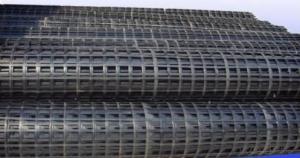

CE Certified T1000 Polypropylene Biaxial Geogrid Geotextile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Each roll per 3 plastic belts. Other packages can be done as per request. |

| Delivery Detail: | For 40HC,within 10 days after receipt of L/C or down payment |

Specifications

Biaxial Geogrid

1.CE,ISO

2.Biaxial Geogrid Strength:15-45kn/m

3.Biaxial Geogrid Width:3.9m,3.95m,4m

4.Geogrid Length:30m,50m

Biaxial geogrid can be used to enhancement of permanent bearable toft including roads and

railways embankment, slopes, tunnel, airfields, parks, docks and ground which cargo lays on and

their main usage are as follows:

1.Enhance the bearing capacity of road foundation and extend the duration of roads.

2.Prevent road surface from collapse, crack and being dirty.

3.Be convenient for construction, timesaving and cut down the cost of maintenance.

4.Prevent tunnel from crack occurring.

5.Further solidity slopes to proof water and soil from losses.

6.Reduce the surface thickness of the ground.

7.Consolidate the net for growing grass on the slopes so as to stabilization surrounding virescence.

8.Be used for artificial top net of mines instead of metal ones.It is of fire-retardant and anti-statics.

[Specifications And Characteristics]

Item | TGSG15-15 | TGSG20-20 | TGSG30-30 | TGSG40-40 | |||||

Unit | MD | CD | MD | CD | MD | CD | MD | CD | |

True initial Modulus in Use | KN/m | 15 | 15 | 20 | 20 | 30 | 30 | 40 | 40 |

True Tensile Strength @2% Strain | KN/m | 5 | 5 | 7 | 7 | 11 | 11 | 16 | 16 |

True Tensile Strength @5% Strain | KN/m | 7 | 7 | 14 | 14 | 21 | 21 | 32 | 32 |

Junction Efficiency | % | 100 | 100 | 100 | 100 | ||||

Flexural Stiffness | mg-cm | 280.000 | 780,000 | 900,000 | 1,200,000 | ||||

Aperture Stability | kg-cm/deg | 3.1 | 4.8 | 4.3 | 3.4 | ||||

Resistance to Installation Damage | %SC/%SW/%GP | 95/93/90 | 95/93/90 | 95/93/90 | 95/93/90 | ||||

Resistance to Long Term Degradation | % | 100 | 100 | 100 | 100 | ||||

Unit Weight | g/m2 | 300±30 | 330±30 | 400±40 | 500±50 | ||||

Rolls Dimensions (Length, Width) | m | 50×3.95 | 50×3.95 50X5 | 50×3.95 | 50×3.95 | ||||

Lading Capacity | Rolls/40HC | 300 | 260 | 140 | 100 | ||||

- Q: Can geotextiles be used for soil reinforcement in embankments?

- Yes, geotextiles can be used for soil reinforcement in embankments. Geotextiles are commonly used in civil engineering projects to improve the stability and strength of soil structures. They are effective in preventing soil erosion, enhancing drainage, and distributing loads, making them suitable for reinforcing embankments and preventing slope failures.

- Q: Alteration of highway seepage control geotextile is generally placed in what position

- Apply to the grassroots level of water defense, the use of embedded, covered with thickness should not be less than 30CM, soil to be solid, to avoid uneven subsidence, cracks. Lap width should be greater than 15CM.

- Q: Polyester non-woven and geotextile is not the same, what is the difference?

- Geotextile according to the production process is divided into spinning and non-woven, spinning is latitude and longitude to weave together, non-woven is the use of acupuncture or spunlace and other means of production. Geotextile is also a lot of raw materials, there are polyester, polypropylene, nylon, and other raw materials. You said that the polyester non-woven polyester raw materials is non-woven production process, is a geotextile.

- Q: Welding of impervious geotextile

- 1. Seam processing is the key to the construction process, the general use of heat welding method, PE film surface heat treatment, so that the surface melting, and then through the pressure, so that one fusion. 2. For the laying of a good geomembrane, edge seams require no oil, water, dust and so on. 3. Before welding to adjust the seam at the two sides of the PE single film, so that a certain width of the lap, lap width is generally 6 ~ 8 cm and smooth, no wrinkles. 4. Use special welding machine for welding. Welding construction effect map:

- Q: What are the environmental impacts of geotextile production?

- The environmental impacts of geotextile production primarily include energy consumption, greenhouse gas emissions, and waste generation. The production process requires significant amounts of energy, mainly derived from fossil fuels, leading to carbon dioxide emissions and contributing to climate change. Additionally, the extraction and processing of raw materials for geotextiles can result in habitat destruction and soil degradation. Furthermore, the production process generates waste, such as wastewater, air emissions, and solid waste, which can have adverse effects on local ecosystems if not properly managed.

- Q: Concrete pavement or geotextile

- Do not add, with the asphalt Ma plug Seal if you have to choose the best choice for geotextile waterproof the best

- Q: How are geotextiles different from other types of geosynthetics?

- Geotextiles are a type of geosynthetic material that is primarily used for filtration, separation, and reinforcement purposes in various civil engineering applications. Unlike other types of geosynthetics such as geogrids or geomembranes, geotextiles are typically made from woven or non-woven fabrics, which provide them with unique characteristics like high permeability, flexibility, and resistance to biological degradation. These properties enable geotextiles to effectively filter water, prevent soil erosion, and improve soil stability, distinguishing them from other geosynthetics that may have different functions or structural compositions.

- Q: How do geotextiles help in reducing the risk of slope failures?

- Geotextiles help in reducing the risk of slope failures by providing reinforcement and stabilization to unstable slopes. These materials are placed within the slope to increase its strength and prevent erosion. Geotextiles also help in promoting water drainage and filtration, which reduces the build-up of hydrostatic pressure within the slope. Overall, geotextiles enhance the stability of slopes and mitigate the potential for landslides or slope failures.

- Q: How do geotextiles help in stabilizing slopes for pipeline construction?

- Geotextiles help in stabilizing slopes for pipeline construction by providing reinforcement and erosion control. They are placed along the slope to prevent soil erosion and promote stability. The geotextiles act as a barrier, preventing the movement of soil particles and reducing the risk of slope failure. Additionally, they enhance the soil's strength and increase its resistance to erosion caused by water flow. Overall, geotextiles play a crucial role in maintaining the stability of slopes during pipeline construction.

- Q: Are geotextiles suitable for use in coastal erosion control?

- Yes, geotextiles are suitable for use in coastal erosion control. They are commonly used to stabilize slopes, prevent soil erosion, and protect shorelines from wave action. Geotextiles can be installed as a barrier to filter sediment and retain soil while allowing water to pass through, effectively controlling erosion in coastal areas.

Send your message to us

CE Certified T1000 Polypropylene Biaxial Geogrid Geotextile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords