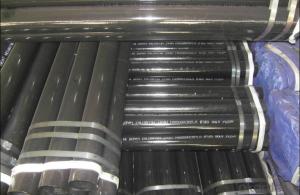

Black ASTM A106 Gr.B Sch40 seamless steel pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Thickness: | 2.5 - 80 mm | Section Shape: | Round | Outer Diameter: | 21.3 - 610 mm |

| Place of Origin: | China (Mainland) | Secondary Or Not: | Non-secondary | Application: | Structure Pipe |

| Technique: | Hot Rolled | Certification: | API | Special Pipe: | Thick Wall Pipe |

| Alloy Or Not: | Non-alloy | Grade: | 20#,45#,16Mn,10#-45# | Standard: | GB/T 8163-1999,GB/T 8162-1999,ASTM A106-2006,API 5CT,GB,ASTM,API |

Packaging & Delivery

| Packaging Detail: | In bundles or as you demand. |

| Delivery Detail: | As fast as we can. |

Specifications

1. sizes range: 21.3-610mm

2. Standard: ASTM A106 Gr.B/API

3. API ,ISO CERTIFICATE APPROVED

4. 80000TONS STOCK PIPES.

| Grade: 20#, 45#, 16Mn, 27SiMn | Thickness: 7 - 45 mm | Section Shape: Round |

| Outer Diameter: 133 - 325 mm | Place of Origin: Liaochen China (Mainland) | Secondary Or Not: Non-secondary |

| Application: Structure Pipe Fluid Pipe Petroleum casing pipe | Technique:Hot Rolled | Certification: API |

| Alloy Or Not: Non-alloy | technology: seamless | material: ASTM A 106 Q 345 ... |

Packaging & Delivery

| Packaging Detail: | seaworthy wooden cases/steel framed cases/simple packing/as customer request |

| Delivery Detail: | according to customer demand,the earliest time is 10days |

Specifications

ASTM A 106 Gr.B seamless carbon steel pipe

Material: ASTM A 106 .GB 8162 8163 API5CT

Package:oil coating&in bundles

Product name | ASTM A 106 Gr.B seamless carbon steel pipe |

Standard | GB ASTM |

Thickness | 2.5-80mm |

Outer diameter | 21.3-610 mm |

Length | 5.8m 6m 12m or as customer demand |

Used area | Petroleum,chemical,power, gas, water, metallurgy, shipbuilding, construction , etc Or as customer demand |

Package | In bundles. Ends can be beveled or square cut, End capped |

Certification | ISO9001.2000, , API, Mill Test Certificate |

Thirdparty inspection | SGS, or as customer demand |

Remark | We can customer made for special requirement |

- Q: How are steel pipes used in the construction of dams and water reservoirs?

- Steel pipes are commonly used in the construction of dams and water reservoirs due to their durability, strength, and ability to withstand high pressure and heavy loads. These pipes are utilized in various important aspects of dam and reservoir construction. One of the main uses of steel pipes in these structures is for the transportation of water. Steel pipes are used to convey water from the source, such as a river or stream, to the reservoir or dam. These pipes are designed to withstand the high water pressure and ensure that there is a continuous flow of water to the reservoir. The durability of steel pipes allows them to remain intact even in harsh conditions and environments. In addition to transporting water, steel pipes are also used for drainage purposes. They are used to create drainage systems that help regulate the water level in the reservoir or dam. These pipes are strategically placed to control the flow of water and prevent any potential flooding or overflow. Steel pipes are also used in the construction of the spillways and outlets in dams and reservoirs. Spillways are designed to release excess water from the reservoir during heavy rainfall or when the water level is too high. Steel pipes are used in the construction of these spillways to provide a controlled path for the water to flow out of the reservoir, preventing any damage to the dam or surrounding areas. Furthermore, steel pipes are utilized in the construction of penstocks, which are large pipes that transport water from the reservoir to the turbines in a hydropower plant. The pressure generated by the water in these pipes is used to drive the turbines and generate electricity. The strength and durability of steel pipes are crucial for ensuring the smooth and efficient operation of hydropower plants. Overall, steel pipes play a vital role in the construction of dams and water reservoirs. Their durability, strength, and ability to withstand high pressure make them an ideal choice for various aspects of these structures, including water transportation, drainage systems, spillways, and penstocks.

- Q: Does seamless steel tube have a bend of 135 degrees?

- In engineering, it is usually marked as "45 elbow" and has no "135" mark. The angle of the elbow is acute, so there will be no more than 90 degrees elbow.Elbow is a common connecting pipe used in plumbing and heating. It is used for the connection of the bend of pipe, and is used to change the direction of pipe.

- Q: How do you transport steel pipes safely?

- Steel pipes can be transported safely by properly securing them using appropriate restraints, such as straps or chains, to prevent shifting or movement during transit. Additionally, using suitable equipment and vehicles, such as flatbed trucks or trailers, with adequate support and cushioning, can help ensure the safe transportation of steel pipes. Regular inspections of the securing arrangements and adherence to relevant safety regulations are also crucial to maintain the safe transport of steel pipes.

- Q: What is the difference between internal and external coating of steel pipes?

- The main difference between internal and external coating of steel pipes is their purpose and the materials used. The internal coating is applied to the inside surface of the pipe to protect it from corrosion, erosion, and chemical reactions with the transported fluids. It is typically made of materials such as epoxy or polyethylene. On the other hand, the external coating is applied to the outside surface of the pipe to provide protection against atmospheric corrosion, soil corrosion, and mechanical damage. External coatings are usually made of materials like fusion-bonded epoxy, polyethylene, or polypropylene.

- Q: Can steel pipes be used for electrical conduits?

- No, steel pipes are not typically used for electrical conduits as they are conductive and can pose a safety risk. Electrical conduits are usually made of non-conductive materials such as PVC or metal with insulating coatings.

- Q: What are the different types of pipe connections used with steel pipes?

- There are several types of pipe connections used with steel pipes, including threaded connections, welded connections, flanged connections, and grooved connections.

- Q: How are steel pipes used in the agriculture industry?

- Steel pipes are used in various ways within the agriculture industry. They are commonly used for irrigation systems, allowing water to be efficiently transported to crops. Steel pipes are also used for drainage systems, ensuring excess water is properly removed from fields. Additionally, steel pipes are used for building structures such as barns, fences, and animal enclosures, providing durability and strength.

- Q: How are steel pipes protected against ultraviolet radiation?

- Steel pipes are typically protected against ultraviolet radiation by applying a layer of protective coating or paint. This coating acts as a barrier, preventing the harmful effects of UV rays from deteriorating the steel and reducing its lifespan.

- Q: Are steel pipes recyclable?

- Yes, steel pipes are recyclable.

- Q: Can steel pipes be used in the automotive industry?

- Yes, steel pipes can be used in the automotive industry. They are commonly used for various applications such as exhaust systems, fuel lines, and structural components due to their strength, durability, and resistance to heat and corrosion.

Send your message to us

Black ASTM A106 Gr.B Sch40 seamless steel pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords