CMAX High Output Conical Twin-screw Plastic Extruder For High-speed Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

conical twin-screw extruder for high speed profiles is successfully developed by our company according to the market and clients’ demands, Mainly used to produce PVC door & window profiles etc, mainly for supporting high-speed extrusion line, a mode double out production line or windowsill board extrusion line and so on. Such kind of extruder is welcomed by the users with high output, extrusion stability, low- energy consumption.

Advantage:

High flexibility through gentle, homogeneous plasticization

AC motors for low energy consumption

A choice of different screw geometries for processing customer-specific PVC compounds

Low maintenance screw and an air-cooled barrel

Powerful gearbox; robust and compact design

Excellent price-performance ratio

Packaging & Shipping:

Packaging: PE film wrapped around & wooden pallet or wooden case worthy for long distance sea and land transportation ;

Delivery: 30 working days after receiving down-payment.

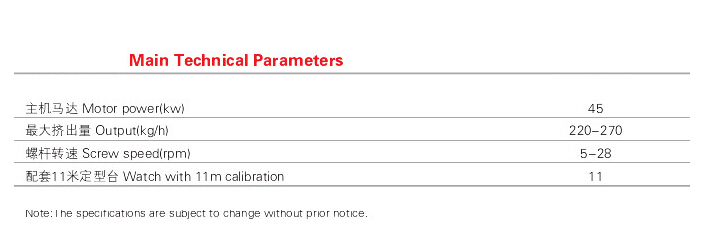

Technical Data:

Company Information

CNBM International Corporation

(CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.With the advantages in Cement, Composite Materials, New Building Materials and Engineering, We are enlarging sub-brand. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization. Meanwhile, we have established strategic partnerships with hundreds of domestic manufacturers and sound business relations with clients from over 120 countries. In line with the business, CNBM International launched E-business platform Okorder.com. It conformed the best resource and logistics to meet the customers’ request with 24 hours full-time service.

Our Vision: Initiate new global trading structure; create new value for benefit related partners.

We will do utmost to promote rational use of resources under the new structure, meanwhile, create new value of “green, environment friendly and sustainable’ for a more prosperous future.

CNBM International Co. Carpet Dept.

At CNBM International Co. Carpet Dept., we design and weave beautiful carpets of superb durability - with axminster, tufted and wilton carpets to suit all hospitality environments. · There is no size limitation on rug size. Rugs can be created with a variety of materials from pure wool to woolen silk, from natural fiber to chemical fiber.

- Q: For example, 70 square conductors, the outer diameter is A, out of the insulation, then the line mouth to choose how much, how much plastic cover election? Then the sheath, then how to choose the mold?

- Depending on your specific specifications, if XLPE is insulated, extrusion die with small touch line, set on the use of cable diameter, large core conductor than a few tenths of good, if you like to use 70 square tube extruding mold insulation of the conductor element some is big 1 can be set according to the touch, the tensile ratio calculation,

- Q: Basic parameters of extruder screw

- 2. The ratio of the length to diameter of the screw, the length of the screw L/Ds and the ratio of L to the diameter of the screw Ds is called the ratio of length to diameter. When the other conditions are constant (such as the diameter of the screw), increasing the ratio of length to diameter means increasing the length of the screw. The L/Ds value is large and the temperature distribution is reasonable, which is beneficial to the mixing and plasticizing of plastics. At the same time, the heating time of the plastic in the barrel is longer, and the plasticization of the plastic will be sufficient and more uniform. So as to improve the quality of machine plastics. If the plastic quality requirement is constant, the rotation speed of the screw can be increased after the ratio of length to diameter increases, thereby increasing the extrusion amount of the plastic. However, too large length diameter ratio, power consumption will increase the screw, and the screw and barrel of the processing and assembly of chicken more difficult; the possibility of screw bending will increase, will cause the abrasion of the screw and the inner wall of the cylinder, reduce the service life. In addition, the heat sensitive plastic, large diameter and long retention time than thermal decomposition, the plasticizing and impact plastic extrusion quality. Therefore, in the full use of the advantages of increasing the ratio of length to diameter, the selection should be based on the physical properties of the processed plastics and the quality requirements of the products.

- Q: Why is the connection between the extruder and the switchboard?. The upper and lower three terminals are short circuited

- The action should be to require three simultaneous electricalOr a two way backup

- Q: Produce 10 square wires with the smallest extruder

- If it is a production sheath line, do at least 70 machines, preferably 70 or 90 insulation, and 90/120 as sheath

- Q: What are the two types of extrusion?

- Extrusion? The extruder. The extruder is divided into single screw extruder and twin screw extruder, and the twin screw extruder is divided into two parts: flat, double and cone.

- Q: Where is the Huangyan extruder machine?

- You want to see what type of mold processing, but Masino comprehensive, injection mold, blow mold, mold and so on can be developed.

- Q: Taper twin screw extrusion machining of plastic masterbatch? What ancillary equipment do you need?

- Can, but need feeding machine and related auxiliary mixing granulator, the cost is not low, but the effect is less than double make flat,

- Q: Wire and cable extrusion machine extrusion die how to quickly adjust the core degree, how can I touch it by hand?,

- It depends on experience, and the lines made by squeezing it are solid. When you make the line, you can see the expansion and skewness of the material!

- Q: why production is not strong?I have several new co extrusion machines, but the blown plastic bags are not produced by others

- Tensile strength is divided between longitudinal and transverse, and PE bags are transversely increased, available 8CLLDPE is added, longitudinal can be added to medium, medium density or high-density material to increase tensile strength.

- Q: What is the principle of the 45 extruder machine?

- The principle of the extruder is the theoretical process of heating, melting and mixing in the process of plastic conveying, including solid conveying principle, melt transportation principle, mixing principle, and solid bed crushing process, etc..

Send your message to us

CMAX High Output Conical Twin-screw Plastic Extruder For High-speed Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords