Cement Grinding Ball from CNBM China in Good Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Details: | (1) Steel Drums(with Pallet): 800-950KGS/Drum (2) Container Bags: 1000KGS/Bag (3) According to clients |

Delivery Detail: | Within 6-14 days |

Specifications

1.Grinding Ball Dia17-150mm

2.Wear-resistant,High impact value

3.High combined efficiency

4.Hardness 55-67HRC

5.Low breakage

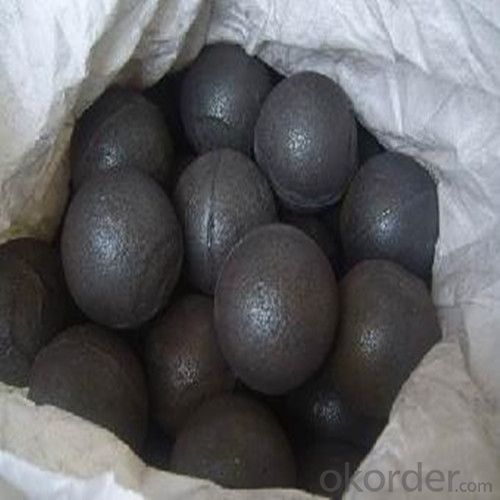

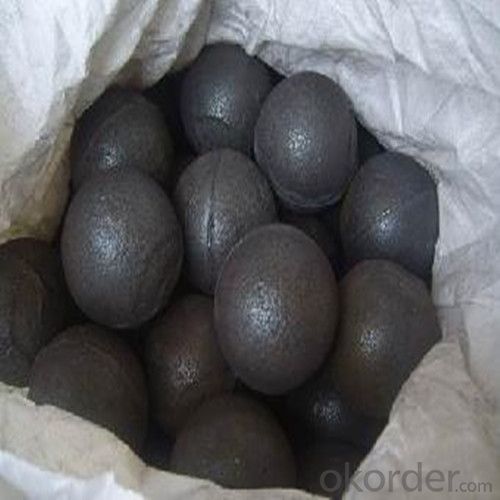

150MM Grinding Ball For Mine and Cement Plant

1.Feature:

1) High Hardness: surface hardness is to 55-68 HRC and volume hardness is to 50-63 HRC

2) High Impact Toughness: impact toughness is more than 12 J/cm2.

3) Low Broken Rate: the actual broken rate is not higher than 1%.

4) Even Wear-resistance: the loss of ball round rate is low.

2.Chemical Composition of Forged Grinding Ball

Based on material,the forged steel balls are defined into 7 brands. And The chemical composition is shown in the following:

Brand | Material | C | Mn | Si | Cr | S | P | V |

TITLE-1 | 50MN | 0.48-0.56 | 0.70-1.0 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 | |

TITLE-2 | 60MN | 0.57-0.65 | 0.70-1.0 | 0.17-0.37 | ≤0.25 | ≤0.030 | ≤0.030 | |

TITLE-3 | 65MN | 0.60-0.70 | 0.90-1.20 | 0.17-0.37 | ≤0.25 | ≤0.030 | ≤0.030 | |

TITLE-4 | 75Mn | 0.72-0.92 | 0.90-1.20 | 0.17-0.37 | ≤0.25 | ≤0.030 | ≤0.030 | |

TITLE-5 | 75MnCr(B2) | 0.70-0.85 | 0.7-1.20 | 0.17-0.37 | 0.4-0.8 | ≤0.030 | ≤0.030 | |

TITLE-6 | 75SiMn | 0.70-0.90 | 0.7-1.2 | 0.4-0.8 | ≤0.25 | ≤0.030 | ≤0.030 | |

TITLE-7 | Wear-resistant Alloy | 0.5-0.65 | 0.4-1.0 | 1.4-1.8 | 0.9-1.2 | ≤0.030 | ≤0.030 | 0.1-0.2 |

3.Chemical Composition of Casting Grinding Ball

Based on material,the casting steel balls are defined into 6 brands. And The chemical composition is shown in the following:

Name | Model | Material | C | Si | Mn | Cr | S | P |

TITLE-8 | High Chrome | Cr-22-32% | 2.0-2.8 | ≤1.0 | 0.5-2.0 | 22-32 | ≤0.01 | ≤0.01 |

TITLE-9 | Cr-17-22% | 2.0-2.8 | ≤1.0 | 0.5-2.0 | 17-22 | ≤0.01 | ≤0.01 | |

TITLE-10 | Cr-14-17% | 2.2-3.0 | ≤1.0 | 0.5-2.0 | 15-17 | ≤0.01 | ≤0.01 | |

TITLE-11 | Cr-10-14% | 2.2-3.2 | ≤1.0 | 0.5-2.5 | 11-14 | ≤0.01 | ≤0.01 | |

TITLE-12 | Medium Chrome | Cr-5-10% | 2.1-3.2 | ≤1.2 | 0.5-1.5 | 5-10 | ≤0.01 | ≤0.01 |

TITLE-13 | Low Chrome | Cr-1-5% | 2.2-3.5 | ≤1.2 | 0.5-1.5 | 1-5 | ≤0.02 | ≤0.02 |

4.Specification of Grinding Ball

5.Specification of Casting Grinding Ball

1)High chrome cast balls

Size: 20mm-150mm

Hardness:HRC58-65; Chrome content:11-14%

2)Low chrome cast balls

Size: 20mm-150mm

Hardness:HRC45-55; Chrome content:1-5%

6.Main Process of Forged Steel Ball

(1)Raw material.(2)Cutting.(3)Heating.(4)Forging.(5)Quenching.(6)Tempering.(7)Testing.(8)Qualified Products.(9)Packing

7.Main Process of Casting Grinding Ball

(1)Raw material.(2)Scientific Proportioning.(3)Electric Furnace Smelting.(4)Assay Before Furnace.(5)Mould Forming.(6)Polishing.(7)Heat Treatment.(8)Qualified Products.(9)Packing

8.Applied Field

1).Cement Plants 2).Mines 3).Power stations 4).Chemical Industries 5).Grinding Mill, Ball mill, Coal mill

9. Products Name

Grinding Ball, Steel Ball, Grinding Rod, Grinding Bar, Grinding Cylpebs, Ball Mill Liner Plate, Grinding Steel Ball, Grinding Iron Ball, Mill Ball, Forged Steel Ball, Forging Steel Ball, Forged Grinding Ball, Forging Grinding Ball, Forged Ball, Forging Ball, Forged Grinding Steel Ball, Forged Steel Grinding Ball, Cast Grinding Ball, Casting Grinding Ball, Casted Grinding Ball, Cast Iron Ball, Casting Ball, Cast Ball, Casted Ball, High Chrome Cast Ball, High Chrome Casting Ball, High Chrome Cast Grinding Ball, High Chrome Cast Iron Ball, High Chrome Ball, Low Chrome Cast Ball, Low Chrome Casting Ball, Low Chrome Cast Grinding Ball, Low Chrome Cast Iron Ball, Low Chrome Ball, Medium chrome cast grinding ball, Medium Chrome Casting Ball, Medium Chrome Cast Grinding Ball, Medium Chrome Cast Iron Ball, Medium Chrome Ball,Grinding Ball, Steel Ball, Grinding Steel Ball, Steel Grinding Ball,Grinding Media, Grinding Media Steel Ball, Cement Mill Grinding Media, Steel Grinding Media Mill Ball, Grinding Media Steel Ball,Iron Grinding Ball For Ball Mill, Grinding Mill Ball, Mill Grinding Media Balls, Cement Milling Steel Balls For Mill, Forged Grinding Ball For Mill, Forged and Casting Grinding Steel Ball,Forged Steel Grinding Ball, Forged Steel Grinding Media Ball,Steel Grinding Mill Ball, Forged Steel Media Ball, Forged Grinding Steel Mill Balls, Wear-resistant Steel Ball Grinding Media, 20mm-150mm Wear Resistant Grinding Steel Ball, Forged Steel Grinding Balls, 150MM Grinding Ball For Mine and Cement Plant

10. Packaging

(1) Steel Drums(with Pallet): 800-950KGS/Drum

FAQ:

1. Q:Are you a manufactory or trading company?

A:We are a professional manufactory with 12 years’ experience and 2 years of export experience, covers an area of 30 acres.

2. Q: May I know your MOQ request?

A:MOQ is 1 TON.

3. Q: Could you offer free sample?

A:We can provide free samples to you for quality testing.

4. Q: Does your product is dangerous merchandise?

A: Not dangerous merchandise, It belongs to Not legal Inspection merchandise.

5. Q: What about your packing?

A: Liquid in IBC tank or Flexitank;Powder in woven bags.

6. Q: How about your productive capacity?

A: 900000 tons/Year.

7. Q: What is your export port?

A: China main port.

8. Q: What is your delivery time?

A: Within 7 days after received advanced payment.

9. Q: Can you print logo or label on packing as customer request?

A: Yes, we can customize according to your requirements.

- Q: How to improve the surface roughness of casting parts?

- First, the accuracy of the model should be improved; two is to change the molding technique; the three is the coating; and the worker's technical level.

- Q: The casting defects of pores, trachoma how to repair?

- Metal repair can be used to fill the repair. Airhole 2mm following LT102 recommend the use of liquid metal repairing agent.

- Q: the parts of the threaded hole is casting, casting the hole directly, and then tapping or casting, and then punch 10When the casting is ready, punch it again before tapping it Is the hole casting good or is it punched and tapped on the drilling machine after casting?

- If it is not directly cast hole hole, later processing, large pores may be directly cast out,

- Q: What is the reason for 304 stainless steel precision casting parts to be changed?

- 304 stainless steel is easier to change than ordinary steel. Because the 304 heat conductivity is lower than that of the low doped steel, the temperature is even more uneven, and 20% of the non ferrous elements also make the distribution of internal and external elements more uneven, hard and soft inside. Each of these two produces greater internal stresses, resulting in a variant.

- Q: The cause of fracture and why there is no toughness

- This question is too broad, see what the casting casting Oh in order to reduce the wayward cast steel, ductile iron, gray iron and white iron, you can choose the material according to their own requirements.

- Q: What's the density of the cast iron? The density is thin and the density is thin

- Uneven casting density is caused by uneven shrinkage of the casting during solidification.

- Q: How can the casting be quenched and tempered?

- Another is the result of pre heat treatment (quenching or annealing) after quenching and tempering treatment, suitable for ZG35SiMNMo, ZG35CrMo and so on. Please tell the casting process is your product and material and then set tempered.: shutup:

- Q: What are the causes of pitting on the surface of a precision casting?

- There is a bump on the mold. Or casting cooling fast.

- Q: Why should pig iron be used in casting?

- Not necessarily is iron, steel, stainless steel, aluminum, copper can be cast iron, is cheaper, and better properties of cast out, for example, is not easy to rust, high strength, easy processing and so on, and is the only iron iron cast out, it is not necessarily the raw pig iron, plus some other material

- Q: Shandong foundry, casting small pieces of precision casting

- Small foundry in Shandong too much, like many of us in Qingdao, then Dongying Changshun investment casting is a home, they are also casting precision casting equipment, specifically what I recommend that local enterprises, far is not convenient,

Send your message to us

Cement Grinding Ball from CNBM China in Good Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords