Color coated steel coils white color,green color,red color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

colour coated steel

painting colour steel , zinc coated steel , lead coated steel

Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | DX51D,SGCC,SPCC,CGCC | Thickness: | 0.17-1.5mm |

Place of Origin: | Taian China (Mainland) | Brand Name: | HengJi | Model Number: | HJ |

Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | RAL color cremated, oiled, skin passed |

Application: |

building metal roofing components,house appliance | Width: | 914-1250mm | Length: | customized |

price: | favorable price | Our Customers | Steel force, Stemcor, Duferco, Samsung , G&G,Hyosun |

Packaging & Delivery

Packaging Detail: | standard export packing or customized |

Delivery Detail: | 15 days after prepayment |

Specifications:

galvanized steel coil:

1.Thickness:0.17mm-1.5mm

2.Zinc coated:40g-275g/2

3.Standard:dx51d+z,sgcc

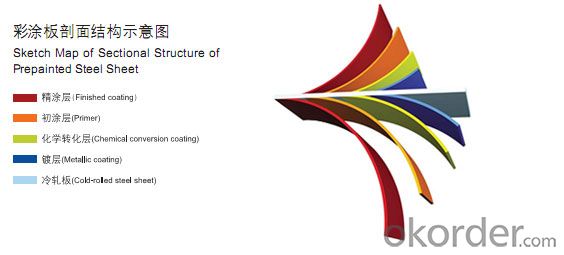

We manufacture Galvanized Steel Coils,Pre-painted Galvanized Steel Coils , etc

Prepainted steel coil features:

1. Zinc coating :40-120g(as reauired)

2. thickness:0.17-1.2mm

3. width:914-1250mm(900mm,1215mm,1250mm,1000mm the most common)

4. coil id:508m610mm

5. coil weight: 3-12(as required)

6. surface treatment:RAL color

Galvanized steel coil features:

1. Zinc coating :40-275g( as required)

2. thickness:0.17-1.2mm

3. width:914-1250mm(900mm,1215mm,1250mm,1000mm the most common)

4. coil id:508m610mm

5. coil weight: 3-12(as required)

6. surface treatment: cremated, oiled, skin passed

7. Spangle: regular,small, zero

8.Application: With excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils and widely applied in construction, home appliances, decoration, ect.

Product name | steel coil,galvanized steel,galvanized steel coil |

Material | DX51D, SGCC, SPCC, CGCC, DX51D |

Normal thickness | 0.17-1.2mm |

Normal width | 900mm,914mm, 1000mm, 1200mm, 1220mm, 1250mm |

Coil weight | 3-12ns |

Certificate | BV & SGS |

Original | Shandong,China |

Payment terms | L/C or T/T |

Delivery time | within 15 ~ 25 days after 30% prepayment |

- Q: How are steel strips used in the production of metal furniture?

- Due to their adaptable properties and long-lasting nature, steel strips are extensively utilized in the manufacturing of metal furniture. These strips are typically composed of top-notch steel alloys and are available in a range of widths and thicknesses. During the manufacturing process, steel strips are commonly cut to the desired length and then shaped into the necessary forms using techniques such as bending, rolling, or stamping. These strips serve as the main structural component, granting strength and stability to the furniture item. Steel strips are frequently employed in constructing the frames, legs, and supports of metal furniture items such as chairs, tables, shelving units, and cabinets. To create a sturdy structure capable of enduring heavy loads and daily usage, the strips are often welded or joined together. Moreover, steel strips have the ability to function as decorative elements in metal furniture. They can be bent or molded into intricate patterns and designs, enhancing the aesthetic appeal of the final product. These decorative strips can be affixed to the furniture surface or utilized as accents, elevating the overall appearance. Furthermore, steel strips are renowned for their resistance to corrosion, making them suitable for both indoor and outdoor applications. They can withstand exposure to moisture, humidity, and other environmental factors, guaranteeing the longevity of the metal furniture. In conclusion, steel strips play a vital role in the production of metal furniture by providing structural support, durability, and decorative elements. Their versatility and strength make them an ideal choice for manufacturing high-quality and long-lasting furniture pieces.

- Q: How do steel strips handle exposure to chemicals?

- Steel strips generally have good resistance to a wide range of chemicals, depending on the specific type of steel and the chemicals involved. However, certain aggressive chemicals can cause corrosion or other damage to steel strips over time. It is important to consider the specific chemical environment and consult with experts to ensure proper selection of steel grades and appropriate protective measures for handling exposure to chemicals.

- Q: How are steel strips packaged and shipped?

- Steel strips are typically packaged and shipped in coils or bundles. The strips are wound into tight coils and secured with steel bands or straps to ensure stability during transportation. These coils are then loaded onto pallets or into crates for added protection. Depending on the size and quantity, they can be shipped by truck, train, or container ship to their destination.

- Q: What are the factors that affect the magnetic properties of steel strips?

- The magnetic properties of steel strips can be influenced by several factors. Firstly, the composition of the steel plays a crucial role. Different elements added to the steel alloy can affect its magnetic properties. For instance, the addition of elements like nickel, manganese, and chromium can enhance the magnetic properties of steel strips. Secondly, the microstructure of the steel also has a significant impact on its magnetic properties. The crystal structure and grain size of the steel strips can determine their magnetic behavior. Steel with a fine-grained microstructure tends to have higher magnetic permeability and better magnetic properties. Thirdly, the processing and manufacturing techniques used for the steel strips can affect their magnetic properties. Factors like temperature, cooling rate, and annealing processes can influence the magnetic behavior of the strips. Improper processing or fabrication techniques can lead to the formation of non-magnetic regions within the steel, reducing its overall magnetic properties. Another factor that affects the magnetic properties of steel strips is their thickness. Thinner strips tend to have higher magnetic permeability due to reduced eddy current losses. Therefore, the thickness of the steel strips can be optimized to achieve desired magnetic properties for specific applications. Lastly, external factors such as temperature and mechanical stress can also impact the magnetic properties of steel strips. High temperatures can cause the loss of magnetic properties, while mechanical stress can alter the microstructure and affect the overall magnetic behavior of the strips. In conclusion, the magnetic properties of steel strips are determined by factors such as composition, microstructure, processing techniques, thickness, and external conditions. Understanding and controlling these factors are essential for designing steel strips with desired magnetic properties for various applications.

- Q: How are steel strips used in the production of metal furniture hardware?

- Steel strips are commonly used in the production of metal furniture hardware to provide structural support and reinforcement. These strips are often bent, cut, or shaped to form various components such as brackets, hinges, and handles. The strength and durability of steel make it an ideal material for ensuring the stability and longevity of metal furniture pieces.

- Q: What are the protective coating options for steel strips?

- To enhance the durability and longevity of steel strips, there are various protective coating options available. Some commonly used options are: 1. Galvanizing: The most widely employed protective coating method for steel strips is galvanizing. This involves the application of a zinc layer onto the steel surface through hot-dip galvanization. This coating provides excellent resistance against corrosion and helps prevent rust formation. 2. Powder Coating: Powder coating entails the application of a dry powder onto the steel strip surface, followed by curing it using heat. The powder adheres to the steel, forming a protective layer that is highly resistant to chipping, scratching, and fading. It also offers good corrosion resistance. 3. Epoxy Coating: Epoxy coatings are highly durable and resistant to chemicals, abrasion, and moisture. They are commonly used in industrial settings where steel strips are subjected to harsh conditions. Epoxy coatings can be applied as primers or topcoats, providing exceptional protection against corrosion and extending the lifespan of the steel strips. 4. Paint Coating: Painting is a cost-effective and frequently employed option for protecting steel strips. Various types of paint, such as acrylic, enamel, and polyurethane, can be used. The paint forms a barrier on the steel surface, preventing direct contact with moisture and reducing the risk of corrosion. 5. Organic Coatings: Organic coatings, such as polyvinylidene fluoride (PVDF) or polyester, are commonly utilized in architectural applications. These coatings offer excellent weather resistance, UV protection, and color retention. They are primarily used for aesthetic purposes and can be applied in a wide range of colors. When selecting a protective coating for steel strips, it is crucial to consider factors such as the intended application, environmental conditions, and budget. Seeking guidance from coating specialists or manufacturers can help determine the most suitable option for specific requirements.

- Q: How are steel strips used in the defense sector?

- Steel strips are used in the defense sector for various applications such as manufacturing armored vehicles, aircraft carriers, submarines, and military tanks. These strips are utilized to reinforce structures, provide protective shielding, and enhance the overall strength and durability of defense equipment.

- Q: What is the typical machinability of steel strips?

- The typical machinability of steel strips is considered to be good, as steel is a widely used material in various industries and can be easily machined using different cutting tools and techniques.

- Q: What are the different surface buffing methods for steel strips?

- There are several different surface buffing methods for steel strips, including mechanical buffing, chemical buffing, and electrochemical buffing. Mechanical buffing involves using abrasive pads or wheels to remove surface imperfections and create a smooth finish. Chemical buffing uses chemical compounds to remove oxidation or stains from the steel surface. Electrochemical buffing utilizes an electrical current to remove surface contaminants and create a polished finish. Each method has its own advantages and is chosen based on the desired outcome and the specific requirements of the steel strip.

- Q: How do steel strips perform in terms of electromagnetic shielding?

- Steel strips are highly effective in terms of electromagnetic shielding. Due to their conductive properties, they can efficiently block and divert electromagnetic waves, providing excellent protection against interference and reducing electromagnetic radiation.

Send your message to us

Color coated steel coils white color,green color,red color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords