321 Stainless Steel Sheet price per kg

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Specification:

321 stainless steel price per kg

1.Grade:304,304L,316,316L,309S,310S,904L,etc

2.Finish:2B,BA,HL,Brush,NO.1,NO.4,Mirror and so on.

3.Standards:JIS,AISI,ASTM,GB

4.Thick;0.3mm--150mm

5.Wide;1000mm--2000mm

6.Length;1000mm--6000mm

7.Packing: standard export sea-worthy packing or as the customers’ requirement

8.Payment:L/C and T/T

9.Shipment:about 10 days after payment terms.

10.Trade Terms:FOB Shanghai.

11.Application construction, building, kitchwares, medical industry, eletricity industry and so on.

We have very good connection with factory, so we can provide competitive price to you, if u are intresented in our products, pls feel free to contract us.

Your enquiry will be welcome.

Details:

Type | Stainless steel sheet(cold rolled or hot rolled) |

Thinckness | 0.3mm - 150mm or as customer's requirement |

Widthness | 1000mm - 2000mm or as customer's requirement |

Length | 1000mm - 6000mm or as customer's requirement |

Finish | 2B,BA,HL,Brush,NO.1,NO.4,Mirror and so on. |

Standard | JIAISI, ASTM, GB, |

Material | 304, 304L, 316, 316L, 309S, 310S, 321, etc |

Application range | Foodstuff, Gas, metallurgy, biology, electron, chemical, petroleum,boiler, nuclear energy, Medical equipment, fertilizer etc |

Package | Standard export sea-worthy packing |

Delivery time | About 7 days after the order |

Quality | Prime |

Productivity | 500 tons/week |

Note | Other standards can be produced as the customers’ requirement |

- Q:What is the composition of stainless steel sheets?

- Comprised mainly of iron, chromium, and other elements like nickel, manganese, and carbon, stainless steel sheets possess exceptional strength and durability. Iron, being the primary constituent, imparts resilience and sturdiness to these sheets, whereas chromium is incorporated to enhance their resistance against corrosion. By adding nickel, the sheets' ability to withstand high temperatures is bolstered, along with an improvement in their overall mechanical properties. Manganese is introduced to augment their malleability, while carbon contributes to elevating their hardness. The harmonious collaboration of these elements results in a versatile and remarkably dependable material that finds extensive application across diverse industries, including construction, automotive, and manufacturing.

- Q:How do you prevent chloride-induced corrosion in stainless steel sheets?

- There are various steps that can be taken to prevent corrosion in stainless steel sheets caused by chloride. These include: 1. Selecting the appropriate stainless steel grade that is resistant to chloride corrosion. Grades like 316 or 317 are particularly effective in resisting chloride attack. 2. Enhancing the resistance to chloride-induced corrosion by applying a passivation treatment to the stainless steel sheets. This treatment eliminates any surface iron contamination that might have occurred during fabrication and restores the protective oxide layer. 3. Ensuring proper cleaning of the stainless steel sheets on a regular basis to eliminate any chloride-containing contaminants that might have accumulated on the surface. It is important to maintain a clean surface as chloride ions can accumulate from sources like saltwater or cleaning products. 4. Minimizing contact with substances that contain chloride to significantly reduce the risk of corrosion. This involves avoiding direct contact with saltwater, cleaning agents that contain chloride, as well as chloride-rich environments such as swimming pools or coastal areas. 5. Taking design considerations into account in environments where chloride exposure is expected. This can involve using protective coatings, minimizing crevices or gaps where chlorides can accumulate, and ensuring proper drainage to prevent stagnant conditions. 6. Regularly inspecting and maintaining the stainless steel sheets to identify and address any potential corrosion issues before they worsen. This may include repairing surface damage, reapplying passivation treatments if necessary, and keeping the surface clean. By following these preventive measures, the risk of chloride-induced corrosion in stainless steel sheets can be significantly reduced, ensuring their long-term durability and performance.

- Q:How do you remove rust or corrosion from stainless steel sheets?

- To remove rust or corrosion from stainless steel sheets, you can follow these steps: 1. Start by cleaning the surface of the stainless steel sheet with a mild detergent and warm water. This will remove any dirt or grease that could potentially interfere with the rust removal process. 2. After cleaning, thoroughly dry the sheet to prevent any further water damage and to ensure the rust removal process is effective. 3. Next, use a non-abrasive scrubbing pad or a soft cloth to apply a stainless steel cleaner or a homemade solution made of equal parts vinegar and water. Gently rub the affected area in the direction of the grain of the stainless steel. 4. If the rust or corrosion persists, you can try using a paste made of baking soda and water or a mixture of cream of tartar and water. Apply this paste to the affected area and let it sit for about 15 minutes. Then, scrub the area gently with a soft cloth or a non-abrasive scrubbing pad. 5. If the above methods do not fully remove the rust or corrosion, you can try using a commercial rust remover specifically designed for stainless steel. Be sure to follow the instructions provided by the manufacturer and use appropriate safety precautions. 6. After removing the rust or corrosion, rinse the stainless steel sheet thoroughly with clean water and dry it completely to prevent any water spots or further damage. 7. To prevent future rust or corrosion, it is recommended to regularly clean and maintain stainless steel surfaces using non-abrasive cleaners and avoiding harsh chemicals or abrasive materials. Remember to always test any cleaning solution or rust remover on a small, inconspicuous area of the stainless steel sheet before applying it to the entire surface, to ensure it doesn't cause any damage or discoloration.

- Q:Can stainless steel sheets be used for elevator handrails or grab bars?

- Stainless steel sheets are indeed suitable for elevator handrails or grab bars. These applications often favor stainless steel due to its commendable durability, resistance to corrosion, and pleasing appearance. One can fashion stainless steel sheets into different forms and dimensions to meet the precise demands of elevator handrails or grab bars, guaranteeing the safety and comfort of users. Moreover, stainless steel is effortlessly cleaned and maintained, making it a logical preference for frequently-used spaces like elevators.

- Q:What is the hardness of stainless steel sheets?

- The hardness of stainless steel sheets can vary based on the specific grade and manufacturing process employed. Typically, stainless steel sheets are renowned for their exceptional hardness and strength. In industrial applications, the most commonly utilized grades, such as 304 and 316, exhibit a hardness range of 70-90 HRB (Rockwell hardness B scale) or 150-200 HV (Vickers hardness). However, there are also specialized stainless steel alloys available that can possess even higher degrees of hardness, such as precipitation-hardened grades like 17-4 PH, which can attain hardness levels of 30-40 HRC (Rockwell hardness C scale). To determine the precise hardness of a particular stainless steel sheet, reference to the manufacturer's specifications or performing hardness testing utilizing appropriate methods and equipment is necessary.

- Q:Are stainless steel sheets suitable for high-temperature applications?

- Yes, stainless steel sheets are suitable for high-temperature applications. Stainless steel is known for its excellent heat resistance properties, making it an ideal material for use in high-temperature environments. It can withstand extreme heat without losing its strength or structural integrity, making it highly durable and reliable. Stainless steel sheets are often used in industries such as aerospace, automotive, and manufacturing, where high temperatures are common. Additionally, stainless steel sheets have low thermal expansion, which means they can maintain their shape and dimensions even when exposed to fluctuating temperatures. This makes stainless steel sheets a preferred choice for applications where dimensional stability is crucial. Overall, stainless steel sheets are a suitable option for high-temperature applications due to their exceptional heat resistance, durability, and dimensional stability.

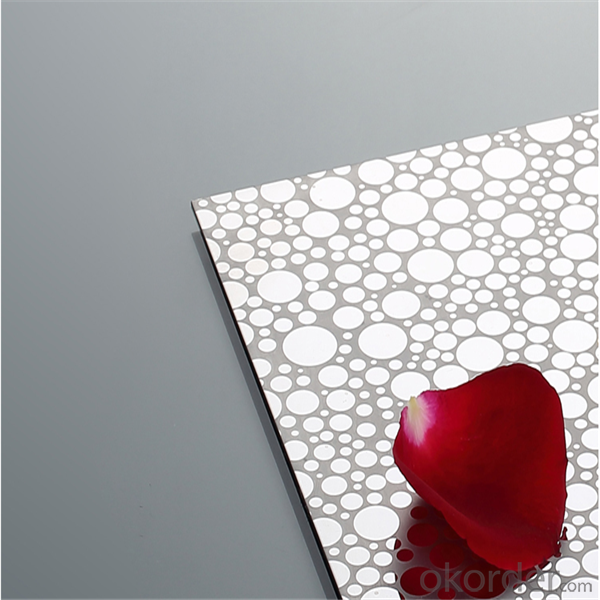

- Q:What are the different types of perforated patterns available for stainless steel sheets?

- There are several different types of perforated patterns available for stainless steel sheets, including round, square, slotted, and decorative patterns. Each pattern offers a unique aesthetic appeal and functional characteristics, making it suitable for various applications.

- Q:Can stainless steel sheets be used for sink fabrication?

- Yes, stainless steel sheets can be used for sink fabrication. Stainless steel is a durable and corrosion-resistant material that is commonly used for sinks due to its hygienic properties and ease of cleaning.

- Q:How do you cut stainless steel sheets?

- Cutting stainless steel sheets can be done using different methods, depending on the thickness of the sheet and the desired precision of the cut. Here are a few common techniques: 1. Manual cutting: For thinner stainless steel sheets (up to around 16 gauge), you can use a handheld shear or tin snips. These tools allow you to cut straight lines or curves by applying pressure and cutting through the sheet. However, this method may not be suitable for thicker sheets as it can be labor-intensive and produce rough edges. 2. Power shears: For thicker stainless steel sheets, power shears or electric nibblers are more effective. These tools use a sharp cutting blade or punch to make straight or curved cuts. They provide more precision and require less effort compared to manual cutting methods. 3. Circular saw: A circular saw with a carbide-tipped blade designed for cutting metal can also be used to cut stainless steel sheets. This method is suitable for thicker sheets and allows for straight cuts. However, it may produce more noise, sparks, and heat, so proper safety measures such as wearing protective goggles and gloves should be taken. 4. Plasma cutting: For industrial or heavy-duty applications, plasma cutting is commonly used. This method involves using a high-temperature plasma jet to melt through the stainless steel sheet, creating a precise and clean cut. Plasma cutting machines are expensive and require specialized training to operate. Regardless of the method, it is important to take safety precautions when cutting stainless steel sheets. Always wear protective gear, such as safety glasses, gloves, and a dust mask, to protect yourself from metal shards, sparks, and dust. Additionally, ensure that the sheet is securely clamped or supported to prevent it from moving during the cutting process.

- Q:Are stainless steel sheets suitable for medical equipment?

- Indeed, medical equipment can be fabricated using stainless steel sheets. The utilization of stainless steel in medical equipment is widely favored due to its remarkable resistance to corrosion and its ability to endure. It boasts effortless cleaning and sterilization, rendering it fitting for employment in healthcare facilities where cleanliness and hygiene are paramount. Furthermore, the high strength-to-weight ratio of stainless steel permits the creation of lightweight yet robust medical equipment. Moreover, its magnetic permeability is low, rendering it an ideal option for situations necessitating minimal electromagnetic interference. All in all, stainless steel sheets are a dependable and pragmatic selection for the production of medical equipment.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

321 Stainless Steel Sheet price per kg

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords