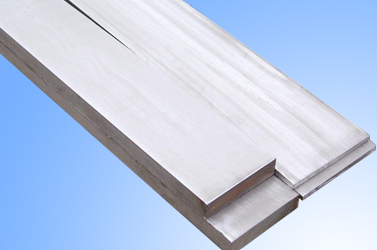

SS400 Q235B hot rolled steel flat bar Slitting flat bar galvanized flat bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 34000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

steel flat bar

steel flat bar thick : 2-20mm

steel flat bar wide : 10-870mm

steel flat bar length : 6m;9m;12m

Hot Rolled Flat Bar/ Slitting Flat Bar

1.We produce all the specifications of hot rolled flat steel and slitting flat bar

2.Lgare quantity in stock.

3.Best service.

flat bar

1.size: 20--150mm *2--20mm a36 flat bar

2.material:Q235 SS400 a36 flat bar

3.width:20-150mm

4.thickness:2--20mm

5.flat steel

1) Size: 2# - 150#

2) steel grade:Q195-Q235, ss400, s235 s275 s355 st37 st52.....

Packing:Suitable for export with hooks for easy unloading of material with bundle weightabout 2MT

Size | Width | Tolerance | Thickness | Tolerance |

20 | 20 | +0.5 -1 | 2--4 | +0.3 -0.5 |

22 | 22 | +0.5 -1 | 2--4 | +0.3 -0.5 |

25 | 25 | +0.5 -1 | 2--6 | +0.3 -0.5 |

28 | 28 | +0.5 -1 | 2--6 | +0.3 -0.5 |

30 | 30 | +0.5 -1 | 2--6 | +0.3 -0.5 |

32 | 32 | +0.5 -1 | 2--6 | +0.3 -0.5 |

35 | 35 | +0.5 -1 | 2--6 | +0.3 -0.5 |

40 | 40 | +0.5 -1 | 36 | +0.3 -0.5 |

45 | 45 | +0.5 -1 | 36 | +0.3 -0.5 |

50 | 50 | +0.5 -1 | 36 | +0.3 -0.5 |

55 | 55 | +0.6 -1.3 | 3--6 | +0.3 -0.5 |

60 | 60 | +0.6 -1.3 | 3--10 | +0.3 -0.5 |

65 | 65 | +0.6 -1.3 | 3--10 | +0.3 -0.5 |

70 | 70 | +0.6 -1.3 | 3--10 | +0.3 -0.5 |

75 | 75 | +0.6 -1.3 | 3--10 | +0.3 -0.5 |

80 | 80 | +0.9 -1.8 | 3--10 | +0.3 -0.5 |

85 | 85 | +0.9 -1.8 | 6--10 | +0.3 -0.5 |

90 | 90 | +0.9 -1.8 | 6--10 | +0.3 -0.5 |

95 | 95 | +0.9 -1.8 | 6--10 | +0.3 -0.5 |

100 | 100 | +0.9 -1.8 | 6--12 | +0.3 -0.5 |

105 | 105 | +1 -2 | 6--12 | +0.3 -0.5 |

110 | 110 | +1 -2 | 6--12 | +0.3 -0.5 |

120 | 120 | +1 -2 | 6--20 | +0.3 -0.5 |

125 | 125 | +1 -2 | 6--20 | +0.3 -0.5 |

130 | 130 | +1 -2 | 6--20 | +0.3 -0.5 |

140 | 140 | +1 -2 | 6--20 | +0.3 -0.5 |

150 | 150 | +1 -2 | 6--20 | +0.3 -0.5 |

- Q:What are the different types of finishes available for steel flat bars?

- There are several types of finishes available for steel flat bars, including hot rolled, cold rolled, galvanized, and polished.

- Q:Can steel flat bars be used for electrical or grounding applications?

- No, steel flat bars are not typically used for electrical or grounding applications. Copper or aluminum are the preferred materials for such purposes, as they offer better conductivity and are less prone to corrosion.

- Q:Can steel flat bars be used for making sculptures?

- Yes, steel flat bars can be used for making sculptures. They are a versatile material that can be easily shaped and welded to create various forms and structures in sculptural works.

- Q:Can steel flat bars be hardened?

- Yes, steel flat bars can be hardened through a heat treatment process called quenching and tempering. This involves heating the steel to a high temperature and then rapidly cooling it in water or oil, which increases its hardness. The hardened steel can then be further tempered to improve its toughness and reduce brittleness.

- Q:How are steel flat bars manufactured?

- Steel flat bars undergo a process called hot rolling to be manufactured. This process entails heating a steel billet or ingot above its recrystallization temperature, usually around 1,000 to 1,300 degrees Celsius. The heated steel is then passed through a series of rollers to gradually decrease its thickness and shape it into a flat bar. In the hot rolling process, the steel is initially descaled to eliminate any surface impurities and oxides. It then goes through a roughing mill, which consists of multiple sets of large rollers that progressively reduce the steel's thickness. The steel is continuously reheated and passed through the rollers until it reaches the desired thickness. Once the steel has reached the desired thickness through roughing, it moves on to a finishing mill. This mill features smaller rollers that further decrease the thickness of the steel and enhance its surface finish. The steel is rolled back and forth between these rollers until it reaches its final thickness, typically ranging from 3 to 25 millimeters. After the final rolling, the steel flat bar is cooled using water or air to temper it and improve its mechanical properties. It is then cut to the desired length and may undergo additional processes like straightening or surface treatments, depending on its intended use. In summary, the manufacturing process of steel flat bars involves hot rolling, which encompasses descaling, roughing, finishing, cooling, and final processing stages to produce flat bars with various thicknesses and lengths.

- Q:Can steel flat bars be used in the manufacturing of conveyor systems?

- Yes, steel flat bars can be used in the manufacturing of conveyor systems. Steel flat bars are commonly utilized for their strength, durability, and versatility, making them suitable for various industrial applications, including conveyor systems. They can be used for constructing frames, supports, guides, or even as conveyor belts in certain cases. Steel flat bars provide stability and can withstand heavy loads, making them an ideal choice for conveyor system manufacturing.

- Q:Can steel flat bars be used for making staircases or ramps?

- Staircases or ramps can indeed be constructed using steel flat bars. Renowned for their robustness and longevity, steel flat bars are an ideal selection for structural applications such as staircases and ramps. They can serve as the primary support structure for the stairs or even function as the treads themselves. By welding or bolting the flat bars together, a stable and secure staircase or ramp can be created. Moreover, steel flat bars can be easily tailored and shaped to accommodate the specific design and requirements of the staircase or ramp. All in all, the strength, durability, and versatility of steel flat bars make them a dependable and widely favored option for the construction of staircases and ramps.

- Q:What is the typical price range for steel flat bars?

- The typical price range for steel flat bars can vary depending on factors such as size, thickness, and the current market conditions. However, as a general guideline, the price range for steel flat bars can range from around $10 to $50 per foot.

- Q:Can steel flat bars be used for manufacturing aerospace components?

- Yes, steel flat bars can be used for manufacturing aerospace components. Steel is a common material used in aerospace manufacturing due to its high strength and durability. Flat bars can be machined, formed, and welded to create various aerospace components such as brackets, supports, and structural elements. However, the specific grade and specifications of the steel should be carefully considered to meet the stringent requirements of the aerospace industry.

- Q:Can steel flat bars be coated with anti-slip materials?

- Yes, steel flat bars can be coated with anti-slip materials.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

SS400 Q235B hot rolled steel flat bar Slitting flat bar galvanized flat bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 34000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords