Cold Rolled Plate Steel,Steel Coils Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

DESCRIPTION:

GRADE: SS400, ASTM A36, A572, ST37,ST52, Q195, Q215, Q235,Q345, S235JR etc.

STANDARD: GB/T709-2006, ASTM A36, JIS G3101, DIN EN 10025, SAE 1045, ASTM A570

SPEC:

1)Width: 600-2500mm or 1000,1050,1250,1500,1800,2000mm

2)Thickness:1.5mm-200mm or as customers’ special requirements;

3)Length: 2-12m or as customers’ special requirements

DETAILS:

Thickness | 0.5-100mm |

Width | 1250mm,1500mm,1800mm,2000mm.,2500mm or as required |

Length | 2000-12000mm |

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Material | A36,SS400,SPCC,SPHC, Q195, Q 235,Q345 |

Tehnique | Hot rolled;cold rolled |

Payment | TT ,L/C |

Packing | Standard seaworthy packing or as required |

Market | Mild east, North/South America, Europe, Asia,Africa etc |

Certificate | BV,SGS,MTC |

Delivery time | 30-45days after confirming the order |

PACKING:

1.Big thickness:by bulk vessel

2.Small thickness:packed by steel strips and shipped by container

3.According to the requirements of customers'

TRADE TERMS :FOB, CFR, CIF

PAYMENT&DELIVERY FOR STEEL COILS/SHEETS

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy |

Delivery Time | With 30-40 days after deposit |

Price Terms | Ex-Work, FOB, CNF, CFR, CIF,etc |

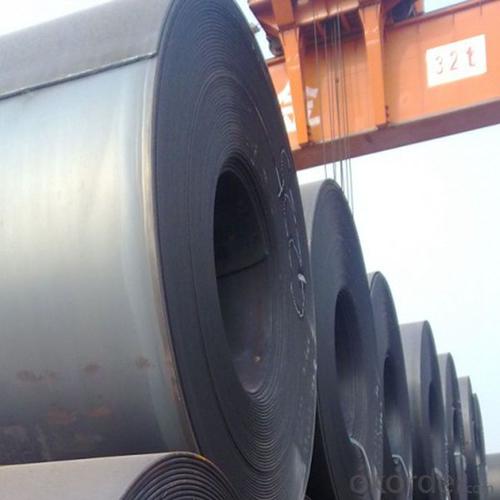

DETAILED PICTURES FOR STEEL COILS

FEATURES OF STEEL COILS

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

OUR SERVICE

1.High quanlity and reasonable price.

2.Customized on-demand.

3.Reasonable shipping and fast delivery.

4.Free sample.

FAQ

Q:What are the advantages of your company ?

A: We have many professionals, technical personnel, more competitive prices and best after-dales service than other steel companies.

Q:Can you arrange the shipment ?

A: Sure we can help you with the shipment. We have forwarders who have cooperated with us for many years.

- Q: How do steel sheets perform in high-humidity environments?

- Due to their inherent properties, steel sheets typically exhibit excellent performance in environments with high humidity. Steel is renowned for its strength, durability, and resistance to corrosion, rendering it a suitable material for enduring conditions characterized by excessive moisture. In certain materials, the presence of high humidity can result in the development of condensation on surfaces, thereby accelerating the corrosion process. However, steel sheets are often endowed with protective layers such as zinc or other corrosion-resistant coatings. These coatings function as a barrier against moisture, effectively preventing the onset of rust. Moreover, steel sheets are frequently subjected to galvanization or treatment with specialized coatings like stainless steel or weathering steel. These measures serve to enhance their resistance to humidity and forestall degradation over time. By providing an additional layer of protection, these coatings ensure that steel sheets retain their structural integrity and continue to perform well even in environments with high humidity. It is worth emphasizing that while steel naturally possesses resistance to moisture, the implementation of proper maintenance and care remains crucial to ensure its long-term performance. Regular inspections, cleaning, and the application of suitable sealants or coatings, if necessary, can further fortify steel sheets against the challenges of high humidity. In conclusion, steel sheets are generally well-suited for high-humidity environments due to their strength, durability, and corrosion resistance. Through the application of appropriate coatings and diligent upkeep, steel sheets can uphold their performance and structural integrity even in conditions characterized by an abundance of moisture.

- Q: Can steel sheets be used for walkways and platforms?

- Yes, steel sheets can be used for walkways and platforms. Steel sheets are durable, strong, and capable of supporting heavy loads, making them suitable for such applications. Additionally, they can be fabricated and designed to meet specific requirements, ensuring safety and stability for users.

- Q: What is the typical price range for steel sheets?

- The typical price range for steel sheets can vary depending on several factors such as the type and grade of steel, the thickness and size of the sheets, and the current market conditions. Generally, steel sheets can range in price from around $30 to $200 per sheet. However, it's important to note that these prices are approximate and can fluctuate significantly. It is always recommended to check with local suppliers or manufacturers to get the most accurate and up-to-date pricing information for steel sheets.

- Q: Can steel sheets be used for decorative column wraps?

- Yes, steel sheets can be used for decorative column wraps.

- Q: What is the process of embossing on steel sheets?

- The process of embossing on steel sheets involves creating raised or recessed designs on the surface of the steel. This technique is commonly used to add texture, improve aesthetics, or enhance the mechanical properties of the steel. The first step in the embossing process is preparing the steel sheets. This typically involves cleaning the surface to remove any dirt, oils, or coatings that may interfere with the embossing process. The steel sheets are then carefully inspected for any imperfections or surface defects that could affect the embossing quality. Once the steel sheets are prepared, they are placed in an embossing machine, which consists of two or more rollers. These rollers have engraved patterns on their surfaces, which will be transferred onto the steel sheets. The rollers are typically made of hardened steel or other materials that are resistant to wear and tear. As the steel sheets pass through the embossing machine, pressure is applied to the rollers, causing them to press against the steel surface. This pressure creates a plastic deformation in the sheet, resulting in the desired raised or recessed pattern. The depth and intensity of the embossing can be adjusted by controlling the pressure applied by the rollers. In some cases, heat may be applied during the embossing process to soften the steel sheets and make them more malleable. This allows for deeper and more intricate embossing patterns to be achieved. The temperature and duration of the heating process will depend on the specific type of steel being used and the desired outcome. After the embossing process is complete, the steel sheets may undergo additional treatments such as cleaning, coating, or polishing to further enhance their appearance and protect them from corrosion. These finishing steps help to ensure that the embossed steel sheets meet the desired quality standards and are ready for their intended application. Overall, the process of embossing on steel sheets is a versatile and effective way to add texture and visual interest to the surface of the steel. It requires careful preparation, precision machinery, and skilled operators to achieve consistent and high-quality results.

- Q: How do steel sheets compare to aluminum sheets in terms of weight?

- Steel sheets are generally heavier than aluminum sheets.

- Q: What is a water stop steel plate?

- The main application areas of water stop steel plate are tunnel, subway, dyke, culvert, water conservancy and hydropower project, construction joint, basement of high-rise building, underground parking lot, etc..

- Q: Can the steel sheets be easily welded?

- Yes, steel sheets can be easily welded. Welding is a common method used to join steel sheets together. The process involves melting the edges of the steel sheets and then allowing them to cool and solidify, creating a strong bond. However, it is important to note that the ease of welding can depend on the type and thickness of the steel sheets, as well as the skill and experience of the welder. Additionally, proper safety precautions and welding techniques should be followed to ensure a successful and safe welding process.

- Q: Are steel sheets easy to clean and maintain?

- Yes, steel sheets are easy to clean and maintain. They have a smooth surface that can be wiped clean with a damp cloth or cleaned using mild soap and water. Additionally, steel sheets are resistant to staining, rusting, and corrosion, making them low-maintenance and durable.

- Q: What are the applications of steel sheets in construction?

- Due to their exceptional strength, durability, and versatility, steel sheets find a wide range of applications in the construction industry. Some of the key uses of steel sheets in construction are: 1. Roofing and cladding: Steel sheets are commonly employed in both residential and commercial buildings for roofing and cladding purposes. They offer a long-lasting and weather-resistant solution, safeguarding the structure against the elements. 2. Structural components: Steel sheets are utilized to construct beams, columns, and trusses, which are essential structural components. The high strength-to-weight ratio of steel enables the creation of lightweight yet robust structures capable of withstanding heavy loads and seismic forces. 3. Flooring: In industrial buildings, warehouses, and factories, steel sheets are often used as flooring material. Their smooth surface facilitates easy cleaning and maintenance, and their strength and fire-resistant properties ensure a safe working environment. 4. Wall partitions: Steel sheets are commonly used in the construction of wall partitions due to their stability and sound insulation properties. They can be easily cut and shaped to fit any design, allowing for flexible and customizable partition layouts. 5. Ductwork and HVAC systems: Steel sheets find extensive use in the fabrication of ductwork and HVAC systems. Their smooth and airtight surfaces enable efficient air movement and regulation, ensuring proper ventilation and temperature control in buildings. 6. Reinforcement: Steel sheets are frequently integrated into concrete structures as reinforcement. This enhances the strength and load-bearing capacity of the building, making it more resistant to bending, tension, and compression forces. 7. Safety and security: Steel sheets are utilized in the construction of safety and security features such as doors, gates, and window frames. Their high strength and resistance to impact and vandalism make them an ideal choice for ensuring the safety and protection of a building. In conclusion, steel sheets play a crucial role in construction for various applications, including roofing, cladding, structural components, flooring, wall partitions, ductwork, reinforcement, and safety features. Their superior strength, durability, and versatility make them an indispensable component in different construction projects, contributing to the overall safety, longevity, and functionality of buildings.

Send your message to us

Cold Rolled Plate Steel,Steel Coils Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords