Typar Continuous Filament Woven Geotextile/Geotextiles

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Continuous Filament Woven Geotextile/Geotextiles

Desciriptions:

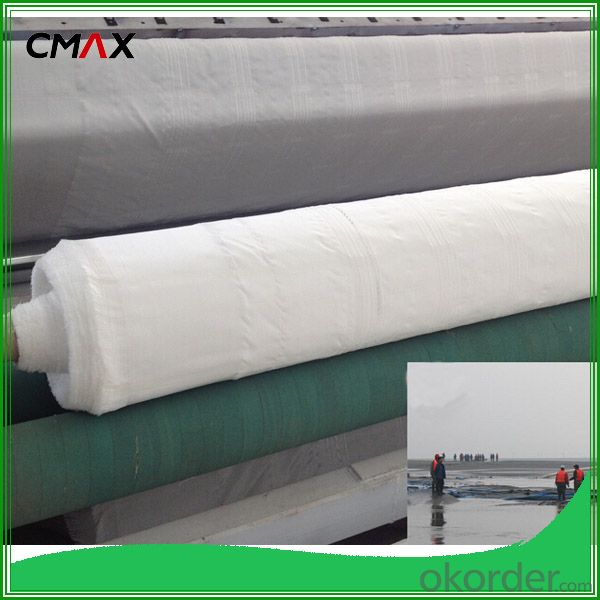

PP Woven Geotextile Professioal Waterproof Geotextiles. A woven geotextiles is an economical solution for any civil engineering applications. It separates, stabilizes, and reinforces soils and allos allows for filtration. Woven geotextiles are manufactured by extruding polypropylene film and then slitting the film into individual yarns which are then woven to form the geotextiles.

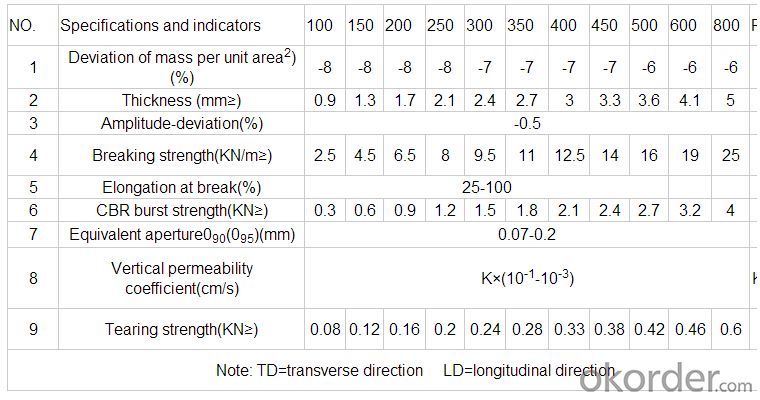

Specifications and Technical datas:

| Weight / Mass | 100gsm - 2000gsm/m2 |

| width | Within 8 m |

| longth | 50-100m/roll (at request) |

| Material | PP / PET |

| Color | Black , white , grey |

| Certification | CE/ISO9001 |

| Manufacturing method | nonwoven / woven |

Characteristics:

Easy process and high output rates

Excellent distribution of carbon black

Consistent quality and low failure rate

Excellent resistance and good waterproof ability

Good welding

Details of our products:

Produce process:

Applications:

1) Filtration :

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation :

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3) Adding muscle :

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4) Protection :

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

Packing and shipping:

1. The outer package: black or white woven geotextile.or we can make the package as your requst.

2. Different tgram/ roll size for different qty in the same containers.

3. Roll size: 3.95m*200 for container

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: Are geotextiles suitable for use in wetlands?

- Yes, geotextiles are suitable for use in wetlands. They are commonly used to stabilize soil, control erosion, and promote vegetation growth in wetland areas. Geotextiles can help retain moisture, filter water, and provide support to prevent soil movement. Additionally, they are often biodegradable or made from natural materials, making them environmentally friendly and suitable for use in wetland ecosystems.

- Q: Geotextile, geomembrane to go to the laboratory test

- Need, Huazhi geotechnical materials to solve manufacturers

- Q: Under what circumstances drainage pipes need additional geotextiles

- Infiltration of water under the circumstances, geotextile play a filtering effect, Huazhi geotextile material manufacturers

- Q: 300 grams per square meter of anti-geotextile there? what price

- Hello, 300 grams of geotextile with less, the best near the purchase of the specific price of the price can be a private letter or telephone I Hua Zhi geotextile material manufacturers for you to answer

- Q: Water stability grassroots health permeable geotextile or plastic film is good?

- 1, geotextile cloth, high unit price. 2, plastic film poor maintenance, generally do not. 3, moisturizing cotton, grass mountain child with more.

- Q: How do geotextiles help with reinforcement of geogrid wall systems?

- Geotextiles help with the reinforcement of geogrid wall systems by providing additional strength and stability to the structure. They act as a separator between the soil layers and the geogrid, preventing soil migration and maintaining the integrity of the wall system. Geotextiles also distribute loads evenly across the geogrid, reducing the risk of localized failures and improving overall performance and durability of the reinforced wall.

- Q: What are the advantages of using geotextiles in groundwater protection systems?

- Geotextiles offer several advantages in groundwater protection systems. Firstly, they act as a barrier that prevents soil erosion, thus maintaining the integrity of the groundwater system. Secondly, geotextiles can effectively filter and separate different soil layers, preventing the migration of fine particles and contaminants into the groundwater. Additionally, these textiles have high permeability, allowing water to flow through while retaining solid particles and pollutants. This enhances the overall quality of the groundwater by reducing the presence of harmful substances. Moreover, geotextiles are durable, resistant to biological degradation, and have a long lifespan, making them a cost-effective solution for long-term groundwater protection.

- Q: How do geotextiles help with siltation control in construction sites?

- Geotextiles help with siltation control in construction sites by acting as a barrier, preventing sediment from washing away and polluting nearby water bodies. They retain soil particles while allowing water to pass through, thus reducing erosion and maintaining the stability of the construction site.

- Q: What kind of geotextile is used to repair the road?

- Call one three seven to understand three one two one two to ensure that the quality of price satisfaction

- Q: Can geotextiles be used in shoreline stabilization projects?

- Yes, geotextiles can be used in shoreline stabilization projects. Geotextiles are commonly employed as erosion control measures in shoreline stabilization projects due to their ability to prevent soil erosion, enhance drainage, and provide structural support to the shoreline. They are often used to reinforce slopes, stabilize shorelines, and mitigate the effects of wave action, making them a valuable tool in coastal engineering.

Send your message to us

Typar Continuous Filament Woven Geotextile/Geotextiles

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords