Bosch Profiles Aluminum A380 High Quality Die Cast

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of A380 Aluminum Die Cast Description:

These are used when the casting alloy cannot be used in hot-chamber machines; these include aluminium, zinc alloys with a large composition of aluminium, magnesium and copper. The process for these machines start with melting the metal in a separate furnace. Then a precise amount of molten metal is transported to the cold-chamber machine where it is fed into an unheated shot chamber (or injection cylinder). This shot is then driven into the die by a hydraulic or mechanical piston. The biggest disadvantage of this system is the slower cycle time due to the need to transfer the molten metal from the furnace to the cold-chamber machine.

2.Main Features of the A380 Aluminum Die Cast:

Drawing: provide by customer, or we design as the sample.

Mold: Design and produce by ourself.

Product Material Option: A360, A380, ADC12, ADC3, AlsSi7Mg, AlSi12, AlSi9Cu3, etc.

SURFACE TREATMENT

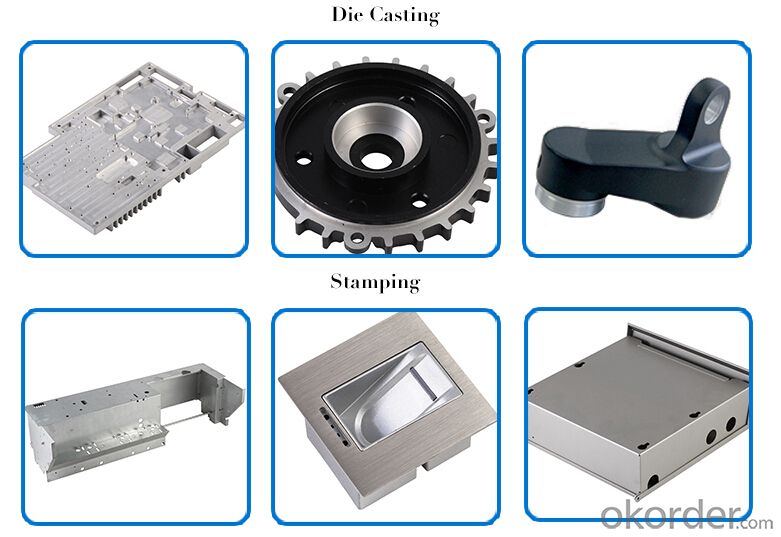

3. A380 Aluminum Die Cast Images

4. A380 Aluminum Die Cast Specification

Process | Material Grade | Weight range | Application |

Investment casting, sand casting, ESR casting Die casting Metal casting

| Iron: Grey iron, Ductile iron Steel: Carbon steel, Alloy steel, Stainless steel Nonferrous metal: Bronze, Brass, Al, Zinc, Ti, etc. | From 0.01Kg to 100 ton | Auto motive, agricultural machines, vessels, toolings, mining , oi l& gas machinery, locomotive industry, aerospace, hardware, contruction, engineering machinery, electrical equipment etc. |

5. RFQ

1).What kind of the materials can be provided?

Product Materials: mainly is Aluminum alloy. But we also can provide other material products for you: like zinc alloy, iron, stainless steel, plastic. Because we are very familiar with them, and better service for you

Mould Materials: H13,3Cr2W8V,4Cr5MoVlsi,SKD61,8407#

According to customers’ requirement

2).What your payment terms?

TT or LC

3).What is the privacy policy of your company?

We respect for all the customers, and make all the customers information confidential. We limit the scope of the information provided to third parties, and we allow its use only the customer permits.

- Q: How do I choose the right aluminum profile for my project?

- When choosing the right aluminum profile for your project, consider factors such as the desired strength and durability, the specific dimensions and shape required, the intended application or purpose, and any particular aesthetic or design preferences. It is also important to evaluate the compatibility of the chosen profile with other components or materials that will be used in your project. Research and consultation with experts or suppliers can provide valuable insights and guidance in making an informed decision.

- Q: What is the cost of aluminum profiles?

- The cost of aluminum profiles can vary depending on several factors such as the type of profile, the length and thickness required, and the market conditions. Generally, aluminum profiles are priced per linear foot or meter. Additionally, the price may also be influenced by the quality of the aluminum used and any additional finishes or treatments required. It is advisable to contact local suppliers or manufacturers for specific pricing information as it can differ from region to region.

- Q: This question asks for methods to protect aluminum profiles from water damage during the installation and usage phases.

- <p>To prevent water damage to aluminum profiles during installation or use, follow these steps: 1. Ensure the aluminum profiles are properly sealed with a high-quality sealant to prevent water penetration. 2. Use corrosion-resistant fasteners and hardware to avoid rusting. 3. Install drainage systems to direct water away from the profiles. 4. Regularly inspect and maintain the profiles to identify and repair any damage promptly. 5. Avoid installing profiles in areas with high humidity or direct exposure to rain. 6. Use protective coatings or paints that are water-resistant and compatible with aluminum. 7. Keep the profiles clean and free from dirt or debris that can trap moisture. By following these precautions, you can significantly reduce the risk of water damage to aluminum profiles.</p>

- Q: Can aluminum profiles cross Luo? Why is the appearance of an aluminum profile component of a Japanese original machine extremely close to that of Luo Luo? Why? Why?

- The company since its establishment, relying on preferential policies, the local government to adhere to the people-oriented, development of the concept of Societe Generale, seek survival by quality, rely on the brand to expand the market, seize the opportunity, innovation, build a pragmatic and efficient, solidarity of the modern enterprise team.Luoyang is located in the Central Plains, is a famous industrial base, its energy and resource advantages, a strong industrial base, research institutes everywhere, has created favorable conditions for the development of the aluminum industry of new and high technology, coupled with the current domestic and foreign aluminum demand is far greater than the output of this special factors, provides a good opportunity for the more the project, the project prospects for a broader market.

- Q: 80 series insulation aluminum broken bridge 1.4 thick, one square kilogram, how many kilograms aluminum material?

- Each brand of profiles, aluminum weight is not the same, but within the unit area is about 8 kilograms, little difference

- Q: How can I control the hardness of 6063 aluminum profile at 6-9 degrees?

- Classification: extension material, non heat treatment alloy and heat treatment alloy1.1 non heat treated alloys: pure aluminum - 1000 series, Al Mn alloy - 3000 series, Al Si alloy - 4000 series, Al Mg alloy - 5000 Series1.2 heat treatment of Al Cu Mg alloy alloy: 2000, aluminum magnesium silicon alloy - 6000 series aluminium zinc magnesium alloy - 7000.Two, alloy number: China's current general is the American Aluminum Association "Aluminium Association" numberExamples are as follows: 1070-H14 (pure aluminum)2017-T4 (heat treatment alloy)3004-H32 (non heat treated alloy)2.1 first digit: indicates the main addition of alloying elements1: pure aluminum2: the main alloy element added copper3: the main alloying elements are manganese or manganese and magnesium4: the main alloy element is added silicon5: the main alloying element is magnesium6: mainly add alloy elements for silicon and magnesium7: the main alloying elements are zinc and magnesium8: a new alloy that does not belong to the above alloy series2.2, second digits: an alloy that indicates the addition of alloying elements or impurities in the original alloy0: table alloy1: table original alloy by the first amendment2: table original alloy after second modifications2.3, third, and four digits:Pure aluminum: represents the original alloyAlloy: the designation of individual alloys"- >: the back of Hn or Tn indicates the condition of work hardening or the symbol of heat treatment state-Hn: indicating the symbol for non heat treated alloys-Tn: a symbol for heat treatment alloysHeat treatment of 2 aluminium and aluminium alloyA chain symbol: if the alloy element is added, it is not enough to meet the requirements, but still needs cold processing, quenching and agingTreatment and soft burning to obtain the required strength and performanceAs a result of quenching and tempering, the result of quenching and tempering is chain

- Q: How do aluminum profiles perform in terms of sound insulation?

- Compared to materials like wood or uPVC, aluminum profiles generally do not have good sound insulation properties. This is because aluminum is lightweight and thin, allowing sound waves to easily pass through. Furthermore, aluminum profiles often have a hollow structure, which further reduces their ability to block or absorb sound. It is important to consider that the overall sound insulation performance of a window or door system depends on various factors. These include the thickness of the glass, the quality of the seals, and the installation method. To improve the sound insulation capabilities of aluminum profiles, manufacturers may incorporate additional features such as double or triple glazing, laminated glass, or acoustic seals. In conclusion, while aluminum profiles alone may not offer optimal sound insulation, their performance can be enhanced by combining them with other elements. If sound insulation is a major concern, it is advisable to explore alternative materials that inherently provide better sound insulation properties.

- Q: Are aluminum profiles resistant to chemicals and acids?

- Yes, aluminum profiles are generally resistant to chemicals and acids due to their natural oxide layer that provides a protective barrier against corrosion. However, certain highly corrosive chemicals or acids may still cause damage over time.

- Q: What are the different bending machines or tools used for aluminum profiles?

- Aluminum profiles can be shaped and angled using various bending machines and tools. These tools are designed to meet specific project requirements, manipulating the profiles in different ways. 1. For smaller aluminum profiles, the Manual Tube Bender is a hand-operated bending tool. It consists of a lever and a bending shoe, allowing for manual bending of the profile. 2. When dealing with larger and thicker aluminum profiles, the Hydraulic Tube Bender is equipped with hydraulic power. This machine offers greater precision and control, making it ideal for industrial applications. 3. The CNC Tube Bending Machine is a computer-controlled machine that combines hydraulic power and computer programming. With this machine, aluminum profiles can be accurately bent, making it suitable for high-volume production and intricate designs. 4. The Roll Bending Machine is specifically designed for bending aluminum profiles into curved shapes. It uses three rolls, with the profile passing through the middle roll while the other two rolls apply pressure to achieve the desired curve. 5. To bend aluminum profiles without deforming or collapsing the inner diameter, the Mandrel Bender is used. This tool utilizes a mandrel inserted into the profile to support the inner wall during the bending process. 6. The Rotary Draw Bender is a machine that produces accurate and repeatable bends in aluminum profiles. It uses bending dies and a rotating arm, commonly used for tubes and pipes, but can also be adapted for aluminum profiles. These bending machines and tools offer various levels of precision, control, and production capacity. Manufacturers and fabricators can select the most suitable option based on their specific needs and requirements.

- Q: or what is the difference between the national standard aluminum profile and the European standard aluminum profile, preferably with pictures? Thank you

- The difference between national standard aluminum profile and European standard aluminum profile:Cross section four angles are different: national standard, four angles are right angle, European standard four angles have radian;The shape of the groove is not the same: GB groove is square, European standard slot is obtrapezoid;The rice is different in weight: the national standard is relatively heavy, and the European standard is relatively light.The fittings and installation methods used are different.

Send your message to us

Bosch Profiles Aluminum A380 High Quality Die Cast

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords