Cold Rolled Galvanized Steel Coil JIS G3302 EN10142 ASTM A653

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

DESCRIPTION FOR GALVANIZED STEEL COILS:

Mian Quality Standard | JIS G3302, EN10346, DIN17162, ASTM A653/653M, GB2518 |

Process | hot dip galvanizing |

Process Speed | 1#. Max 120m/min, 2#. Max 130m/min |

Thickness | 1#. 0.25mm upto 1.20mm, 2#. 0.25mm upto 1.0mm |

Width | 900mm upto 1300mm |

Surface Finish | zero spangles, skinpassed, oiled,chromated, tension level, |

Coating | zinc layer mass on both sides from 30 g/m2 upto 180g/m2 |

Yield Strength | 220Mpa upto 750Mpa |

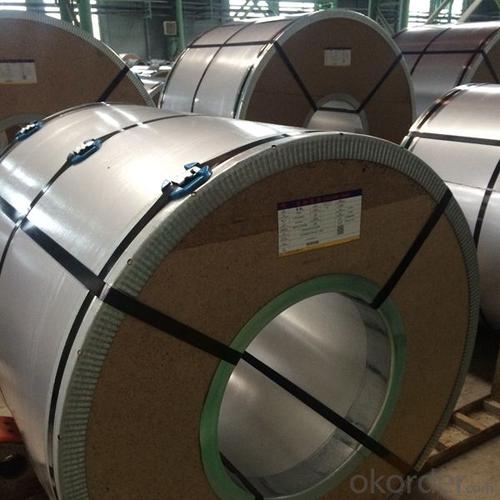

Weight per Coil | max 15,000kg |

Inner Diameter | φ 508mm |

Outer Diameter | max φ 2,050mm |

Finished Internal Diameter | Φ 508mm or φ 610mm |

Finished Coil Weight | 1#. max 10,000kg, 2#. max 15,000kg |

Packing | Mill's Export Standard Packing |

Capacity | 300,000 tons/year |

EXPORT STANDARD FOR GALVANIZED STEEL COILS:

-Axial and circumferential steel straps with seal (4 steel straps each)

-VCI Anti-rust kraft paper

-Water-proofing plastic

-Pearl wool (coil surface)

-Steel cover (coil surface/bore)

-Plastic cover (coil sides)

-Inside and outside corner protectors

Or According customers' requirements(Usually only for domestic)

PACKAGING &DELIVERY FOR GALVANIZED STEEL COILS:

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

PACKAGING &DELIVERY FOR GALVANIZED STEEL COILS:

1.Big thickness:by bulk vessel

2.Small thickness:packed by steel strips and shipped by container

3.According to the requirements of customers'

TRADE TERMS FOR GALVANIZED STEEL COILS:FOB, CFR, CIF

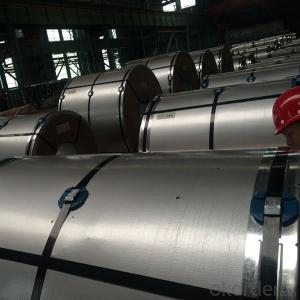

DETAILED PICTURES FOR GALVANIZED STEEL COILS:

APPLICATION FOR GALVANIZED STEEL COILS:

Galvanized steel products are mainly used in construction, light industry, automobile, agriculture , fishery and commercial industries. They have great advantages:1.it has small harm to the environment and it can be recycled, greatly lighten the stress to the environment.2.it is convenient to process,easy to construct and has good waterproof effect.

FAQ FOR GALVANIZED STEEL COILS:

Q:Do you have OEM service?

A: Yes.Variety of products size,quality and quantity can be customized according to your need.

Q:Could you support free sample?

A:Yes.We can supply FREE samples.But the delivery charges will be covered by our customers.

- Q: What are stainless steel sheets used for?

- Stainless steel sheets serve a multitude of purposes in diverse industries. Their outstanding resistance to corrosion, durability, and attractive appearance make them highly sought after in both commercial and residential settings. Within the construction field, these sheets are utilized for roofing, cladding, and facades due to their ability to withstand harsh environmental conditions while providing a contemporary and sleek look. In the automotive industry, they are frequently employed in the construction of car bodies, exhaust systems, and decorative trims. Furthermore, stainless steel sheets find extensive use in the food and beverage sector, where their hygienic qualities make them ideal for kitchen equipment, countertops, and food processing machinery. Additionally, they are widely used in medical equipment, pharmaceuticals, and laboratory settings due to their resistance to corrosion and ease of cleaning. They are also employed in furniture, appliances, signage, and for decorative purposes, as they can be easily customized and molded into various shapes and sizes. All in all, stainless steel sheets are an adaptable material that fulfills a diverse array of requirements in different industries, owing to their strength, durability, and corrosion resistance properties.

- Q: What type of welding rod is used for 304 stainless steel plate welding?

- 304 stainless steel is the United States brand, equivalent to the domestic brand 06Cr19Ni10, usually with A102 or A107 welding rod.

- Q: Can stainless steel sheets be used for hygienic applications?

- Stainless steel sheets are indeed suitable for hygienic applications. The reason lies in its remarkable hygiene properties attributed to the non-porous surface, which effectively resists bacteria, mold, and other microorganisms. Moreover, stainless steel is effortless to clean and maintain, making it perfect for sectors that prioritize cleanliness and hygiene, including the food and beverage industry, healthcare facilities, and pharmaceutical manufacturing. Furthermore, stainless steel exhibits exceptional durability, corrosion resistance, and high-temperature tolerance, rendering it a superb choice for hygienic applications.

- Q: What are the different types of stainless steel sheet finishes available?

- There are several different types of stainless steel sheet finishes available, each with its own unique characteristics and applications. Some of the most common finishes include: 1. No. 1 Finish: This is the most basic type of stainless steel sheet finish, also known as hot rolled or annealed and pickled finish. It has a rough, dull appearance with a non-reflective surface. It is commonly used in industrial applications where aesthetics are not a primary concern. 2. No. 2B Finish: This is a smooth, semi-reflective finish that is achieved by cold rolling, annealing, and pickling. It has a slightly glossy appearance and is commonly used for applications where a moderate level of corrosion resistance is required. 3. No. 4 Finish: This finish is achieved by polishing the stainless steel sheet with a fine abrasive material. It has a brushed appearance with a low gloss finish. It is often used in architectural and decorative applications, such as kitchen appliances, countertops, and elevator panels. 4. No. 8 Finish: Also known as a mirror finish, this is the most reflective stainless steel sheet finish available. It is achieved by polishing the surface with progressively finer grits until a mirror-like finish is achieved. It is commonly used in decorative applications, such as architectural accents, signage, and ornamental pieces. 5. Satin Finish: This finish has a smooth, satin-like appearance with a low to medium gloss level. It is achieved by using a combination of brushing and polishing techniques. It is often used in applications where a balance between aesthetics and functionality is desired, such as kitchen equipment, sanitary appliances, and automotive trim. 6. Bead Blasted Finish: This finish is achieved by blasting the surface of the stainless steel sheet with glass beads at high pressure. It creates a uniform, matte appearance with a subtle texture. It is commonly used in architectural and interior design applications, such as wall panels, elevator doors, and furniture. 7. Embossed Finish: This finish is achieved by imprinting a pattern onto the surface of the stainless steel sheet using a mechanical process. It creates a textured appearance that can range from subtle to dramatic, depending on the pattern. It is often used in decorative applications, such as wall cladding, signage, and decorative panels. These are just a few examples of the different types of stainless steel sheet finishes available. The choice of finish depends on the specific requirements of the application, including aesthetics, corrosion resistance, and functionality.

- Q: What are the different types of etched patterns available for stainless steel sheets?

- There are various types of etched patterns available for stainless steel sheets, including geometric designs, floral motifs, abstract patterns, textured surfaces, and custom designs.

- Q: Can stainless steel sheets be used for cryogenic applications?

- Yes, stainless steel sheets can be used for cryogenic applications. Stainless steel has excellent mechanical properties at low temperatures and provides good resistance to thermal shock and corrosion, making it suitable for cryogenic environments.

- Q: What are the different types of stainless steel sheet textures available?

- There are several types of stainless steel sheet textures available, including brushed, mirror, embossed, and patterned.

- Q: How do you determine the hardness of stainless steel sheets?

- The hardness of stainless steel sheets can be determined using various methods such as the Rockwell hardness test, Brinell hardness test, or Vickers hardness test. These tests involve applying a specific amount of force or pressure to the surface of the steel sheet and measuring the depth of indentation created. The hardness value obtained from these tests indicates the resistance of the stainless steel sheet to deformation or scratching, thus providing a measure of its hardness.

- Q: What are the common manufacturing standards for stainless steel sheets?

- The common manufacturing standards for stainless steel sheets include ASTM A240, ASME SA240, EN 10028-7, and JIS G4304. These standards specify the chemical composition, mechanical properties, tolerances, and surface finishes required for stainless steel sheets used in various industries.

- Q: Are stainless steel sheets suitable for industrial kitchens?

- Yes, stainless steel sheets are highly suitable for industrial kitchens. They are corrosion-resistant, durable, and easy to clean, making them ideal for the rigorous demands and high hygiene standards of industrial kitchen environments. Stainless steel sheets also have excellent heat resistance and can withstand heavy use, making them a reliable choice for commercial cooking areas.

Send your message to us

Cold Rolled Galvanized Steel Coil JIS G3302 EN10142 ASTM A653

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords