CPG-6F Automatic In-line Capping machine Made In China Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Product Details

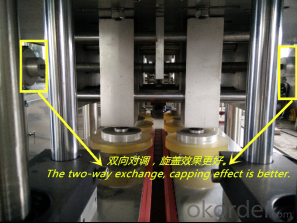

JCP-6A In-line Structure Capping Machine is making up with cap sorter, cap falling rail, bottle-tightening structure and capping wheels. By the tightening of the belts, the bottles finish the movement of cap scratch, push and capping. It applies to the capping of round and flat bottles. This capping machine is with easy structure and adjustment. When changing the bottle type, you do not need to change the spare part, only adjustment is enough.

2、Features

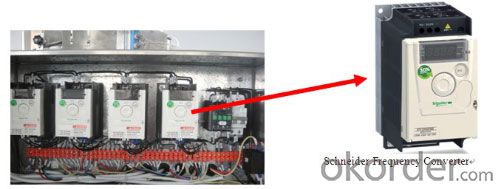

2.1 The whole machine uses Schneider brand which can make sure the stability of the machine.

2.2 A cap sensor is installed in the cap hopper. When there is not enough cap, the elevator will start working to make sure providing caps.

JPACKS Centrifugal Cap Sorting Bowl is also a great solution for high speed sorting and noise reduction for both flat, non-flat and specialty caps.

Specifications:

Custom tooling available

Optional diameters to accommodate varying cap sizes and types

2.3 Use a handle to adjust the height and tight of the machine,stable and reliable.

2.4 A mirror is installed to check the state of caps.

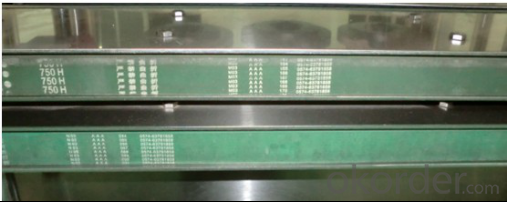

2.5 The tightening belt can last for a very long time.

2.6 The capping wheels with new material can last for a very long time.

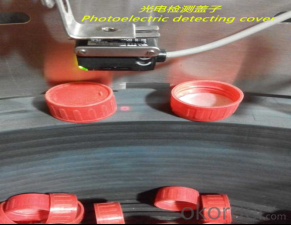

2.7 Intectual blow back lid system

Intectual checking back lid, high-speed magnetic valve rejector, solving the noise polluction, large comsumption of air and low qualified rate. Convenient adjustment.

3、Main Technology Parameter

3.1 Capacity:≤8000 Bottles/hour

3.2 Applicable Bottle Diameter:Φ35-96mm Bottle height: 80-230mm

3.3 Cap Specification:Φ12-50mm Cap height: 15-40mm

3.4 Air Pressure:0.5~0.7 MPA

3.5 Power Source:~220V、50HZ

3.6 Power:2KW

3.7 Weight:about 650Kg

3.8 External Dimension:2000×950×2100mm(L×W×H)

4、Images

FAQ

Q1: What is your delivery time?

A: Generally, the delivery time is 45-60 days after receive the deposit, big production line may take more time.

Q2: What is the payment term?

A: We accept both T/T and L/C. Most customers pay by T/T.

Q3: What kind of after-sevices do you provide?

A: If it is not big problem, we can solve it by emails, phone etc. If it can’t work, our engineers can go to overseas to install and adjust the machine and solve the problems.

- Q: What is the charge for packing materials?

- Included in the purchase of goods purchased by the cost, such as material in transit, fixed assets, raw materials and so on, but in the material to the buyer designated place, because the buyer's own reasons again the transport costs included in administrative expenses.

- Q: Paper bags, milk and plastic bags. What's the difference between milk and paper bags?

- The sterilization methods are different......Plastic bags of milk, that is, the use of bus sterilization, is the most do not destroy the milk in the nutrition of the way ~ is also very cheap, in general, buy that kind of milk to drink for a long time ~!The bag is Tetra Pak pillow packaging milk...... with the ultra high temperature sterilization, the sterilization ratio of bus destroys nutrients ~ and will make the lactose coking, to taste, to which + essence, in order to extend shelf life, go inside ~ + preservativeSo, I suggest that we buy plastic packaging milk, cheap and good ~!

- Q: What are biodegradable packaging materials?

- Synthetic biodegradable packaging materials can be endowed with similar properties as traditional packaging materials, and the wide application of biodegradable packaging indicates its great potential to replace the current packaging materials.

- Q: What advantage does PET material have in packing?

- As a packaging material, PET has good mechanical properties, and its impact strength is 3~5 times of that of other films. It has good folding resistance

- Q: How to prevent the use of packaging materials during production without error?

- Strengthen supervision, special packaging materials can be set up straight personnel.Management must be one to one or one to many, not many to one management. Otherwise easily confused.Do a good job of late entry, ensure that products correspond to their place.I hope I can help you.

- Q: What are the sales packing materials?

- Sales of packaging materials are generally an ordinary white paper, copy paper, crepe paper, bubble paper, poly velvet, pearl cotton, sponge, plastic bags PP, PE, OPP, PVC, PVA, shrink film (PE and PP).

- Q: What are the commonly used packing materials?

- Other packaging materials / materials: Materials: gilding bronzing material laser film anodized aluminum foil paper bronzing film film foil stamping foil foil adhesive, coating adhesive adhesive composite rubber reinforcing agent: starch adhesive sealing rubber latex resin

- Q: What kind of fruit package do you have?

- The fruit packing container can be divided into transportation package, storage package and sale package according to its use.

- Q: What's the difference between a package and a package?

- Packaging refers to the packaging of various types of containers, such as barrels, boxes, bags, bottles, etc., for the purpose of packing the goods of this enterprise. Packaging materials, such as paper, rope, wire, iron sheet, etc., these are disposable packaging materials, should be used as raw materials for accounting. Accounting items; turnover materials - packaging

- Q: What's the function of pearl cotton packing material?

- EPE pearl cotton foam material is a new kind of environmental protection packing and filling material. Its advantages are more and more recognized by people, so its use will continue to expand and innovate. Especially in the packaging and other industrial materials, it is better than the traditional wood performance, lower cost, higher grade, elegant appearance, better effect.

Send your message to us

CPG-6F Automatic In-line Capping machine Made In China Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords