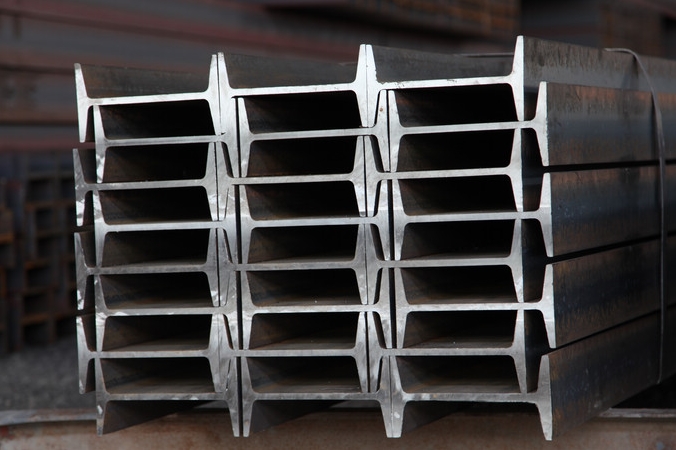

black galvanized steel i beam ipe steel beam

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

We supply ms equal & unequal angle bar, channel bar,jis channel, upn, steel i beam,h beam, ipe, ipeaa, steel sheet pile, flat bar, hollow section, tmt bar, wire rod, binding wire, wire mesh, hrc, CRC, gi coil, ppgi, roofing sheet, chequered coil & plates, medium plate, scaffolding systems, prefabricated container houses etc. Also for metal & steel processing.

If you are in the market for any steel products, please feel free to contact us.

Steel I Beams are widely used throughout the construction industry when supporting heavy loads is required. Commonly termed an “I” Beam because of its shape, beams provide great load bearing support when used horizontally or standing as columns. Available in two configurations, the most popular being the Wide Flange Steel Beam aka H Beam or W Beam with non-tapered flanges. This beam shape has a wider profile for added horizontal strength, making it ideal for skyscrapers or as a house beam, along with bridge beams, trailers, platforms, etc. Standard American Beams, aka Junior Beams or S Beams, have tapered flanges for added strength when your load is concentrated on the flanges, such as machine bases, hoists, cranes or a trolley beam for your garage. Rcjs steel stocks a wide range of steel beam sizes for thousands of applications. Shop online for standard or cut to size lengths at wholesale steel beam prices. We also offer a selection of Galvanized Steel Beams. Just give us a call if you need something special.

- Q: Can Steel I-Beams be used for overhead conveyor systems?

- Yes, steel I-beams can certainly be used for overhead conveyor systems. Steel I-beams are known for their strength and durability, making them an excellent choice for supporting heavy loads in various applications. When used in overhead conveyor systems, they provide a strong and stable framework for the conveyor track to be attached to, ensuring smooth and efficient material handling. Additionally, steel I-beams can be easily customized to meet specific project requirements, such as length, width, and load capacity. Overall, steel I-beams are a reliable and popular choice for overhead conveyor systems due to their strength, versatility, and ability to handle heavy loads.

- Q: What are the common sizes of steel I-beams used in construction?

- The common sizes of steel I-beams used in construction vary depending on the specific application and load requirements. However, some commonly used sizes include 3", 4", 5", 6", 8", 10", and 12" beam depths. The flange width can range from 2" to 8", and the weight per foot can vary from 4.7 lbs to 65 lbs.

- Q: Can steel I-beams be used for long-span structures?

- Long-span structures can indeed utilize steel I-beams. Renowned for their robustness and capacity to bear substantial loads, steel I-beams prove fitting for long-span structures like bridges, industrial edifices, and expansive commercial spaces. The incorporation of steel I-beams enables the development of unobstructed and roomy areas without necessitating intermediate supports. Moreover, steel I-beams facilitate effortless connection and fabrication for extended spans, thus affording flexibility in both design and construction. The elevated strength-to-weight ratio of steel further establishes it as the favored choice for long-span structures, permitting lighter constructions while maintaining unwavering strength and stability. Ultimately, owing to their endurance, strength, and adaptability, steel I-beams enjoy extensive employment within the construction sector for long-span structures.

- Q: Can steel I-beams be used for retail or commercial storefronts?

- Steel I-beams are suitable for retail or commercial storefronts. They are frequently used in commercial construction because of their strength and durability. These beams can handle heavy loads and ensure the building's structural integrity. Furthermore, steel I-beams offer the advantage of design flexibility, enabling spacious storefronts with minimal obstructions. Their ability to withstand strong winds and resist fire makes them a popular option for retail or commercial applications. Additionally, integrating steel I-beams with other materials like glass or masonry allows for visually pleasing storefront designs. In conclusion, steel I-beams are an excellent choice for retail or commercial storefronts as they provide both structural support and architectural appeal.

- Q: What are the considerations for acoustical isolation when using steel I-beams?

- When using steel I-beams for acoustical isolation, some important considerations include the thickness and composition of the I-beams, as well as their connection points and overall structural design. The thickness of the I-beams plays a crucial role in minimizing sound transmission, with thicker beams typically providing better acoustical isolation. Additionally, the composition of the beams, such as the presence of insulation or sound-deadening materials, can further enhance their ability to reduce noise transfer. Proper connection points and structural design are also essential to ensure that vibrations and sound waves are not easily transmitted through the beams, potentially compromising the acoustical isolation.

- Q: How do steel I-beams perform in extreme temperature conditions?

- Steel I-beams perform well in extreme temperature conditions. Due to their high thermal conductivity and low coefficient of thermal expansion, they can efficiently dissipate heat and resist deformation caused by temperature fluctuations. This makes them ideal for use in structures that are exposed to extreme heat or cold, such as industrial buildings, bridges, and high-rise constructions.

- Q: Can steel I-beams be used in the construction of theaters and performance venues?

- Certainly! The utilization of steel I-beams is viable for the construction of theaters and performance venues. These beams are widely employed in construction ventures owing to their strength, durability, and versatility. They are particularly well-suited for expansive structures, like theaters and performance venues, where extensive spans are necessary to accommodate open spaces and unobstructed views for the audience. Steel I-beams possess the capability to endure heavy loads and offer structural stability, thus making them ideal for supporting the weight of large lighting rigs, sound systems, and other equipment utilized in theaters and performance venues. Moreover, steel I-beams can be easily fabricated and customized to meet the specific design prerequisites of the project, allowing for flexibility in the overall architectural design. Overall, the use of steel I-beams proves to be an exceptional choice for the construction of theaters and performance venues, ensuring safety, efficiency, and an aesthetically pleasing environment for audiences to relish.

- Q: Can steel I-beams be used for religious buildings?

- Yes, steel I-beams can certainly be used for religious buildings. Steel is a versatile and durable material that offers numerous advantages in construction, including its strength, load-bearing capabilities, and resistance to fire and corrosion. These qualities make steel I-beams an ideal choice for supporting the structural framework of religious buildings, such as churches, temples, mosques, or synagogues. Steel I-beams provide the necessary structural integrity to support the weight of the building, including the roof and any additional floors. They can span long distances, allowing for open and spacious interior designs, which are often desirable in religious buildings to accommodate large gatherings and create a sense of awe and reverence. Furthermore, steel's fire-resistant properties offer an added level of safety, which is crucial in religious buildings where large crowds may gather. The material's resistance to corrosion also ensures the longevity and durability of the structure, reducing maintenance costs over time. Moreover, steel's versatility allows for creative architectural designs, enabling the construction of religious buildings that can reflect the cultural or spiritual aspects of a particular faith. Steel I-beams can be easily incorporated into both traditional and contemporary architectural styles, providing flexibility in design choices. In conclusion, steel I-beams are certainly suitable for religious buildings due to their strength, durability, fire resistance, and versatility. They provide the necessary structural support while allowing for spacious and architecturally appealing designs that cater to the needs and aesthetic preferences of various faith communities.

- Q: Can steel I-beams be used in sustainable or green building practices?

- Yes, steel I-beams can be used in sustainable or green building practices. Steel is a highly sustainable material as it is 100% recyclable and can be reused indefinitely without losing its properties. Additionally, steel I-beams are durable, energy-efficient, and can support the construction of large, open spaces, reducing the need for additional materials. Furthermore, steel manufacturing processes have become more environmentally friendly, with reduced energy consumption and emissions. Therefore, incorporating steel I-beams in building projects aligns with sustainable and green building practices.

- Q: Can steel I-beams be used in historical preservation or restoration projects?

- Yes, steel I-beams can be used in historical preservation or restoration projects. However, it is important to ensure that their use aligns with the historical significance and aesthetic of the building or structure being preserved. In some cases, steel I-beams can be concealed or integrated in a way that maintains the architectural integrity of the historical structure.

Send your message to us

black galvanized steel i beam ipe steel beam

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products