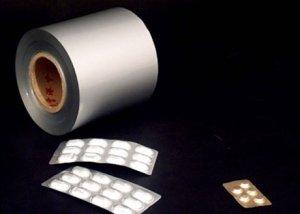

Aluminum Foil Feet Container Alufoil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium foil acts as a total barrier to light and oxygen (which cause fats to oxidise or become rancid), odours and flavours, moistness, and germs, it is used broadly in food and pharmaceutical packaging. The purpose of aluminium is to make long-life packs (aseptic processing|aseptic packaging) for drinks and dairy goods, which allows storing without refrigeration. Aluminium foil containers and trays are used to bake pies and to pack takeaway meals, ready snacks and long life pet foods.

Aluminium foil is widely sold into the consumer market, often in rolls of 500 mm (20 in) width and several metres in length.It is used for wrapping food in order to preserve it, for example, when storing leftover food in a refrigerator (where it serves the additional purpose of preventing odour exchange), when taking sandwiches on a journey, or when selling some kinds of take-away or fast food. Tex-Mex restaurants in the United States, for example, typically provide take-away burritos wrapped in aluminium foil.

Aluminium foils thicker than 25 µm (1 mil) are impermeable to oxygen and water. Foils thinner than this become slightly permeable due to minute pinholes caused by the production process.

Aluminium foil has a shiny side and a matte side. The shiny side is produced when the aluminium is rolled during the final pass. It is difficult to produce rollers with a gap fine enough to cope with the foil gauge, therefore, for the final pass, two sheets are rolled at the same time, doubling the thickness of the gauge at entry to the rollers. When the sheets are later separated, the inside surface is dull, and the outside surface is shiny. This difference in the finish has led to the perception that favouring a side has an effect when cooking. While many believe that the different properties keep heat out when wrapped with the shiny finish facing out, and keep heat in with the shiny finish facing inwards, the actual difference is imperceptible without instrumentation.The reflectivity of bright aluminium foil is 88% while dull embossed foil is about 80%.

- Q: Its a question that I don't getSomeoneplease help me understandChemistry quiz tomorow.

- Electronegativity is a chemical property that describes the tendency of an atom or a functional group to attract electrons towards itself.Boron will have a tendency to retain more negative charge than does aluminium, Therefore boron is more electronegative than aluminium.

- Q: i want the 13 inch aluminum macbookbut im on a budget! when do you think it will be available in the refurbished section? thanksslt;3

- I feed my cats Science Diet Weight Management dry foodI don't know if it's the healthiest of all the foods out there,but it was recommended by my vet,so that's what I useAs for the healthiest wet food,I don't feed my cats wet food,so I'm not sure of that one.

- Q: PLEASE THIS IS FOR A TEST I NEED IT OR IM GOIN TO FAIL

- The 2013 v6 is great as long as you can afford the gasBut to be honest being the v6 its not gonna be as much of a gas chuggerThe interior is pretty good but nothing super fantastic and my sound system is AWSOME to say the leastPerformance is also good even being a v6 is still a quick car and my hasnt had any problems yet and I drive it like a jet fighter so its very reliableYeah mustang over accord ANYDAY

- Q: I'm looking at buying 5 square cake tins - 4inches, 6, 8, 10 and 12All are 3quot; deep and made of aluminiumIs ?36 inc postage a good price? Thanks :)

- My mom uses Red Heart brand sometimesIt really depends on the color and gauge of yarn that she wants.

- Q: Where can I recycle aluminum cans for cash on east side of Cincinnati, Ohio?

- Try Round Bottom Recycling off Round Bottom Rd in MilfordTheir phone number is 248-335They were paying 75c a pound for cans a couple of weeks ago.

- Q: I'm currently in the process of having a dog crate built/welded out of aluminum round bar, angle iron, and square tubingI needed a heavy duty cage because I have a Blue Pitbull/American Bulldog Mix who has separation anxiety and has managed to break and bend one of these ASPCA crates founat Petco/Petsmart type stores to the point where it can no longer contain himThe only crates I can find online that would hold him costs between $800-$1000 so I calculated that I can have one built for about 1/4-1/3 that price.I was going to use standard aluminum floor plate for the bottom inside the cage but it seems like this would be cold, hard, and uncomfortableSince he manages to tear up any bedding or blankets I put in there for him I need something soft enough for comfort but strong enough so he cannot rip it up.Anyone know of any type of material I can use for this?

- I'm all for crate training dogs, and I crate all of mine at night, but if your dog is that distressed at being crated, he's obviously got problems that need to be addressed - either working with him to allay his fears, or giving him some sort of medication that your vet prescribesCrating a dog like that is just going to make him more insecure and nervous, you need to work to help him get over this issue, not just make it worse by forcing him into a stronger crateHe'll kill himself if he's as bad as you say, you can't just ignore the problem and keep him crated.

- Q: I know you have to order the aluminum and weld it but how do you bent it to be the shape of the frame, where do you order it from, how thick of aluminum do you need, and what are the nessasarry tools?

- There should be aluminum boat kits on the market to buy

- Q: just wanna know

- The glass tubes with a cork are generally the most airtight Aluminum/metal tubes are iffy

- Q: because me frnd just bought a hookah thing and i was wondering how do you smoke it?Do you inhale it? I know about the flavors and

- She is ungrateful and being that old, she is set in her waystake back what you gave her and give her junk back, go find some old newspaper etcyou dont need that stress.

Send your message to us

Aluminum Foil Feet Container Alufoil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords