Cheap Aluminium Coated Pet Mpet Film of Laminating Roll

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 100000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

cheap aluminium coated polypropylene pet mpet film of laminating film roll

Quality: 100% virgin pet

HS Code: 777309664

Processing Type: Multiple extrusion

Thinckness: 8mic-12mic

Main size: Width≤2350mm

Length 18000m/9000m/6000m

Usage: 1)PET food grade packing film2)PET printing film, pet release film

3)Metalized pet film,cpp/pet sealing film

4)Pet laminating film

Remark: All the indicators could be customized which includes the thickness, width, length, diameter.

Product Description

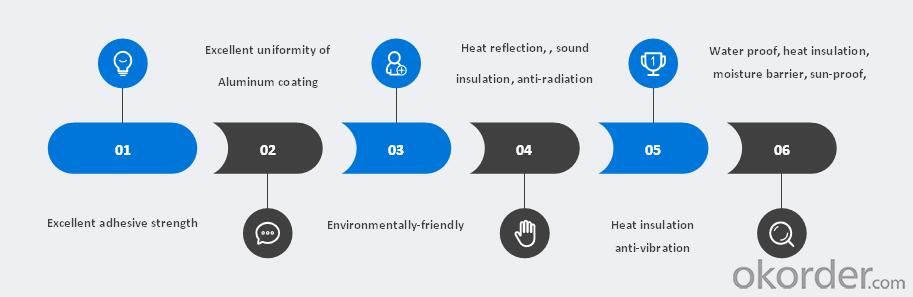

Our Advantage

Superiority of price: we control the whole process from raw materails purchasing to final product manufacturing.

Efficiency advantage: the fastest time of delivery is 7days.

Customization: all indicators could be customized which includes the thickness, width, length, diameter.

Usage

1) 12mic silver metalized PET film coated PE is used to laminated with EPE foam or Bubble as thermal Insulating materials, which could be used as underlay, wrap wall insulation materials,

2) To make sunshade or ice bag;

3) Used as emergency blanket, it can retains 80% percent of your radiant body heat

4) To make static shielding bag for electronic product

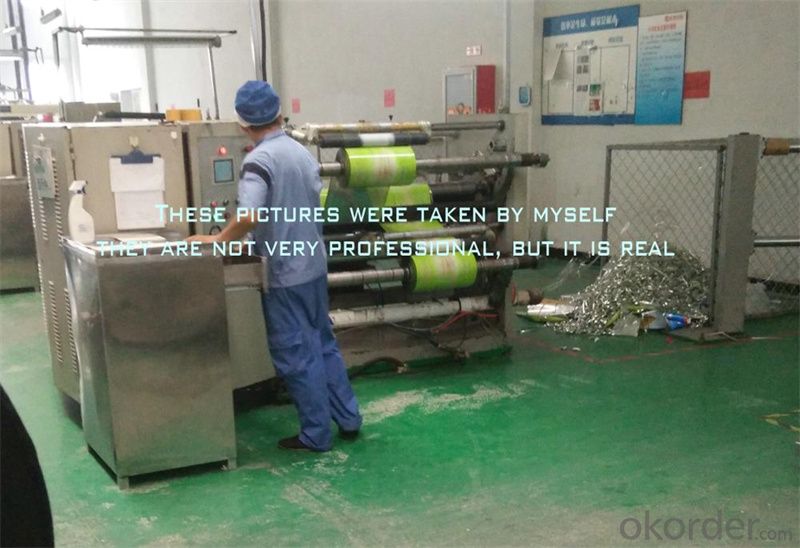

WorkPlace:

This is our metalized polyester pet film produce line,

you can visit our factory at anytime,

we asked workshop clean and tidy to ensure that the product with high quality and error-free.

Device Show

- Q: How much is plastic waste film?

- Waste plastic film is divided into many categories, depending on what material, PP, PE, PET, PVC, all kinds of prices.

- Q: Why should farmers cover plastic film when sowing in the spring?

- The film mulching can improve the soil and ground temperature and moisture status, to improve the soil temperature, soil water content, improve soil properties and improve soil nutrient status and fertilizer utilization rate, improve light conditions, reduce weeds and pests.

- Q: What are the LLDPE plastic films and what are the main uses?

- The properties of the resin are generally reflected in the melt index and density. The melt index reflects the average molecular weight of the resin and is mainly controlled by the reaction temperature. The average molecular weight has nothing to do with the molecular weight distribution (MWD). The influence of catalyst selection on MWD.The density is determined by the concentration of the comonomer in the polyethylene chain. The monomer density is used to control the number of short branches (whose length depends on the type of comonomer used) to control the resin density. The higher the concentration of comonomer, the lower the resin density.Structurally, LLDPE differs from LDPE in the number and type of branched chains, while high pressure LDPE has long branched chains, while linear LDPE has only short branched chains.Structurally, LLDPE differs only from HDPE in the number of short branches. HDPE has fewer short branched chains and therefore is of higher density.The physical properties of LLDPE are controlled by its molecular weight, MWD, and density.

- Q: What's the quota for PE membrane isolation layer?

- 0.4 thick polyethylene plastic film isolating layer, Beijing fixed no specific item, is paved with a layer of plastic cloth, can supplement the quota, labor costs by 0.5 yuan / square meters, according to the actual price included in the cost of materials.1.2 thick polyethylene geomembrane fixed: Materials 15 yuan / square meter, artificial 4 yuan / square meter.

- Q: What are the composite ways of plastic film?

- Dry composite method is to glue (glue) coated on a plastic film, and then through the drying of the excess solvent evaporation, and then hot roller and another kind of plastic film pressed together, a composite processing technology. This kind of compound processing technology has great flexibility in batch and quantity, and can be used for compound processing of many varieties and multilayer films. Suitable for complex products, small batch, a wide range of packaging products, composite processing. This kind of processing method is especially suitable for our country's food and small food variety, the pattern is diverse, the batch quantity is few, renovates fast characteristic. The disadvantage of the processing method is that the composite thin film (below 0.02mm film) is not good, the cost is expensive, and the residual adhesive, flux and odor are easy to be left. The glue dry laminating machine itself oven length, heating mode, glue way, glue feeding control, tension control, temperature control and heat drum have cooling device determines its price and grade level. At present, a large number of domestic dry composite is the use of two-component adhesives, small manufacturers and individual products are also using a single component adhesive. Water soluble adhesives meet the requirements of environmental protection and no residual solvents, but the plastic and plastic composite has not been used in batches, but only when the wet combination of metal foil and paper is adopted. The single component adhesive is not suitable for food packaging because of its high odor, non curing, temperature resistance and complex bonding.In addition to the long-term use of PE film as the material of composite, especially PE film composite thick, with particular attention to PE (polyethylene) film surface tension, usually should be more than 42~52dyn to ensure the firmness of the film (recommend that the machine in the laminating machine is installed on the spark office).

- Q: Keyboard circuit board, film paper and rubber strip, how is it installed?

- In the side of the conductive thin film circuit and the circuit board finger contact.

- Q: Wrap your legs in plastic film. How soon will they be removed?

- PE film is mainly used in:Industrial film packing products have high tensile strength, high elongation, good self adhesion and high transparency. The utility model is used for hand winding film and can also be used for machine winding film, and can be widely used for centralized packaging of various goods.

- Q: Can I use plastic film to make roofing waterproof?

- Not too good, poor corrosion resistance, can be used with waterproof cement tiles (can be thinner, cost saving) if there is a groove with a hose with waterproof ribbon, it has good corrosion resistance and decoration of a long time

- Q: What is the working principle of the manual plastic bag sealing machine?

- Working principle of manual plastic bag sealing machine:Plastic bag sealing machine is suitable for aluminum foil bag, plastic bag, compound bag and ideal sealing machine in medicine, pesticide, food, daily chemical, lubricating oil and other industries. The sealing machine is designed and manufactured on the basis of the advanced models at home and abroad, as well as the function of vertical and horizontal sealing. Applicable to all plastic film sealing and bag making, food factory, cosmetics factory, pharmaceutical and other units of the ideal sealing equipment, continuous operation, but also according to user needs to date, batch number, etc.. Suitable for assembly line work.

- Q: Why use plastic film wrapped legs running, weight loss good?

- Wearing a heavy sport suit or body sculpting exercise also temporarily reduces weight, and restores weight as soon as you add water." The best way to lose weight is for a small amount of exercise, a long period of exercise, while focusing on the requirements of a balanced diet. The general principle is that the exercise center rate is 120 times per minute, the duration of exercise lasts more than 45 minutes, the next day or every day, and attention to the diversity of sports events.

Send your message to us

Cheap Aluminium Coated Pet Mpet Film of Laminating Roll

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 100000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords