Customized Widely Used Competitive Price Spunlace Non Woven Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are recognized as a reliable Manufacturer, Exporter and Supplier of Non Woven Fabric. We can provide Non Woven Fabric in any gram/m2 and any colour required by customer. Non Woven Fabrics are broadly defined as sheet or web structures bonded together by entangling fiber or filaments (and by perforating films) mechanically, thermally or chemically. PP Spun bonded Non woven Fabrics are produced using a precise extrusion-based technology. The polymer is stretched into a continuous filament and loosely spread onto a conveyor belt to form the web. Air is used to form and lay the fabric filaments. On the other hand, some non woven fabrics can be recycled after use, given the proper treatment and facilities.

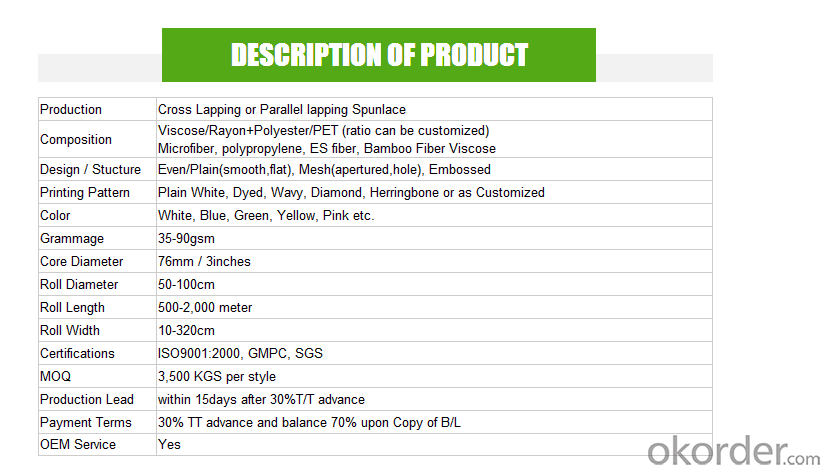

Product Specifications

Weight: 10 - 150 gsm

Width: Max 1600 mm (can be slit)

Fabric Roll Length: As per buyer’s need ( 200 - 1200 Mtr)

Color: various colors available.

Procedure of production: Spun bonded Non Woven, Diamond design

Material: polypropylene

Minimum Order: 1000 Kg

Sample: sample free, freight collect

Product Application

Non woven fabric manufacturers usually manufacture the fabric in a roll form. It is then sent to various other industries where it has end applications, where is it cut and given different form depending upon the use. They can also be used in combination with different materials and offer a wide range of products.

Colored Non woven fabrics are use in many sectors and variety of applications, such as Health, Hygiene, Medical, Packaging, Agriculture, Furniture Upholstery, Geo Textiles, Leather Industry, Shoes and Garments. Customers come from the textile and automotive industries as well as many other sectors.

- Q: What is the amount of alkali in the textile mill

- Properly corroded some potholes of small grooves, you can improve the polyester smooth, rigid appearance, so that feel soft, close to the feeling of silk. This process is called reduction processing.

- Q: Textile industry belongs to the first few industries

- The first industry in the "classification of national economic industry" (GB / T 4754-2002), a category that is Class A, including agriculture, forestry, animal husbandry, fisheries and agriculture, forestry, animal husbandry, fishing services a total of five categories; Mining and salt industry into the secondary industry.

- Q: What are the Advantages and Disadvantages of PE and PVC in Textile Fabrics

- With non-flammability, high strength, weather resistance and excellent geometric stability.

- Q: Textile finishing TPU, TPEF film. What's the difference?

- Both the performance is almost the same, but the former more environmentally friendly, as follows

- Q: What are the invoices for the textile industry?

- If you are the general taxpayer of the production type, the raw material of the purchased textile is the incoming invoice

- Q: What are the policy measures developed by the Bangladeshi government for their exports?

- As the country's textile has a long history, coupled with the government's rational and orderly development strategy of the textile industry, Bangladesh is increasingly becoming a textile country in Asia. The textile industry is one of the major manufacturing industries in Meng.

- Q: Textile enterprises to operate the project: processing and production are different?

- While the latter is the production of independent arrangements, that is, the production of products is based on the market or orders or contracts and other arrangements.

- Q: What are the classification of the textile?

- Cotton spinning silk processing linen wool chemical fiber can also be divided according to the weaving method: knitted woven nonwoven

- Q: Application of Biological Enzyme in Textile Processing

- Glucose oxidase in the textile processing applications: glucose oxidase mainly for fabric bleaching finishing, this enzyme treatment of hydrogen peroxide production is very effective, the treatment does not require the addition of hydrogen peroxide stabilizer, the fabric after the handle feel soft and plump.

- Q: What is the imo standard in the textile industry?

- The IMO certification will specify the requirements to ensure that the organic status of the textile, from the harvest of raw materials, to the annotations of environmental and social responsibility manufacturing, is to provide credible guarantees to the end consumer.

Send your message to us

Customized Widely Used Competitive Price Spunlace Non Woven Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches