Building Hoist Single SCD200 Counterweight

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Building Hoist Single SCD200

CounterweightThe P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device, and the composition and function of each major part can be described as below:

1. Metal Structure

The metal frame is composed of: cage, mast, base frame & enclosure, anchorage and etc. The surface of these metal structures can be spray-painted and hot galvanized according to customers’ requirements.

Cage is of the main running & transporting part, whose dimension and shape can be customized according to the factual site condition. Entrance & exit doors can be produced as up & down sliding or ramping model for safety and convenience. Every set of P/M hoist can be equipped with single or double cages. The entrance & exit doors and the wall of the cage can be produced with steel net, perforated steel board or aluminum plastic board. The floor and ceiling parts can be produced with steel board. On the top of the cage, there is a trap door with 0.25 m2, equipped with the limit switches. When testing and repairing, workers can climb up to the top of the cage through the ladder inside the cage. When emergency happens, the trap door can be used as exit. There are hand rails installed on the top of the cage, protecting workers from falling.

In addition, the hoist can be equipped with driving cab and rebar carrier device according to the customers’ requirements.

Main Parts of Building Hoist

1. Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

2. Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process, and ensures automated leveling.

3. Adopts open loop V/Fcontrol; the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoid slipping during downward stopping of hoist.

4. The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the engery consumption and mitigates effects to on site electric equipments.

5. The steadiness during running mitigates concussion to mechanical parts, reduces wears of rack, pinion and the brake and prolongs the spare parts'life.

6. The VF system also has the over voltage protection,low voltage protection, overcurrent, overload and anti-stalling protection functions,

7. The system applies the special software for hoists developed by our company, making the operation more safe and reliable.

Building Hoist images

CMAX Building Hoist

Anchorage System

Driving Unit

Warehouse

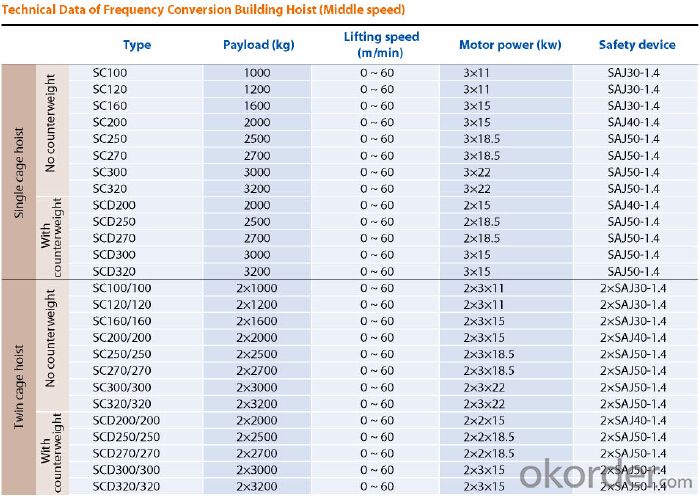

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance & exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: The working principle of construction elevator

- SC type construction lifter is a kind of elevator on the gear, rack drive, is mainly used in high-rise building construction, cargo transportation, the elevator can be very convenient to install and remove; It can increase with the increase of the building. There is a single cage and double cage construction elevator, and the single-cage construction lift can be a double cage lift after adding a cage and other parts. If a heavy device is configured, its payload can be doubled. The SC type construction elevator has a very reliable electrical and mechanical safety system, which is a safe and efficient vertical transportation.

- Q: Can a building hoist be utilized for the transportation of objects within and between buildings?

- <p>Yes, building hoists are specifically designed to move objects vertically within buildings. They are commonly used in construction to lift materials and equipment to different floors. Additionally, they can be employed to transport objects into and out of buildings, especially when access is limited or when heavy loads need to be moved over short vertical distances. However, it's important to adhere to safety guidelines and regulations when operating a building hoist to ensure the secure and efficient movement of objects.</p>

- Q: Is it possible for a single lifting device to simultaneously lift multiple objects with varying weights?

- <p>Yes, a single lifting device can be used to lift multiple objects at once with different weights, provided the total weight does not exceed the device's lifting capacity. The device must be designed to handle the combined weight and ensure even distribution of the load. Safety measures and proper securing of the objects are crucial to prevent accidents. It's important to follow the manufacturer's guidelines and never exceed the maximum load capacity to avoid damage or injury.</p>

- Q: This question asks if a building hoist can be utilized for lifting both light and heavy objects.

- <p>Yes, a building hoist can be used for lifting both light and heavy objects. It is designed to handle a wide range of weights, depending on its capacity. Building hoists are engineered to lift materials such as bricks, concrete, and steel beams during construction. However, it's crucial to ensure that the hoist's lifting capacity is not exceeded to avoid accidents. Always check the manufacturer's specifications and safety guidelines before lifting any object with a building hoist.</p>

- Q: How large a leakage protector is used for the construction elevator

- A leakage switch with a rated current of 100-160a. The rated action current of the second class is 50-75hm. The rated action current is 30-45hm. The action time is less than or equal to 0.1 s. Comply with safety specification according to this construction.

- Q: There are differences between the construction elevator and the construction elevator

- When it comes to the construction elevator, people will immediately think of construction lifter, the construction elevator and elevator is just a different name or have their own respective working principle? By below small make up to you to introduce: construction elevator is often referred to as construction lifter, but construction lifter, including the definition of a broader platform construction also belongs to the construction lifter series.

- Q: Is it possible to use a building hoist for lifting heavy materials that cannot be manually lifted?

- <p>Yes, a building hoist is specifically designed for lifting heavy materials that are too heavy or cumbersome to lift manually. These hoists are engineered to handle significant weight loads and are commonly used in construction settings to move materials such as bricks, cement, and steel beams to various levels of a building. They are an essential tool for safe and efficient material handling in construction projects.</p>

- Q: This question asks for the steps or methods to keep a building hoist in good condition and fix any damages.

- <p>To maintain and repair a damaged building hoist, follow these steps: Regularly inspect the hoist for wear and tear, checking cables, pulleys, and brackets. Lubricate moving parts to reduce friction and prevent rust. Replace damaged or worn-out components promptly. Ensure all safety features are functioning correctly. If a hoist is severely damaged, consult with a professional to assess the damage and perform necessary repairs. Always adhere to the manufacturer's guidelines and safety regulations during maintenance and repair processes.</p>

- Q: This question asks about the safety mechanisms or features that are included in a hydraulic building hoist to ensure its secure operation.

- <p>Hydraulic building hoists are equipped with several safety features to ensure secure operation. These include overload protection to prevent the hoist from lifting more weight than it is designed for, emergency stop buttons for immediate cessation of operations, safety hooks or shackles to secure the load, and lower limit switches to prevent over-lowering. Additionally, they often have a fail-safe valve system that locks the hoist in place if pressure is lost, and a cage or gate to protect operators from falling objects. Regular maintenance and inspection are also crucial for maintaining the safety of these hoists.</p>

- Q: What are the fundamental parts that make up a building hoist?

- <p>The basic components of a building hoist include the hoist machine, mast or tower, guide rails, lifting cage, counterweight system, safety devices, electrical control system, and communication system. The hoist machine powers the lifting and lowering of the cage, while the mast provides structural support. Guide rails ensure the cage moves vertically, and the counterweight balances the cage's weight. Safety devices protect against accidents, and the electrical control system manages operations. The communication system allows for coordination between the hoist operator and other construction personnel.</p>

Send your message to us

Building Hoist Single SCD200 Counterweight

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords