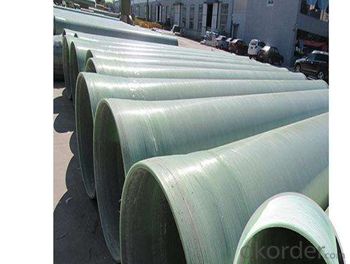

Best Quality Composite Water Pressure FRP Tanks and Vessels with No Toxic of Different Styles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

INSTRUCTION

FRP tanks and vessels can be largely used in many areas of the light industry, petroleum, chemical, food brewing, transportation and so on. Such product can resist the corrosion of various acids, alkalis and salts.

CHARACTERISTICS

• High mechanical strength

• High mechanical inertness

• Resistance to weathering

• Low thermal and electrical conductivity

• Long Life

• Non-toxicity

• No need for maintenance

• Light weight

Resistance to corrosion in aggressive environments is one of

the primary reasons for specifying GRP tanks. These, resists a

wide range of chemicals and temperatures and can be built to

provide additional abrasion, weathering and fire resistance. The

chemical resistance of GRP tank depends primarily on the resin/

glass matrix used. Other factors can affect laminate resistance

including liner construction, cure, and fabrication methodology

and installation techniques.

EXECUTIVE STANDARD

FRP small-scale storage tank

JC/T587-1995 (Glass fiber reinforced plastic storage tank)

Large-scale storage tank

HG/T3983-2007 Industry standards of Chemical Corrosion-resistant jobsite Winding FRP Large-scale storage tank

HG/T20696 Design Requirements of FRP Chemical Equipment

COMPANY INTRODUCTION

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products, professional service and complete solution to our customers. Strong delivery capacity, advanced technology

& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

PICTURE S

FAQ:

Q1:How Can I Get A Sample?

A1:You can get samples by communicate with our export sales.

Q2:How Long Is Delivery?

A2:Delivery time will be30-45days according to order quantity.

Q3:What Is The MOQ?

A3:MOQ depends on different items.

- Q: What should we pay attention to when installing FRP tank for hydrochloric acid?

- The tank shall be placed in a base made of cement bricks. The base height is generally half of the tank. (user if necessary to the company free of charge from the base design) base making site pile method, namely: the hydrochloric acid storage tank placed in the place of use, and then cement bricks to fill up, and pay attention to put some sand filled in the barrel body and the contact surface to be the foundation of cement brick brick, fully solidified, and then cast the use of material.

- Q: What are the features of FRP tanks?

- Tightness is good, never leak, the traditional septic tank is very easy to leak, easy to pollute the ground water, from the floor is generally the smallest, not less than 5 meters. The Chinese style glass septic tank has advanced technology, integrated production, no cracks and no leakage. It can completely avoid the contamination of ground water by the traditional septic tanks and affect the safety of buildings.

- Q: How can the glass steel tank mould be made?

- 2000 cubic, this is a huge number, can only go to the scene winding

- Q: How long is the normal service life of FRP cans? How long will it take if I use it in harsh conditions?

- The quality of the resin will directly affect the service life of your product, and the specific environmental factors need to be analyzed in detail. Suggest you contact specific supplier, put forward your requirement, just can provide the product that you need according to your requirement

- Q: What kind of resin is used to make FRP tanks containing nitric acid?

- Nitric acid is not stable, light or heat will decompose and release of nitrogen dioxide, nitrogen dioxide produced by decomposition of soluble in nitric acid, so that the appearance of a yellowish brown bottle, should be in the shadows to avoid light preservation, can also be saved in the outer frosted plastic bottle (not recommended), is strictly prohibited contact with the agent.

- Q: Physical properties of FRP tanks

- Good thermal performanceFRP has a low thermal conductivity and is 1.25~1.67kJ/ (M. H. K) at room temperature. Only metal 1/100~1/1000 is a good thermal insulating material. It is an ideal thermal protection and ablative material in the instantaneous ultra high temperature, which can protect the spacecraft from the erosion of high velocity air at temperatures above 2000 degrees celsius.

- Q: How much is a 30m about the fand FRP tanks price?

- First of all, what are your fiberglass tanks for? What are the requirements for the material?

- Q: How long is the service life of FRP tanks?

- Rigorous tests abroad have proved that the service life of FRP tanks can be up to 50 years. Since the introduction of Italy technology and equipment in 1986, the first batch of FRP tanks have been used in China so far.

- Q: FRP tank what is impermeable layer?

- By increasing the content of resin and air bubbles and so on control technology, effectively blocking liquid leakage, I FRP tanks Guangzhou Weibo company is to do so

- Q: Glass steel anti-corrosion tank glass steel coating thickness to detect initiation

- A special ultrasonic coating thickness gauge is needed, and the thickness of the coating can not be measured by the ordinary ultrasonic thickness gauge. You may ask below, and they have a solution,

Send your message to us

Best Quality Composite Water Pressure FRP Tanks and Vessels with No Toxic of Different Styles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords