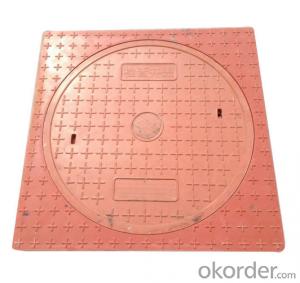

Casted Ductile Iron Manhole Covers B125 and C250 for industry with Competitive Prices Made in Hebei

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1) production standard: EN124 from A15 to F900

2) Material: grey iron, ductile iron

3) ISO9001:2008

4)Standard:ISO9001,EN124

5)Applicable medium:gases,liquids,steam

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) | Frame Height(mm) | Unit Weight (kg/set) |

| PBC700 | B125 | 600×600 | 700×700 | 40 | 37 |

Advantages

Good compressive, water-proof, anti-corrosion, not rust, long service life (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than other companies.

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

FAQ

1.Can I get free samples?

A: Yes, we can provide you the free sample, but you need to bear their own delivery costs.

2.Can I have my own Logo on the product?

A: Yes, you can send us your drawing and we can make your logo, but you have to bear their own the cost.

- Q: What are the casting parts used to test shrinkage holes?

- 2. x ray. This method can do nondestructive testing, but the cost is higher. Generally, high castings are required.

- Q: The casting defects of pores, trachoma how to repair?

- If the repair after the high temperature resistance, choose LT737 high temperature repair agent.

- Q: our factory now produces steel castings in the use of polishing directly after spraying processing, but the powder sprayed 15But the spray powder touched off what is the reason we are not very strict requirements not only need to peel off bubbles can also, because our products are steel castings so we use steam hole sludge put on. Do not know if this spray treatment has no effect to thank friends with us!

- Usually after rusting,Did you peel it?If it isNeed to do film processingIf notPlease look for the coating factoryBetter paint (such as epoxy ester, etc.)

- Q: Casting parts by shot blasting, spray painting, baking after the formation of very small rust spots, how to solve ah?

- The first process is very important. Shot blasting must be thorough. The solution is to wipe the surface of the paint with a release. Re shot

- Q: What kind of casting process is used for cast iron parts? And what are the cast steel parts adopted?

- The main content of red sand table (Institute of soil science, China) silica 79.4%. three 1.48%. three 10.55%. two aluminum oxide iron oxide, calcium oxide 0.85%. Magnesium Oxide 0.52%. 1440. refractory mud 3.06% LOI 1.98% red sand with high silicon content, permeability is strong, durable, high refractoriness, good angle, low moisture content, less mud the casting finish is high, the basic requirements of sand should meet the following requirements: Casting of high purity and cleanliness, with silica sand as an example, iron sand SiO2 content of more than 90%, the big steel casting requests the SiO2 content of more than 97%; the high refractoriness and thermal stability; the suitable particle the shape and particle composition; it is not easy to be wetted by the liquid metal; cheap. The particle shape and composition of casting sand particle shape and particle composition permeability properties such as mobility, sand compaction, permeability, strength and resistance to liquid metal effects, is an important indicator of the quality of casting sand.

- Q: In theory, which is more expensive, forging parts or casting parts?

- The structure of the casting is relatively flexible in design, and the modeling is easy to realize.

- Q: Casting parts have poor surface finish. What sand is used to make them?

- Now resin sand, coated sand and other processes are also very good surface.

- Q: How do you mark it on the drawing? Do you need to discuss it with the manufacturer?Because the casting allowance is the standard, then, after all, is the theoretical value, the actual level depends on the manufacturer, so is it necessary to ask the manufacturer?

- The general foundry casting technology division will mark put shrinkage and the allowance of the map in your chart (usually with the red pen) for the production of wood or other material wood workers die drawings.

- Q: Cause of choking of casting parts

- Is it boiling from the picture? Does it sound like a fire? If not, it's not choking. I feel like choking. The gas doesn't drain out

- Q: When there is no flaw detection for large casting parts, is there any crack inside?

- According to the industry standards, within the scope of the standard requirements to determine whether the product is qualified

Send your message to us

Casted Ductile Iron Manhole Covers B125 and C250 for industry with Competitive Prices Made in Hebei

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches