Bagging scale APS series open bag bagging scale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 50 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of APS series open bag bagging scale

APS series automatic bagging scale is a weighing control system that automatically dispenses large quantities of granular, powdery materials into small packages.

Mainly consists of feeding device, weighing unit, bag clamping device, weighing control system, frame components, etc. It can be use din conjunction with sewing machines, conveyors, and other peripheral equipment. It automatically measures the packaging according to different materials and process requirements.

This product has the characteristics of complete architecture, easy operation and reliable performance, and can be adjusted to various production sites and production capacity to meet the needs of users.

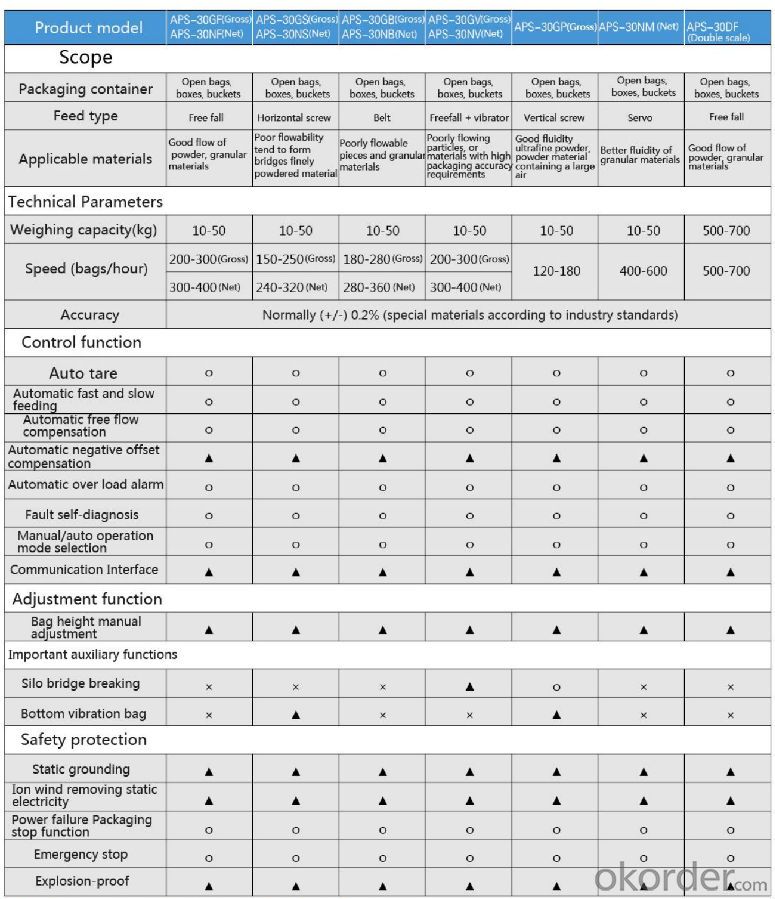

2. APS series

| APS-30GF | Gross weight gravity type |

| APS-30GS | Gross weight screw type |

| APS-30GB | Gross weight belt type |

| APS-30GV | Gross weight vibration type |

| APS-30GP | Vertical screw type |

| APS-30NF | Net weight gravity type |

| APS-30NS | Net weight screw type |

| APS-30NB | Net weight belt type |

| APS-30NV | Net weight vibration type |

| APS-30NM | Net weight servo type |

| APS-30DF | Twin scale gravity type |

3. Technical parameters

P.S:"o"standard function;"▲" optional function; "x" not available.

Main features: suitable for open bags, boxes & buckets with powders, granules, sheet materials

Can be equipped with conveyor, seiwing machine, sealing machine, rewinding machine,press bag shaping machine,.check weigher. metal detector, reject machine, pallet library, stacking machine and other ancillary equipment can realize semi-automatic production or fully automatic production line.

4. Application scope

Suitable for automatic weighing and filling packaging of various open bag packing powdered, granule materials. They are widely used in petrochemical, chemical, plastics, building materials, minerals, fertilizer, grain, feed, food and port industries.

- Q: What are the main functions of packaging machinery?

- The main means of packaging is the use of packaging machinery. With the development of the times and the progress of technology, packaging machinery is playing a more and more important role in the field of packaging

- Q: What are the main plastic forming processes?

- 3. cold pressing molding. Cold pressing molding is also called cold pressing sintering molding. The difference between the cold press molding and the ordinary compression molding is that the material is pressurized and molded at room temperature. The mold after release can be heated or cured by chemical action. This method is used in the forming of polytetrafluoroethylene and some high temperature resistant plastics (such as polyimide, etc.). The general process is three steps of billet sintering cooling.4. transfer molding. Transfer molding is a molding process for thermosetting plastics. When molding, the mold is heated and softened in the heating chamber and then pressed into the mold cavity where it has been heated. According to the different types of transfer molding equipment form: trap type; the tank; the piston.The requirement of plastic molding for transfer molding is that the plastic should have a greater fluidity before reaching the curing temperature, and the curing rate must be faster at the curing temperature. Phenol, melamine, formaldehyde and epoxy resins can meet this requirement.Transfer molding has the following advantages: less waste edge products, can reduce the processing quantity; second molding with fine or brittle insert and perforation of the products, and can keep the insert and the hole position is correct; the product performance is uniform, accurate size, high quality; the mould wear small. The disadvantage is that the manufacturing cost is high compression mold die; the plastic loss; the fiber reinforced plastics for fiber orientation and anisotropy; and around the insert around the plastic, sometimes due to melting is not strong and make the products according to the strength reduction.

- Q: What is the price of a small jujube packing machine?

- Small packaging machine is mainly divided into single grain and multi grain packaging, there are 3-6, there are about 200000. Mainly depends on the performance and use of the machine

- Q: A & B two sets of packaging machines, at the same time packaging quality of 500 kilograms of goods

- 10 bags were randomly extracted from each of them, and the actual quality was measured as follows: (unit G)A: 501500503506504506, 500498497495B: 503504502498499501, 505497502499

- Q: What are the main functions of packaging machinery and equipment?

- Packaging machinery can be realized in the packaging process, including filling and wrapping,

- Q: Food packaging process is not standardized, there is no responsibility?! For example, after the production of candy, because there is no corresponding packaging equipment, the need for artificial packaging

- You can send me a picture of your product and the process, so that I can answer your question exactly. More than 70% of the candies on the market are now automatically packed.

- Q: Which friend is an expert in mechanical equipment or a better understanding of sealing machines? Tell me how to identify the equipment

- Take the food packaging machine for example, if only from the hardware, then you can ask when you buy the degree of automation, semi-automatic or fully automatic, the use of steel ah,

- Q: What are the packaging machines that use temperature control watches?

- A lot of heating machines have to use thermostat

- Q: Donkey hide gelatin cake made of sticky, forming very well, that is, vacuum packaging, after a little sticky in the vacuum bag, what's going on?

- For custom vacuum bags, I would recommend a manufacturer who has customized experience in vacuum bags because it reduces your time cost and offers a lot of advice on packaging design and customization.

- Q: Will the Internet be too passive? Telephone marketing, what kind of food can be found in the factory, such as the phone, people basically do not need, and all have. Does the salesman run the market? How do you run? Thanks for the direction...

- (especially the telephone communication, stop talking no worries) I think you should understand the specific situation, your target customers first, for example: mechanical models currently in use and the time of purchase, production efficiency, what will be improved after the replacement, can recover the cost of even a few years, these are all what you should do in advance homework.

Send your message to us

Bagging scale APS series open bag bagging scale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 50 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords