Carton Seamless Steel Pipe ASTM A106/API 5L/ASTM A53 GR.B

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Seamless Balck Pipe ASTM A106/API 5L/ASTM A53 GR B:

Seamless pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell. As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable. Historically seamless pipe was regarded as withstanding pressure better than other types.

2、Main Features of Seamless Balck Pipe ASTM A106/API 5L/ASTM A53 GR B:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

3、Seamless Pipe ASTM A106/53 Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Seamless Balck Pipe ASTM A106/API 5L/ASTM A53 GR B:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

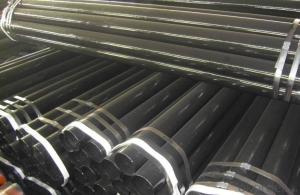

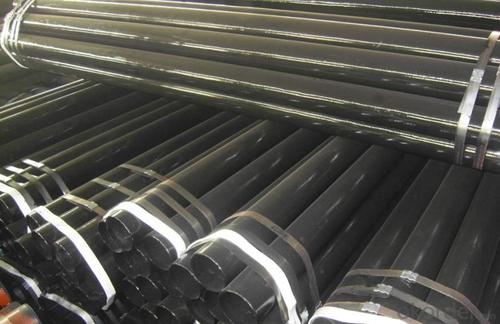

6、Seamless Pipe ASTM A106/53 Images:

- Q: How do you transport steel pipes safely?

- Transporting steel pipes safely requires proper planning, equipment, and adherence to safety measures. Here are some guidelines to ensure the safe transportation of steel pipes: 1. Choose appropriate transportation equipment: Use a flatbed trailer or a truck with a flatbed to transport steel pipes. Ensure that the trailer or truck has a strong and secure tie-down system to prevent the pipes from shifting during transit. 2. Secure the pipes: Use nylon or steel straps to secure the steel pipes to the trailer or truck bed. Make sure the straps are tightened properly, evenly distributing the weight of the pipes and preventing any movement or shifting. 3. Protect the pipes: Use pipe chocks or padding materials such as foam or rubber to prevent the pipes from rolling or rubbing against each other during transportation. This helps to minimize potential damage and maintain the integrity of the pipes. 4. Observe weight limits: Ensure that the weight of the steel pipes being transported does not exceed the load capacity of the transportation equipment. Overloading can lead to instability and compromise safety. 5. Follow road safety regulations: Adhere to all local traffic laws and regulations, including speed limits and securing all necessary permits or licenses for oversized loads if required. Additionally, use hazard warning signs or flags when transporting long or oversized steel pipes to alert other road users. 6. Conduct regular inspections: Before starting the journey, inspect the straps, tie-downs, and other securing mechanisms to ensure they are in good condition. Regularly check the load during transit to ensure it remains secure. 7. Plan the route: Choose a route that is suitable for the size and weight of the steel pipes being transported. Avoid roads with low bridges, narrow lanes, or weight restrictions that may pose a risk to the safe transportation of the pipes. 8. Consider weather conditions: Take into account weather conditions, such as strong winds or heavy rain, which can affect the stability of the load. Adjust the transport plan accordingly or delay the journey if necessary. 9. Train and educate drivers: Ensure that the drivers responsible for transporting steel pipes are well-trained and aware of the proper procedures for securing and transporting the load safely. Regularly update them on safety protocols and any changes in regulations. By following these guidelines, you can transport steel pipes safely, minimizing the risk of accidents, damage to the pipes, and ensuring the safety of everyone involved in the transportation process.

- Q: Can steel pipes be used for steam distribution?

- Yes, steel pipes can be used for steam distribution. Steel pipes are commonly used in steam distribution systems due to their high strength, durability, and resistance to high temperatures and pressure. They can effectively handle the transportation of steam in various industries such as power generation, chemical processing, and heating systems.

- Q: Can steel pipes be used for conveying sewage and wastewater?

- Yes, steel pipes can be used for conveying sewage and wastewater. Steel pipes are commonly used in sewage and wastewater systems due to their durability and strength. They are resistant to corrosion and can withstand high pressure and flow rates. Additionally, steel pipes are able to handle the harsh chemicals and contaminants present in sewage and wastewater without deteriorating or affecting the quality of the conveyed fluids. However, it is important to ensure that the steel pipes are properly coated or lined to prevent any potential corrosion or contamination issues. Regular maintenance and inspections are also necessary to identify and address any potential issues that could arise in the system.

- Q: How are steel pipes used in the construction of industrial facilities?

- Steel pipes are commonly used in the construction of industrial facilities for various purposes such as transporting fluids, gases, and steam, as well as providing structural support and carrying electrical wiring. They are durable, resistant to corrosion, and can withstand high pressure and temperature, making them ideal for industrial settings.

- Q: Are steel pipes affected by magnetic fields?

- Yes, steel pipes can be affected by magnetic fields. Steel is a ferromagnetic material, which means it is strongly attracted to magnets and can be magnetized. When exposed to a magnetic field, steel pipes can become magnetized, causing them to behave like magnets themselves. This magnetic effect can have several implications. First, if steel pipes are near strong magnetic fields, such as those generated by electrical currents or powerful magnets, they can experience a force that may cause them to move or vibrate. This can be problematic in certain applications, especially if the pipes need to remain stable and secure. Second, the presence of magnetic fields can induce electrical currents in steel pipes. These currents, known as eddy currents, can generate heat and energy losses. In some cases, this can lead to inefficiencies and increased energy consumption in systems that involve steel pipes. Lastly, magnetic fields can also affect the accuracy of magnetic measurement devices used to detect defects or corrosion in steel pipes. The presence of a magnetic field can interfere with the readings, making it more challenging to accurately assess the condition of the pipes. To mitigate these effects, various measures can be taken. For instance, in applications where stability is crucial, steel pipes can be shielded or isolated from strong magnetic fields using non-magnetic materials. Additionally, the impact of eddy currents can be minimized by using pipes with proper insulation or by using magnetic shielding techniques. Overall, while steel pipes are indeed affected by magnetic fields, the extent of the impact depends on factors such as the strength of the magnetic field, the composition of the steel, and the specific application or environment in which the pipes are used.

- Q: What is galvanized steel pipe?

- Galvanized steel pipe is a type of steel pipe that has been coated with a layer of zinc, which helps protect it from corrosion and rust. This coating also increases the pipe's longevity and makes it suitable for various applications, including plumbing, construction, and outdoor structures.

- Q: How do steel pipes connect to other components?

- Steel pipes can connect to other components through various methods such as welding, threading, flanges, or mechanical couplings.

- Q: How do you calculate the pipe pressure loss coefficient for steel pipes?

- To calculate the pipe pressure loss coefficient for steel pipes, you can use the Darcy-Weisbach equation, which is a widely accepted method for determining the pressure loss in pipes due to friction. The equation is as follows: ΔP = f × (L/D) × (V^2/2g) Where: - ΔP is the pressure loss (in units of pressure, such as psi or Pa) - f is the Darcy friction factor (dimensionless) - L is the length of the pipe (in units of length, such as feet or meters) - D is the diameter of the pipe (in units of length, such as feet or meters) - V is the velocity of the fluid flowing through the pipe (in units of velocity, such as ft/s or m/s) - g is the acceleration due to gravity (in units of acceleration, such as ft/s² or m/s²) The Darcy friction factor (f) is a dimensionless parameter that represents the amount of frictional resistance in the pipe. For steel pipes, the friction factor can be determined using the Moody diagram, which is a graphical representation of the relationship between the Reynolds number (Re) and the friction factor (f) for different pipe roughness. To calculate the pressure loss coefficient, you need to find the value of the friction factor (f) based on the Reynolds number (Re) and the relative roughness of the steel pipe (ε/D). The Reynolds number is given by: Re = (ρ × V × D) / μ Where: - ρ is the density of the fluid (in units of mass per unit volume, such as lb/ft³ or kg/m³) - V is the velocity of the fluid (in units of velocity, such as ft/s or m/s) - D is the diameter of the pipe (in units of length, such as feet or meters) - μ is the dynamic viscosity of the fluid (in units of force per unit area per unit time, such as lb/ft·s or kg/m·s) Once you have the Reynolds number (Re) and the relative roughness (ε/D), you can use the Moody diagram to find the corresponding friction factor (f). The pressure loss coefficient (K) can then be calculated as: K = f × (L/D) Where: - L is the length of the pipe (in units of length, such as feet or meters) - D is the diameter of the pipe (in units of length, such as feet or meters) By using the Darcy-Weisbach equation and the Moody diagram, you can accurately calculate the pressure loss coefficient for steel pipes, which is essential for designing and analyzing fluid flow systems.

- Q: Can steel pipes be used for underground drainage?

- Yes, steel pipes can be used for underground drainage. Steel pipes are commonly used in underground drainage systems due to their durability, strength, and resistance to various environmental factors. They are able to withstand heavy loads, pressures, and corrosion, making them suitable for long-term underground drainage applications.

- Q: What are the common applications of seamless steel pipes?

- Due to their unique properties, seamless steel pipes are widely used in various industries. Here are some of the most common applications: 1. The oil and gas industry extensively utilizes seamless steel pipes for transporting oil, gas, and other fluids. These pipes are preferred because of their high strength, durability, and resistance to corrosion, making them suitable for harsh environments. 2. Seamless steel pipes are extensively used in construction projects, such as building, bridge, and tunnel construction. They are ideal for structural applications due to their ability to withstand heavy loads and provide excellent strength and stability. 3. The automotive industry relies on seamless steel pipes for manufacturing automotive parts, including exhaust systems, engine components, and hydraulic systems. These pipes offer high strength, reliability, and resistance to heat, making them suitable for demanding automotive applications. 4. Various mechanical and engineering applications benefit from the usage of seamless steel pipes. They are commonly used for carrying fluids, gases, and steam, as well as for transmitting power in machinery and equipment. 5. Power plants extensively utilize seamless steel pipes for transporting steam and hot water. These pipes are capable of withstanding high pressure and temperature, making them ideal for power generation applications. 6. The petrochemical industry heavily relies on seamless steel pipes for transporting chemicals, gases, and liquids. These pipes have excellent resistance to corrosion, which is essential when dealing with hazardous and corrosive substances. 7. The mining industry utilizes seamless steel pipes for various applications, including the transportation of slurry, water, and other mining-related fluids. These pipes offer durability, reliability, and resistance to abrasion, making them suitable for the challenging mining environment. 8. The aerospace industry finds applications for seamless steel pipes in manufacturing aircraft components, such as hydraulic systems, fuel lines, and structural parts. These pipes provide a high strength-to-weight ratio and resistance to extreme temperatures and pressure. Overall, seamless steel pipes play a crucial role in a wide range of industries. Their exceptional properties, including strength, durability, resistance to corrosion and high temperatures, make them an essential component in various industrial processes and infrastructure development.

Send your message to us

Carton Seamless Steel Pipe ASTM A106/API 5L/ASTM A53 GR.B

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords