust; boom from the keel end shall not exceed 300mm, otherwise should be added if you need additional boom, boom, best lap welding, the main keel to avoid falling;

- Q: I have an 08 Hyperlite Era board that has a big problem. the top plastic sheet is peeling off at the edges and it is dragging in the water bad. i dont want to buy a new board but i cant fix it. I have already tried a permanent epoxy-resin but it was destroyed after the first use. I am now thinking of shrink wrapping a resin type plastic onto the whole edge but i dont know what i am doing. Does anybody have any suggestions?

- Try going back to epoxy and try again. This time prep the surfaces by sanding with a fairly fine sand paper, and make sure all surfaces are dry. If you attempt to epoxy to either a too smooth surface, a water wetted surface or a surface that has another wax or adhesive on it the epoxy won't adhere properly. Clean and sand the surfaces first and the epoxy should be stronger than new. Good luck with your repair..

- Q: Are plastic sheets transparent to UV light?

- Yes, plastic sheets can be transparent to UV light depending on the specific type of plastic used.

- Q: Are plastic sheets recyclable?

- Yes, plastic sheets are recyclable. However, it depends on the type of plastic sheet and the recycling facilities available in your area. It is important to check with your local recycling guidelines to ensure proper disposal and recycling methods for plastic sheets.

- Q: It's flat, like paper, but with a layer of plastic over top of it that has grooves into it that refracts the image printed on the paper. You used to get them in cereal/crackerjack boxes, or printed on a child's plastic ruler, or sometimes even the cover of a book would have them. Depending on the angle that you hold them, you see different images. You could tip them back and forth to produce a little 5 or 6 frame animation. Or some of them even let you see some basic 3D stereoscopic images. You don't need to wear 3D glasses or anything, it's just a flat thing.What's that technology called? I'm trying to find info about them and I don't know what they're called. Is there a company that will make them for me?

- It's called autostereoscopy. The grooved plastic is either a lenticular lens or parallax barrier

Send your message to us

Plastic Sheets - Decorative and Anti-Corrosion PVC Foam Board for Furniture

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords