Black Plastic Nursery Plug Trays Cell Seed Tray of 32 200 288

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

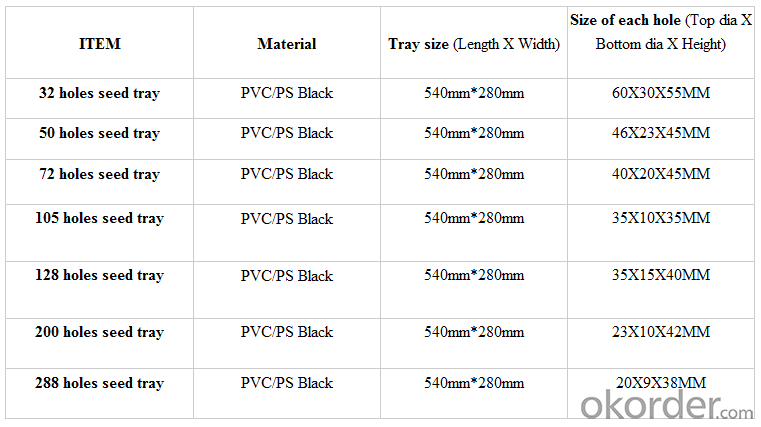

Specification of Plug Trays HIPS Made Plastic Plug Tray for Greenhouse (Growing and Seedling):

Features of Plug Trays HIPS Made Plastic Plug Tray for Greenhouse (Growing and Seedling):

· Material: HIPS

· Thickness: 0.5mm-1.5mm, Standard:1mm

· Weight: 80g(±5)g-230g(±5)g, Standard weight:155g(±5)g

· Size: length:490mm-540mm, width:190mm-345mm,depth:25mm-150mm

· Standard:540mmX280mm

· Cell count: 18-512

· Package: In Carton

· Warrenty: 8-10 times

Packaging & Delivery

Packing Detail: export standard carton or large bags

Delivery time: 4 million per momth after receipt of deposit

Advantage:

Waterproof, UV-resistant, extrusion-resistant

Easy carry for young seeding plant and grow

Service:

1. Quick, efficient and professional response within 24 hours, 14 hours online services

2. 10 years manufacturing and exporting experience in agriculture field.

3. Technical support and solution by chief engineer.

4. Strict quality control system & team, high reputation in the market.

5. Full range of irrigation products for choice

6. OEM/ODM services

7. Accept sample order before Mass Order

Picture of Plug Trays HIPS Made Plastic Plug Tray for Greenhouse (Growing and Seedling):

FAQ of Plug Trays HIPS Made Plastic Plug Tray for Greenhouse (Growing and Seedling):

Q: 1.How long is the production time?

A: Usually one to two weeks.

Q: 2.How is the seed tray being packaged?

A: They can be packaged in carton or pallets. Carton size is 1375px*725px*1250px.

Q:3.How many times can the seed tray be used?

A: Under the same environment, it is decided by the thickness. Usually 0.6mm thickness can be used for 1 or 2 times.

1.0 thickness can be used for 3-4 times. 1.5 thickness can be used for 8-10 times.

- Q: I have been doing a science experiment for clas,s and have seen if mushrooms last longer in paper or plastic bags. After doing the assignment. The mushrooms kept in the plastic fresh seel bags have lasted longer. HELP ME if my experiment wrong or right.P.S i used the plastic bags with the seel on top its makes vegetables last longer. am i right or wrong?

- Its an experiment so there is no right or wrong answer simply a result. Its generally thought that mushrooms keep in paper last longer as the bags absorb the excess moisture but your experiment has suggested otherwise.

- Q: How do agricultural plastic products help with moisture retention?

- Agricultural plastic products, such as mulch films and drip irrigation tubing, help with moisture retention by creating a barrier between the soil and the external environment. This barrier prevents excessive evaporation of water from the soil, keeping moisture levels more consistent and reducing water loss. Additionally, plastic mulches can help control weed growth, reducing competition for water resources and further enhancing moisture retention in the soil.

- Q: What are some ground cover options for a rooftop courtyard?

- Some ground cover options for a rooftop courtyard include sedum, moss, creeping thyme, creeping Jenny, and succulents. These plants are low-growing, drought-tolerant, and can thrive in shallow soil or containers. They provide greenery, help to reduce heat, and require minimal maintenance.

- Q: This question asks if farmers can employ agricultural plastics to decrease energy consumption within their irrigation systems.

- <p>Yes, farmers can use agricultural plastics to reduce energy usage in their irrigation systems. By employing plastic mulches or drip irrigation systems with plastic tubing, they can minimize water evaporation and ensure more precise water delivery, which can lead to significant energy savings. Plastic mulches can also help retain soil moisture and warmth, reducing the need for additional heating or watering. Additionally, plastic greenhouses can create a controlled environment that conserves energy by retaining heat, thus reducing the need for artificial heating.</p>

- Q: How does plastic rainwater collection system help in water conservation?

- A plastic rainwater collection system helps in water conservation by efficiently capturing and storing rainwater that would otherwise go to waste. This collected water can be used for various non-potable purposes such as watering plants, washing cars, or flushing toilets, reducing the reliance on freshwater sources and minimizing the strain on water supplies.

- Q: Are there any ground cover plants that are suitable for full sun?

- Yes, there are several ground cover plants that are suitable for full sun conditions. Some popular options include creeping thyme, sedum, creeping phlox, and ice plant. These plants are specifically adapted to thrive in direct sunlight and can provide attractive coverage for open areas in your garden.

- Q: How do agricultural plastic products help with seed protection from pests?

- Agricultural plastic products help with seed protection from pests by creating a physical barrier that prevents pests from accessing the seeds. This plastic covering acts as a shield, keeping insects, birds, and other pests away from the seeds, reducing the risk of damage or loss. Additionally, agricultural plastic products can be treated with insecticides or repellents, further enhancing seed protection against pests.

- Q: sorry but i melted little plastic on top of my toaster oven earler and how do I clean it off. its brand new. I only had it for a month.it plastic from out coffee fileters. please tell me.

- Hi okorder

- Q: Can nursery trays be used for starting medicinal herb seeds?

- Yes, nursery trays can be used for starting medicinal herb seeds. Nursery trays are often used for seed starting because they provide a controlled and protected environment for the seeds to germinate and grow. They offer proper drainage and allow for easy transplantation once the seedlings are ready. However, it's important to ensure that the trays are clean and sterile to prevent any diseases or pests from affecting the seedlings.

- Q: does anyone out there that has patterns for plastic canvas we can swap and trade

- I have at least 27 plastic canvas patterns books that I was selling at a stuff sale if you are interested. Many from Needlecraft Shop, Annies Attic. Email me for details. Also have Avon collectables.

Send your message to us

Black Plastic Nursery Plug Trays Cell Seed Tray of 32 200 288

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords