CNBM-030-Z3 Coating Filling Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

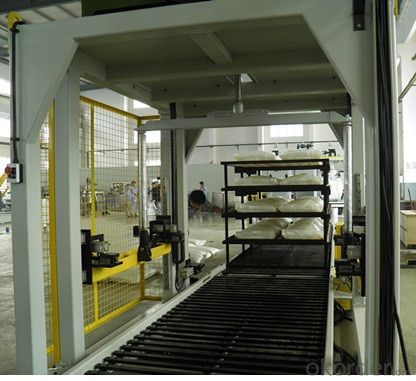

CNBM-030-Z3 Coating Filling Machine

I. Application and performance

Coating filling machine is applied to fill coating, paint, ink, lubricant, oil and so on, fine chemical, daily chemical, foodstuff material, pharmacy material, bitumen and so on.

II. Features

Coating filling machine is composed of SS roller conveyor, filling postion, feeding cap, capping, electrical control, pneumatic control and vacuum control. Manual feeds drum at inlet of conveyor, which is conveyed to feeding position, when sensor checks drum, weighing position stays to wait, pusher pushes drum to filling and weighing platform. The sensor checks drum, open filling nozzle and feeding valve automatically, fast filling to set value, feeding valve closes and slow filling, to set value, filling nozzle closes. After feeding cap, pusher pulls the drum to conveyor to feeding cap. When the sensor checks drum, stop it and catch cap rotate then put it on the drum, then to capping position. When capping sensor checks drum also stop it then cap it, after that, capping head resets, orientator releases it to be discharged out.

III. Technical parameter

| Name | ModelT. Data | CNBM-030-Z3 |

| Coating filling machine | Weighing range(kg) | 10-50 (others can customize) |

| Filling speed(tims/h) | 400-600 | |

| Accuracy | ±0.2% | |

| Outfit power | AC380V +10% -15% 50Hz±2Hz | |

| Outfit air | Flux 0.1m3/minPressure 0.4~0.6MPa | |

| Power KW | 4 | |

| Ambient temperature | 0℃~40℃ | |

| Overall dimension (mm) | As practical machine | |

| Weight (kg) | 1050 |

- Q: Where is secondhand corrugated paper packaging machinery available?

- Carton factory and general production enterprise is different,General business is to face direct consumers, the need for their own sales network, sales staff, sales means......And carton factory as long as accurate manufacturers, show their means, get business.Maybe you walked into a food factory, an electrical factory, a furniture factory, a toy factory...... Can be your client.With business, but also to choose their own plant.Cartons are flammable and afraid of water. This is the disadvantage of cartons. If handled properly, there will be no problem.Site is best to avoid low-lying and rainy lots of water, the cardboard should not be piled directly on the ground, the bracket is a good choice.No smoking in the factory area, no open fire, and good fire fighting equipment, so as to ensure the safety of production.The size of the initial plant is best to be 500 square meters, or larger, smaller.

- Q: What is the design basis of automated packaging?! Just for today!

- Greatly improve the degree of automation of process flowA few years ago, automation technology accounted for only 30% of the design of packaging machinery, now has accounted for more than 50%, a large number of micro computer design and mechanical and electrical integration control. To improve the packaging machinery automation, one is to increase productivity; the two is to improve the flexibility and agility equipment; three is to improve the ability of packaging machinery to complete the complex action, namely the manipulator to complete the packaging process. Such as chocolate packaging has been achieved, with mechanical hand instead of the original manual. Automatic design of packaging machinery has the following two main characteristics:

- Q: Ask a mechanical problem, the waste film recycling in the packaging machinery is a new film packaging, after cutting, then use the roller to recycle the waste film. Encounter a

- It is suggested that displacement or velocity should be detected on the transport path of the membrane. Is a more reliable control signal. Of course, you can also detect the angular speed of the recovery drum, such as a code dial and other simple institutions.

- Q: What is the price of a small jujube packing machine?

- What is the price of a small jujube packing machine?

- Q: What kind of reducer is commonly used in packaging machinery?

- There are many kinds of reducers used. What kind of machines are they under?

- Q: How much is the tableware wrapping machine?What's the price of the tableware wrapping machine?

- Tableware packaging machine packaging production, simple operation and high degree of automation, high efficiency, low packing cost, save labor, reduce the damage and the characteristics of two pollution, by tableware shrink packaging is widely used in all kinds of, is a very mature model

- Q: How is the production and characteristics of ceramic wall tiles different from the size and performance of molding?

- What is the production process of ceramic wall and floor tiles? What are the characteristics of the powders produced by spray drying?The tiles and other ceramic raw materials is similar to inorganic non-metallic materials (mainly silicate) as the main raw material, through accurate mixing processing, according to certain technology and shape the final firing. Significant features of the product shape are the rule of Fu Banzhuang, and most of the semi dry pressing method, and therefore suitable for automatic production line of raw materials 4 ingredients of crude, water, 4 fine granulation molding - burning glaze, glaze firing and assembly of I (paving) pick - packagingThere are different granulation methods in different production processes. The former is to dehydrate the mud and then dip it into the mud or directly with mud cake. The equipment has small investment, easy installation, operation and maintenance, irregular particle shape, uneven thickness and poor flowability. The I drying tower of the spray drying machine directly prepared the slurry into powder, which has high powder making efficiency and good powder flowability, and is the most ideal automatic powder powder making system at present. When the powder made from spray drying tower is pressed to wall and floor tile, the billet handle can be increased by about 30%.

- Q: Which friend is an expert in mechanical equipment or a better understanding of sealing machines? Tell me how to identify the equipment

- Take the food packaging machine for example, if only from the hardware, then you can ask when you buy the degree of automation, semi-automatic or fully automatic, the use of steel ah,

- Q: What are the structures of the packaging machinery?

- Is a company engaged in outsourcing clients, packaging, processing, packaging equipment, leasing, services, sales in one of the specialized companiesSales of second-hand packing equipment according to the customer's product features and requirements. Reduce customer purchasing costsAccording to the customer's product characteristics and requirements. Select the best packaging equipment for customers, reduce customer purchasing costsPackaging equipment spare parts sales and maintenance services

- Q: What are the packaging machines that use temperature control watches?

- Direct heating sealing machine, blister packing machine, plastic sealing machine, heating pot, oven, toaster and so on

Send your message to us

CNBM-030-Z3 Coating Filling Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords