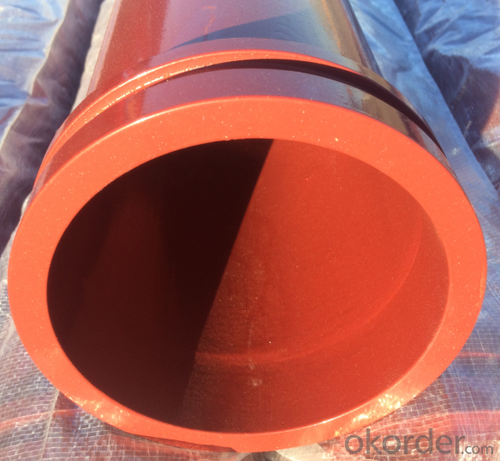

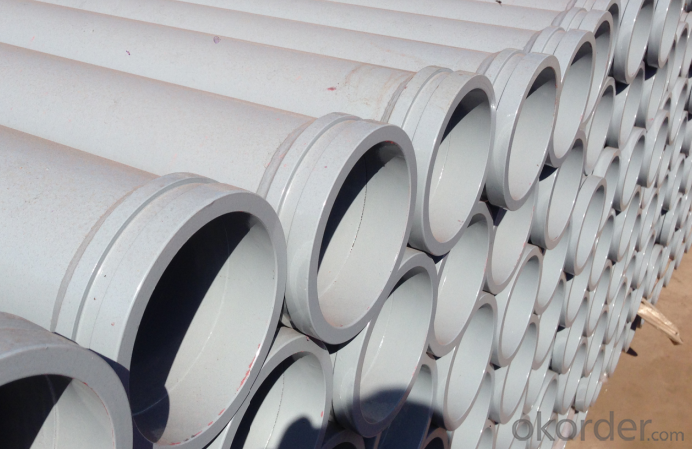

Concrete Pump Truck Parts Delivery Pipe without flange DN125 6MTR Thick 4.1MM ST52

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump pipes have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc.

Main Product Features:

1. Mainly adopt carbon steel high wear resistant steel, and other material upon your request.

2. Service life:7000-80000 CBM Concrete.

3. Possess quality certification of ISO 9001:2000. Can pass CE test.

4. We have been providing parts for nearly ten years, and cooperating with the agent of the world famous brand, possess near every kind of pipe in the market.

5. We can supply OEM service and can also produce according to your requirements./ OEM service available.

6. Total series of concrete pump pipes for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc) available from us.

Product Specifications:

Dimension: DN125

Length: 6m

Thickness: 4.1mm

Material: ST52

Weight: 83kg

Characteristics: double-ends flange

Package: Seaworthy packing or as customers’ request.

FAQ:

Q1: How to confirm that your pipes could be used in our pump?

A1: We have been providing parts for nearly ten years, and cooperating with the agent of the world famous brand, possess near every kind of pipe in the market. What is more, we can produce as the customers’ request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 5-15 workdays.

Q4: If we can produce some Concrete Pump Truck Parts according to customers request?

A4: Yes, we can produce Concrete Pump Truck Parts according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Other Products :

- Q: What are the layout requirements of concrete pump for building engineering?

- The setting of concrete pump should be steady and firm, with heavy vehicle running condition

- Q: What is the purpose of a concrete pump hopper agitator motor?

- The purpose of a concrete pump hopper agitator motor is to ensure the smooth and consistent flow of concrete within the hopper. The agitator motor is responsible for mixing and agitating the concrete mixture, preventing it from settling or becoming too thick. This motor helps to keep the concrete in a fluid state, ensuring that it can be easily pumped and distributed through the delivery system. Without the agitator motor, the concrete mixture may become stiff, leading to blockages and delays in the pumping process. Overall, the purpose of the concrete pump hopper agitator motor is to maintain the quality and efficiency of concrete pumping operations by keeping the mixture well-mixed and flowing smoothly.

- Q: How often should wear rings be replaced in a concrete pump?

- The frequency at which wear rings should be replaced in a concrete pump depends on several factors including the type of pump, the quality of the wear rings, the volume of concrete being pumped, and the operating conditions. In general, wear rings are components that experience significant wear and tear due to the abrasive nature of concrete. As a result, they will eventually need to be replaced to maintain the pump's efficiency and prevent potential damage to other parts of the pump. Typically, wear rings should be inspected regularly during routine maintenance checks. The wear patterns and extent of damage will determine whether replacement is necessary. In some cases, wear rings may last for several thousand hours of operation, while in others, replacement may be required more frequently. It is recommended to consult the pump manufacturer for specific guidelines on wear ring replacement intervals based on the pump model and operating conditions. They may provide recommendations based on their expertise and knowledge of the pump's design and performance. Ultimately, the goal is to ensure that the concrete pump operates smoothly and efficiently, minimizing downtime and maximizing its lifespan. Regular inspections and proactive replacement of wear rings when necessary will help achieve this objective.

- Q: How do I properly maintain and replace hydraulic motors in concrete pump spare parts?

- Proper maintenance and replacement of hydraulic motors in concrete pump spare parts is crucial to ensure the smooth operation and longevity of the equipment. Here are some steps to guide you in maintaining and replacing hydraulic motors effectively: 1. Regular Inspection: Perform routine inspections of the hydraulic motors to identify any signs of wear, damage, or leaks. Check the fluid levels and ensure they are at the recommended levels. 2. Cleanliness: Keep the hydraulic motors clean by removing any dirt, debris, or contaminants. This helps prevent the motors from overheating and minimizes the risk of damage to the internal components. 3. Fluid Maintenance: Regularly check and change the hydraulic fluid according to the manufacturer's recommendations. Clean and replace the filters to ensure the fluid is free from any particles that can cause damage to the motors. 4. Lubrication: Lubricate the hydraulic motors as per the manufacturer's instructions. This helps reduce friction and wear on moving parts, improving the overall performance and lifespan of the motors. 5. Proper Usage: Operate the concrete pump within the recommended load and pressure limits specified by the manufacturer. Overloading or excessive pressure can cause stress on the hydraulic motors, leading to premature failure. 6. Timely Replacement: Keep track of the service life and usage of the hydraulic motors. Over time, these motors may wear out and become less efficient. Replace them promptly when necessary to prevent any disruption to the concrete pumping operations. 7. Seek Professional Assistance: If you are unsure about maintaining or replacing hydraulic motors, it is advisable to seek professional assistance. They have the expertise and knowledge to carry out the necessary tasks correctly, ensuring the safety and optimal performance of the concrete pump spare parts. By following these steps, you can properly maintain and replace hydraulic motors in concrete pump spare parts, ensuring the longevity and efficiency of your equipment.

- Q: Why would the plugging concrete pump pipe

- When pumping, the operator shall observe the leftover material in the hopper at any time. The remaining material shall not be lower than the stirring shaft. If there is too little material, the air will be easily inhaled, which will lead to pipe blockage. The material in the hopper can not be piled too much, should be lower than the guard bar, so as to clean up the coarse aggregate and super large aggregate in time

- Q: How long do concrete pump hoses typically last?

- The lifespan of concrete pump hoses usually ranges from 5 to 10 years, contingent upon factors like usage, maintenance, and the hose's quality. Over time, the hose can deteriorate due to typical wear and tear, exposure to harsh chemicals, and extreme weather conditions. To prolong the hose's life, it is crucial to perform proper upkeep such as regular cleaning, inspection, and replacement of worn-out components. Nonetheless, it is essential to emphasize the significance of regularly monitoring and replacing hoses to guarantee the safety and effectiveness of the concrete pumping process.

- Q: Are there any specific safety precautions while replacing concrete pump spare parts?

- Yes, there are several safety precautions to consider while replacing concrete pump spare parts. Firstly, it is important to wear personal protective equipment such as gloves, safety glasses, and a dust mask to protect against potential hazards. Additionally, one should ensure the pump is turned off and disconnected from the power source before attempting any repairs. It is also crucial to follow proper lifting techniques and use appropriate tools to avoid injuries. Lastly, it is advisable to have a clear understanding of the equipment and its components, and if unsure, consult with a professional or refer to the manufacturer's guidelines for safe replacement procedures.

- Q: How can one source reliable suppliers for concrete pump spare parts?

- One can source reliable suppliers for concrete pump spare parts by following a few steps. Firstly, it is important to conduct thorough research on potential suppliers. This can be done by searching online directories, industry forums, and marketplaces dedicated to construction equipment and spare parts. Reading customer reviews and ratings can provide valuable insights into the reliability and quality of the suppliers. Secondly, it is advisable to reach out to industry professionals and experts who have experience in the concrete pump industry. They can provide recommendations and references for reliable suppliers they have worked with in the past. Additionally, attending trade shows and exhibitions related to the construction industry can be a great way to connect with suppliers and evaluate their product offerings in person. This allows for direct communication and the opportunity to assess the reliability and quality of their spare parts. Moreover, it is essential to request samples or product catalogs from potential suppliers to ensure that the spare parts meet the required specifications and quality standards. This can help in assessing the reliability of the suppliers and the compatibility of their products with the concrete pump. Furthermore, conducting background checks on the suppliers is crucial. Verifying their credentials, certifications, and licenses can provide assurance of their reliability and professionalism. It is also beneficial to inquire about their manufacturing processes and quality control measures to ensure the consistency and durability of the spare parts. Lastly, comparing prices, warranties, and after-sales services offered by different suppliers can help in making an informed decision. It is important to strike a balance between the cost and the reliability of the suppliers to ensure a long-term and fruitful partnership. By following these steps and taking the time to thoroughly evaluate and research potential suppliers, one can source reliable suppliers for concrete pump spare parts and ensure the smooth operation and maintenance of their equipment.

- Q: How can a faulty oil cooler affect the pump's hydraulic system?

- A faulty oil cooler can affect the pump's hydraulic system by causing the hydraulic fluid to overheat. When the oil cooler fails to properly cool down the hydraulic fluid, it can lead to an increase in temperature within the system. This can result in a decrease in the hydraulic fluid's viscosity, leading to reduced lubrication and increased wear and tear on the pump's components. Additionally, overheated hydraulic fluid can also lead to the degradation of seals and O-rings, causing leaks and further damage to the pump.

- Q: Can I get spare parts for concrete pump accessories like remote control systems?

- Yes, spare parts for concrete pump accessories like remote control systems are available. You can find them from various suppliers and manufacturers that specialize in concrete pump accessories.

Send your message to us

Concrete Pump Truck Parts Delivery Pipe without flange DN125 6MTR Thick 4.1MM ST52

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords