Cement Grinding Aid in Concrete from CNBM China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Cement grinding aid

High-efficient cement grinding aids, co-developed & produced by Tsinghua University with Zhengzhou Chengzhi Co., Ltd,is a scientific allocation

Of several kinds of organic polymer surfactant. Non-toxic, non-corrosive, no adverse effects on cement. The product complies with the building materials industry JC/T667-2004 " cement grinding aids " standard, the adding amount should not exceed 0.5% of the cement mass; new national standard also increased the requirements on the limit of chloride ion, namely: the chloride ion content in cement should not exceed 0.06%. This product can be widely used in various types of cement production enterprises.

Function principle and Application scope:

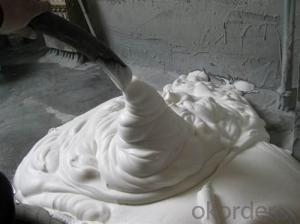

Grinding miller use mechanical force to micronize the solid material, during the grinding process, crashing and smashing occurs between materials and the ball forging media, makes the particles inside electrovalent bond cut off, to form a charge unit that generates static electric, adsorbing on the medium surface, appear to be pastes surrounding the grinding, thus cause energy waste, restricting the production.

CZZM series can effectively reduce materials’interfacial tension, reduce friction, clear away pastes surrounding grinding phenomenon, improve the powder flowability and avoid over-grinding phenomenon, thus achieve the effect of heightening the mill production. At the same time along with more reasonable distribution on the cement particle size and increasing trace active elements, the cement strength in each age have been strengthened, the cement fluidity has significantly increased.

High performance liquid cement grinding aids is applicable to ordinary portland cement, slag cement, fly ash cement, pozzolana cement, Portland cement and other cement composite production.

Performance:

1. To improve the cement mill output : After adding the aids, under the premise of maintaining or slightly improving the cement’s physical properties, the mill production capacity can be increased by 10 %.

2. Reduce the mill consumption: by improving the powder’ surface charge performance inside the mill, it can eliminate the " pastes surround the grinder" phenomenon; meanwhile the aids can improve the micro- cracks’ extending of the powder particles, improve the grinding efficiency, thereby reduce the miller energy consumption, cement mill per tonne of power consumption can be reduced by 10-20% .

3. To prevent " excessive grinding " and reduce the grinding temperature : because of the grinding efficiency’s raising, accelerate the cement mill’s passing speed, to avoid " over-grinding " phenomenon, thus reducing the mill inside temperature. Grinding temperature’s decrease can prevent dihydrate gypsum’s dehydration, to improve the setting time and strength development and other cement performance.

4. To improve the cement’s physical performance: to improve the cement strength ( especially 10-20 % improve the early strength) or shorten setting time ( especially the final setting time ) ; take advantage of added the grinding aids can help improve the cement’s performance, can increase the mixing content amount, or add of part of the shaft kiln cement clinker in rotary kilns to reduce costs.

5. To reduce powder surface adsorption energy: Adding the aids can help reduce powder surface’s static enrichment, to avoid the powder clumping and compaction to harden, eliminating cement silo bottom "bonding " phenomenon ; improve powder mobility, reduce transportation energy consumption;

6. Economic analysis by using cement grinding aids (Take 100T per year output cement companies for example )

Specifications

Mainly used in the sector of pharmaceuticals, pesticide, synthetic fiber, electroplating, photography, accelerator for cement.

Synonyms:Sodium Rhodanide, Sodium Sulfocyanate, Sodium Rhodanate, Sodium Isocyanate, Thiocyanic Acid, Sodium Salt

Molecular Formula: NaSCN

Molecular Weight: 81.07

Properties: Sodium thiocyanate, a white rhombic system crystal, is soluble in water, ethanol, acetone; Relative density is 1.735. Melts at approx.287°C. decomposes on heating and under influence of light producing toxic fumes of sulfur oxides,nitrogen oxides and cyanides. Reacts violently with acids,strong bases and strong oxidants.

Packing: 25 kgs net in PP bag with inner of polyethylene bag.

Storage: Keep Sodium thiocyanate in tightly closed bags.Store in cool, dry, ventilated area to prevent it from being deliquescent. Separated from acides, bases and oxidants.

Application type | Top grade | Top grade | Top grade | Top grade |

Assay%,(Dry base)≥ | 99 | 98 | 97 | 50-55 liquid |

Ferrum %,≤ | 0.0001 | 0.0002 | 0.0003 | 0.0001 |

Water insolubles%,≤ | 0.003 | 0.005 | 0.005 | 0.001 |

Moisture%,≤ | 0.5 | 1.0 | 1.0 | -- |

Chloride %,≤ | 0.01 | 0.02 | 0.04 | 0.01 |

Sulphate%,≤ | 0.02 | 0.04 | 0.05 | 0.015 |

Heavy metal %,≤ | 0.001 | 0.0015 | 0.0015 | 0.0005 |

PH | 6-8 | 6-8 | 6-8 | 6-8 |

FAQ:

1. Q:Are you a manufactory or trading company?

A:We are a professional manufactory with 12 years’ experience and 2 years of export experience, covers an area of 30 acres.

2. Q: May I know your MOQ request?

A:MOQ is 1 TON.

3. Q: Could you offer free sample?

A:We can provide free samples to you for quality testing.

4. Q: Does your product is dangerous merchandise?

A: Not dangerous merchandise, It belongs to Not legal Inspection merchandise.

5. Q: What about your packing?

A: Liquid in IBC tank or Flexitank;Powder in woven bags.

6. Q: How about your productive capacity?

A: 900000 tons/Year.

7. Q: What is your export port?

A: China main port.

8. Q: What is your delivery time?

A: Within 7 days after received advanced payment.

9. Q: Can you print logo or label on packing as customer request?

A: Yes, we can customize according to your requirements.

Send your message to us

Cement Grinding Aid in Concrete from CNBM China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords