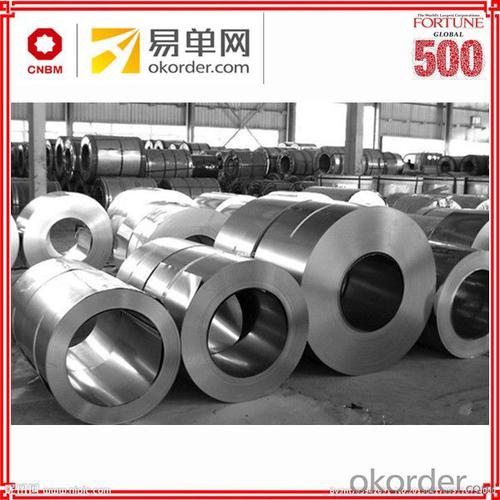

Cold steel coil building material prices china

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 54223 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Cold rolled sheet products have been available for many, many years, and have been successfully used for a multitude of

applications. Today's cold rolled sheet products are much improved over those used in the past. They offer better control of

thickness, shape, width, surface finish, and other special quality features that compliment the emerging need for highly

engineered end use applications.

Standard and Grade :

Cold rolled steel coils | ||||

JIS G3141-2005 | EN10130-2006 | ASTM A1008-12a | ||

Commercial quality | SPCC | DC01 | CS Type A/B/C | |

Drawing quality | SPCD | DC03 | DS Type A/B | |

Deep drawing quality | SPCE SPCF(non aging) | DC04 | DDS | |

Extra deep drawing quality | SPCG(non aging) | DC05/06 | EDDS | |

Application :

Automobile Industry, White Goods, Home Applicances, Oil & Air filters, semi product for coating with enamel or zinc, construction &

building sector, air-conditioning, furniture, radiators, tubes, profiles, mechanical construction, shelving, containers, drums

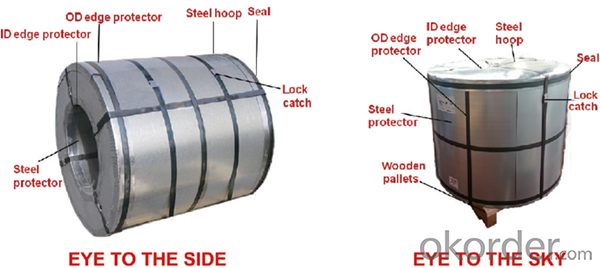

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Services:

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. Can you offer OEM to me? What about MOQ?

Of course, we are a professional with OEM manufacturer for 9 years. the MOQ can be 50 ton/ order.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we

have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will

provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing

as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

4.How Can I Get Some Sample?

We are honored to offer you free sample, but courier charges will be on your side.

- Q: What is the shear modulus of steel and silver? Please help! and state where you got it from...what site did you used? Thanks.

- There are more than 10,000 different steel alloys that have been specified and used for different purposes. They cover a huge range of mechanical properties. For silver, are you talking about pure silver, or a silver alloy with a additives to improve its mechanical properties? Typical values for mild steel at room temperature are E = 210 GPa, G = 80 GPa (source: 30 years working as a mech. engineer) Wikipedia gives E = 80GPa, G = 30GPa for pure silver (temperature not specified). Silver alloys may be very different from those values. The properties will also depend on the metal forming process (e.g. drawn wire, annealed, etc). NB some alloys with silver in their common name contain no silver at all.

- Q: What are the different methods of recoiling steel coils?

- Depending on the specific requirements and characteristics of the material, there are several methods employed for recoiling steel coils. Some commonly used techniques include: 1. Slitting: This method entails cutting the steel coil into narrower strips, which can then be recoiled. Rotary knives or circular saws are typically utilized in the slitting process, allowing for precise control over the width. 2. Rewinding: This approach involves unwinding the steel coil and subsequently rewinding it onto a new coil mandrel. It is commonly employed when resizing the original coil is necessary or when reconditioning a damaged coil. 3. Recoiling with a tension control system: This method passes the steel coil through a series of tension control rollers that apply a controlled amount of tension to the material. Consequently, the recoiling process is smooth and even, minimizing the risk of coil distortion or damage. 4. Recoiling with a slitter head: Combining the slitting and recoiling processes, this method employs a slitter head to simultaneously cut the steel coil into narrower strips and rewind them onto separate coils. 5. Recoiling with a looping pit: This technique involves feeding the steel coil through a looping pit, allowing for the accumulation of material as the coil is recoiled. This helps maintain a consistent line speed and tension throughout the recoiling process. Each of these methods possesses distinct advantages and is suitable for various applications. The choice of recoiling method depends on factors such as desired coil dimensions, material thickness and strength, and the required level of precision and quality.

- Q: How are steel coils processed at the steel service centers?

- Steel coils are processed at steel service centers through a series of steps to transform them into finished products that meet the specific requirements of customers. The process typically begins with the arrival of the steel coils at the service center. These coils are typically large and heavy, and may have been produced by a steel mill or imported from overseas. Once the steel coils are received, they are typically inspected for quality and any defects. This ensures that only high-quality coils are used in the production process. The coils are then stored in a warehouse until they are ready to be processed. Next, the steel coils are uncoiled. This involves unwinding the coil to create a flat sheet of steel. This can be done manually or using automated machines depending on the size and thickness of the coils. The uncoiled steel is then leveled to remove any residual stress and ensure a flat and consistent surface. After leveling, the steel sheets may undergo various processes depending on the desired end product. These processes can include cutting, shearing, slitting, and forming. Cutting and shearing involve cutting the steel sheets into specific sizes or shapes. Slitting involves cutting the steel into narrow strips, while forming involves bending or shaping the steel into the desired form. Once the desired processing operations are complete, the steel sheets are often treated with surface finishes to enhance their appearance or protect them from corrosion. These finishes can include painting, coating, or galvanizing. Finally, the processed steel sheets are inspected for quality again to ensure they meet the required specifications. They are then packaged and ready for shipment to customers, who may use them in various industries such as construction, automotive, or manufacturing. Overall, the processing of steel coils at steel service centers involves a combination of inspection, uncoiling, leveling, cutting/shearing/slitting/forming, surface finishing, quality control, and packaging. This process allows for the transformation of steel coils into finished products that are tailored to meet the specific needs and requirements of customers.

- Q: So i downloaded Broken Steel DLC for Fallout 3 for the 360. My guy is on the level where you have to activate the purifier and when i beat it. It was the normal ending that brought me back to the main menu. My friend said you have to find some guy to talk to but i don't think thats it. Please Help. P.S. i never got and conformation in-game about the download but its under the download sub menu at the main menu.

- after you've downloaded broken steel, while playing in game you should get a message saying, broken steel loaded, then you can make your way to the purifier and finish of the col. and activate it, after-wards you will have to sit through the end movie, which I felt was longer than the original, then the broken steel part will start, which I wont ruin. If your still having problems, go into your DLC and delete broken steel, and re-install it.

- Q: Can steel coils be transported by air?

- Yes, steel coils can be transported by air. However, it is important to note that the size and weight of the coils may limit the type of aircraft that can be used for transportation. Additionally, special equipment and packaging may be required to ensure the safe and secure transport of the coils.

- Q: i currently have just steel guitar strings, not a fan they need replacing and i was wondering whats the difference between steel and bronze strings and or nickle strings?

- Not all strings have a steel core. There are different substances used for the core on metal guitar strings (not even mentioning nylons), but the market is predominated by a steel core. The tonal properties of what steel strings are wound up by can make a great difference to the overall sound of an instrument. In general, nickel strings are bright but give off well-rounded frequencies and have properties that make them perfect for use with magnetic pickups, such as those used in electric guitars. Bronze-wound strings are a little mellower in timbre but give off more high-low (harmonically rich) frequencies and are favorites on acoustic steel-string guitars. Silk and steel-wound guitar strings are the mellowest sounding and give off more low-mid frequencies than the others. They are generally used for folky types of acoustic playing where little attack is needed. There are others but I won't mention them because you won't find them easily. There are other factors and merits of each type of string like how long they last - Nickel resists corrosion the most; bronze less so; bare steel oxidizes very easily. There is also the way the string is wound to take into account (flat-wound, etc. like the other answerer mentioned).

- Q: hey i was looking to buy a khukuri machete by cas iberia. its made of carbon steel but doesnt say which one. anyone that is into knives and all that know how this would hold up and the rust resistance of it? mostly be used for cutting bush and small trees

- There's no way to tell from the information you posted. Given it's for a machete I would guess it would be a fairly high carbon steel. Rust resistance will be relatively poor. It will last for years though as long as you clean and dry it after use.

- Q: How are steel coils protected against corrosion?

- Steel coils are protected against corrosion through various methods such as applying protective coatings like zinc, aluminum, or polymer, or using a process called galvanization where the coils are coated with a layer of zinc. Additionally, storing the coils in a controlled environment with low humidity and proper ventilation also helps prevent corrosion.

- Q: How are steel coils used in the production of automotive chassis?

- Steel coils are used in the production of automotive chassis as they provide the primary material for constructing the framework of the vehicle. These coils are first processed and shaped into the desired form, such as beams or plates, which are then welded together to form the chassis. The high strength and durability of steel make it an ideal choice for withstanding the stresses and loads experienced by the chassis, ensuring the safety and structural integrity of the vehicle.

- Q: What are the current trends in the steel coil industry?

- Some current trends in the steel coil industry include a growing demand for high-strength and lightweight steel coils, increased focus on sustainability and recyclability, advancements in technology for improved efficiency and productivity, and a shift towards automation and digitalization in manufacturing processes. Additionally, there is a rising preference for customized steel coil solutions to meet specific industry requirements.

Send your message to us

Cold steel coil building material prices china

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 54223 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords