Geotextile Bricoman - Continuous Filament Spunbond Needle Punched Polypropylene or Polyester Geotextiles

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 120000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Continuous Filament Spunbond Needle Punched Polypropylene or Polyester Geotextiles for Construction Use

1. Introduction of Continuous Filament Spunbond Needle Punched Polypropylene or Polyester Geotextiles for Construction Use

Filament woven geotextile: It is made of high strength polypropylene, polyester, nylon or mixed them together, all of which keep the original strength.

They were wovened together to form the pilotaxitic texture, which can keep certain structure and improve the original strength, It is widely used in river, coast, harbour, highway, railway, wharf, tunnel, bridge and other geotechnical engineering.

The woven geotextile is a invaluable product and can be used for different kinds of request, for example, filtrition, seperation, reinforcement, protection and others.

2. Property of Continuous Filament Spunbond Needle Punched Polypropylene or Polyester Geotextiles for Construction Use

High strength: Low deformation

Durability: Steady property, not easy to resolved, air-slaked and can keep the original property long term,

Anti-erosion: Anti-acid, anti-alkali, resist insects and mould.

Permeability: The woven geotextile can control the sieve size to retain certain permeability.

3. Specifications of Continuous Filament Spunbond Needle Punched Polypropylene or Polyester Geotextiles for Construction Use

Specification: 100g/m2-800g/m2

Material: Polypropylene or Polyester

Width: 1-7m

Length: 50-100m or as request

Color: White

Certificate: ISO9001 ISO14001 BV

4. Technical Data of Continuous Filament Spunbond Needle Punched Polypropylene or Polyester Geotextiles for Construction Use

PP Polypropylene Pet Polyester Continuous Filament Woven Geotextile | |||||||||||

Physical Properties | Test method | Unit | Typical Value | ||||||||

Material | Polyester/Polypropylene | ||||||||||

Unit Weight | ASTM D 5261 | g/m2 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1300 |

Color | White | ||||||||||

Mechanical Properties | |||||||||||

Tensile strength at break MD | ASTM D 4595 | KN/M ≥ | 50 | 75 | 100 | 130 | 160 | 180 | 200 | 230 | 360 |

Tensile strength at break CD | ASTM D 4595 | KN/M ≥ | 35 | 52 | 70 | 90 | 112 | 126 | 140 | 160 | 280 |

Elongation at break MD | ASTM D 4595 | % ≤ | 35 | 35 | 35 | 35 | 35 | 35 | 35 | 35 | 35 |

Elongation at break CD | ASTM D 4595 | % ≤ | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 |

CBR Puncture Strength | ASTM D 6241 | KN | 4 | 6.9 | 11 | 14 | 18 | 20.5 | 23 | 24 | 28 |

Tear Strength | ASTM D 4533 | KN | 0.6 | 1 | 1.3 | 1.6 | 1.9 | 2 | 2.2 | 2.3 | 3.2 |

Hydraulic Properties | |||||||||||

Permitivity | ASTM D 4491 | S-1 | 0.01-0.8 | ||||||||

Pore opening size O90 | ASTM D 4751 | mm | 0.06-0.7 | ||||||||

Width:max 5.4m standard 3.6m other colors available | |||||||||||

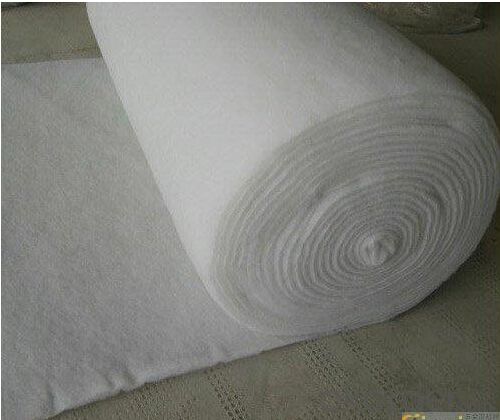

5. Some Photos of Continuous Filament Spunbond Needle Punched Polypropylene or Polyester Geotextiles for Construction Use

6. RFQ

1) What's your payment terms?

T/T or L/C at sight

2) What's your delivery time?

Within 15days against deposit received or original LC received

3) What's your pacakge?

Per roll with one woven bag

- Q: Can geotextiles be used in pond liner systems?

- Yes, geotextiles can be used in pond liner systems. Geotextiles are often employed as a protective layer or underlayment for pond liners to enhance their performance and prevent punctures or damage. They can help with drainage, filtration, and soil stability, making them a valuable component in pond liner systems.

- Q: How do geotextiles improve the performance of geotubes?

- Geotextiles improve the performance of geotubes by providing reinforcement and filtration. They act as a barrier to prevent the loss of soil particles while allowing water to pass through, thereby enhancing the stability and strength of geotubes. Additionally, geotextiles help distribute loads evenly, reducing the risk of erosion and increasing the overall performance and longevity of geotubes.

- Q: Roof of the geotextile

- Garage, roof green Huazhi geotextile manufacturers, solutions

- Q: How do geotextiles affect soil properties?

- Geotextiles can have various effects on soil properties. They can enhance soil stability and prevent erosion by acting as a barrier against soil movement and water flow. Geotextiles can also improve soil filtration and drainage by allowing water to pass through while retaining soil particles. Additionally, they can provide reinforcement to the soil, increasing its load-bearing capacity and reducing settlement. Overall, geotextiles can significantly influence soil properties, improving its performance and durability in various geotechnical applications.

- Q: PET geotextile is what?

- PET for the polyester on behalf of the name, PET geotextile is also divided into many kinds, such as: broken geotextile, filament geotextile, filament weaving, etc., I understand only these. Look at what you mean.

- Q: What kind of geotextiles are used to filter the geotextile?

- GBT-1998 geosynthetics staple fiber acupuncture non-woven geotextile GBT-1998 geosynthetics filament spunbond acupuncture non-woven geotextile

- Q: How do geotextiles help with load transfer in foundation systems?

- Geotextiles help with load transfer in foundation systems by providing a stable and strong layer of reinforcement. They distribute the load from the structure evenly to the underlying soil, preventing differential settlement and improving overall stability. Additionally, geotextiles can enhance the bearing capacity of weak soils and minimize the potential for erosion, thus increasing the longevity and performance of the foundation system.

- Q: How are geotextiles used in agricultural applications?

- Geotextiles are used in agricultural applications to control soil erosion, improve water drainage, and provide stabilization for slopes. They are often placed under roads, walkways, and erosion-prone areas to prevent soil erosion and maintain the integrity of the land. Additionally, geotextiles can act as a filter to separate fine particles from larger ones, allowing for better water drainage and preventing clogging in drainage systems. Overall, geotextiles play a crucial role in enhancing agricultural practices and preserving the health of the soil.

- Q: What are the standards and regulations governing geotextiles?

- The standards and regulations governing geotextiles vary depending on the country and its specific requirements. However, some common standards and regulations followed globally include those set by the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM). These standards typically cover aspects such as geotextile materials, design guidelines, testing methods, and performance requirements. Additionally, specific regulations related to geotextiles may exist at the national or regional level to ensure their proper use and compliance with environmental and safety standards.

1. Manufacturer Overview

| Location | 示范:Hebei, China |

| Year Established | 示范:1997 |

| Annual Output Value | 示范:Above US$50 Million |

| Main Markets | 30.00% South America; 20.00% North America; 15.00% Eastern Europe; 15.00% Southeast Asia; 10.00% South Asia; 5.00% Southern Europe; 5.00% Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin;Qingdao;Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 12 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

Geotextile Bricoman - Continuous Filament Spunbond Needle Punched Polypropylene or Polyester Geotextiles

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 120000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords