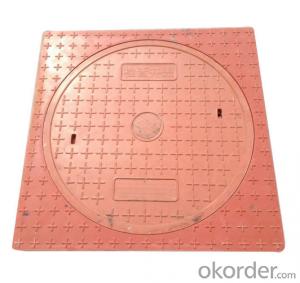

Cast Ductile Iron Manhole Covers B125 and C250 for industry with Competitive Prices Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1) production standard: EN124 from A15 to F900

2) Material: grey iron, ductile iron

3) Type: round type and Square type, triangle

4) ISO9001:2008

5) Material:

a) Grey cast iron (GG)

Type description EN-GJL-200/-300

Tensile strength 100 – 400 N/ mm²

Elongation < 1 %

Loading 400 – 800 N/ mm²

Density 7.8 kg/ dm³

Property very hard / brittle

b) Ductile Iron (GGG)

Type description EN-GJS-400/-700

Tensile strength 500 – 1100 N/ mm²

Elongation 2 – 15 %

Loading 700 – 1300 N/ mm²

Density 7.8 kg/ dm³

Property deformable

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) |

| PBC700 | B125 | 600×600 | 700×700 |

Advantages

Good compressive, water-proof, anti-corrosion, not rust, long service life (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than other companies.

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

FAQ

1.Can I get free samples?

A: Yes, we can provide you the free sample, but you need to bear their own delivery costs.

2.Can I request to advance the shipment?

A: It should be depends on whether there is sufficient inventory in our warehouse.

3.Can I have my own Logo on the product?

A: Yes, you can send us your drawing and we can make your logo, but you have to bear their own the cost.

4.Can I get after-sale service?

A:Yes,we provide after sale service as well.

- Q:How to improve the surface roughness of casting parts?

- One is to improve the accuracy of the model; the two is to improve the molding sand mesh. How much is the other relationship?.

- Q:What is normalizing, annealing, tempering, quenching? What is the difference between forging parts and casting parts?

- For the nodular cast iron, the hardness, strength and wear resistance are improved, such as used in the manufacture of automobile, tractor, diesel engine crankshaft, connecting rod and other important parts. A normalizing and hypereutectoid ball annealing before, can eliminate the mesh two cementite spheroidizing annealing, to ensure that all spheres of cementite. Annealing is a metal heat treatment process, which means the metal is slowly heated to a certain temperature, sufficient for a long time, and then cooled at an appropriate speed. The purpose is to reduce hardness, improve machinability, eliminate residual stress, stabilize size, reduce deformation and crack tendency, refine grain, adjust microstructure and eliminate tissue defects. Its purpose: (1) reduce hardness and improve machinability; (2) eliminate residual stress, stabilize size, reduce deformation and crack tendency; (3) refine grain, adjust microstructure and eliminate tissue defects. In production, annealing process is widely used.

- Q:How to solve casting defect casting?

- Different defects, different solutions, some shortcomings, the current domestic level can not be resolved

- Q:What kind of flaw detector is better for casting parts?

- If you want to detect internal defects, you can use ultrasonic flaw detector, ray flaw detector can also, but the ray of the safety protection level is too high, not recommended priorityMacro Xu flaw detector answered, such as the magnetic particle inspection machine has the demand can contact us, Baidu "macro Xu flaw detection""

- Q:How much is the amount of electrophoretic paint per square meter used in the casting?

- In general, when the final thickness of 15-20 microns, cathode electrophoresis paint can be coated per kilogram of 6-8 square meters, the current general cathode electrophoresis paint for the price of 22 yuan / kg, so the cathodic electrophoresis electrophoresis paint cost at 4 yuan / square meters.

- Q:What is the casting material?

- Kdl1588n said in detail, casting a lot of material, steel, iron, aluminum, copper, zinc, etc. can be, valuable, as well as gold and silver, the most common on cast steel and cast iron, cast aluminum and so on.

- Q:What's the effect of casting copper?

- In general cast iron, the mass fraction of copper below 3% - 3.5% can increase the hardness; but when the cast iron has a tendency to chill, or when there is a hard point of free carbides, the addition of copper decreases the hardness.Copper can be used to improve the wear resistance, abrasion resistance, and shock absorption of cast iron, so it is often used in the manufacture of sliding friction iron castings, such as drilling machine spindle, automobile and tractor, valve tappet, etc.. But in white cast iron or chilled cast iron, adding copper does not make any improvement in its abrasion resistance.Copper for certain heat resistant cast iron and austenitic cast iron can increase the heat resistance and corrosion resistance, copper - chromium composite alloy to prevent oxidation under high temperature in the atmosphere from the skin effect is particularly effective, heat resistance and corrosion resistance of austenitic cast iron containing many mass fraction of 4% ~ 7% copper.

- Q:I often see Waixiejiagong drawings, casting, how to distinguish the latheman.

- Yes, casting drawings are casting drawings with machining allowances, slopes, and gating systems

- Q:Which master knows how the casting tolerances for malleable iron, gray iron and ductile iron should be chosen? Hurry up, thank youCan you provide a tolerance scale for castings, please?

- The tolerance of a specific size can be obtained from the tolerance grade and nominal size of the casting.

- Q:After reaming, the roughness can reach several levels, that is to say, the sample.Casting parts in rocker arm drilling, reaming, roughness, block. After reaming, the roughness can reach several levels, that is to say, the sample.

- The finish of reaming depends on the material and the sharpness of the reamer, as well as the speed and speed of the top and bottom. Marine machine tool

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cast Ductile Iron Manhole Covers B125 and C250 for industry with Competitive Prices Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords