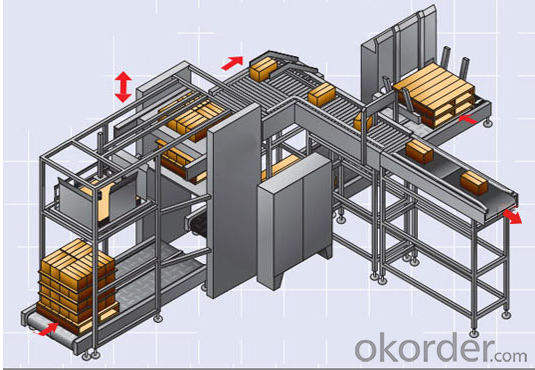

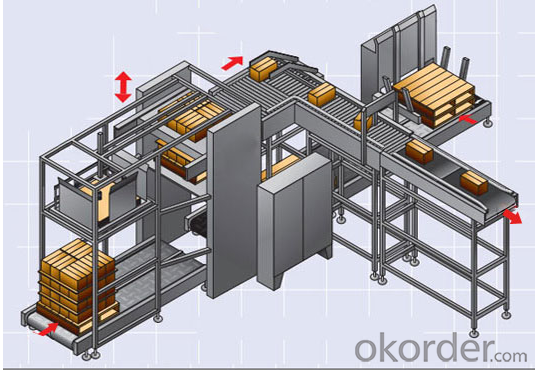

Automatic Depalletizer Machine for Packaging Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Automatic Depalletizer Machine for Packaging Industry

1. Product Description:

The depalletizer is new style one which is researched and developed by absorbing advanced technology aboard. It is suitable for different medium and large beer filling production line, some functions will be changed or added according to the customer's actual requirement. The machine features as easy operation, smooth running, large output and easy maintenance.

2. Product Features:

1) This machine is composed of lift, transfer table, can pushing part, roller 1, roller 2 and operation platform.

2) Elevating part

3) Lift is used for lifting pallets to the height of transfer table and pushing cans to the transfer table by can push parts.

4) Transfer table

5) This part is used for can storage and transport.

6) Can pushing parts

7) It is used for pushing cans to transfer table from pallet.

3. Product Parameters:

Capacity | 800cans/min |

Applicable products | CAN,PE,PP,GLASS BOTTLES |

Totaln Power | 7KW |

Total Weight | 5000kg |

Motor Power | 3x380x3PH |

Copressed air supply | 0.8Mpa |

Applicable stac size(standard) | 1400x1100x2300mm(LXWXH) |

Air Supply Consumption | 0.2m3/min |

Can Conveying Mesh Chain | 4000mm |

Out Dimensions(Standard) | 12700x3500x4300(LXWXH) |

Equipment Capabilities: |

CNC Lathes/Lathes/Automatic Lathes/CNC Shearing Machines/CNC Bending Machines/Machining Center/Grinding Machines/Milling Machines/Turning Machines/ Welding Machines/Cutting machines/ Wire-Cuts/ Laser Cuts/Punching Machines/Ditching machines/Polishing machines/Combined Processing Machines and other specialized processing equipments etc. |

Materials Capabilities: | Aluminum Alloy:5052 /6061/ 6063 / 2017 / 7075 / etc. |

Brass: H59/3602/2604/H62/ etc. | |

Copper/Bronze | |

Stainless Steel:201/202/303/304/316/412/ etc. | |

Steel Alloy: Carbon Steel/Die Steel/etc. | |

Other Special Materials: Lucite / Nylon / Bakelite / Plastic/etc. | |

Various kinds of materials can be chosen, we can produce cnc machined aluminum parts according to your requirement. | |

Surface Treatment: |

Anodizing/ Black Oxide/Electroplating/Heat Treating/Brushing/ Grinding/Polishing/painting /Powder Coating/Nickel plating. |

Inspection tooling: |

Outer micrometer, inside micrometer(machine),digimatic micrometer, internal micrometer, mechanical caliper , vernier caliper ,caliper(digital), caliper(machine),caliper(dial),diameter scale, depth micrometer, digital caliper, altitude gauge, electric balance),2D measurement inspection instruments etc |

4. FAQ:

Q1: What is your delivery time?

A: Generally, the delivery time is 45-60 days after receive the deposit, big production line may take more time.

5. Product Pictures:

- Q: What is the design basis of automated packaging?! Just for today!

- 1. each manipulator is controlled by a single computer. A packaging machine for the completion of complex packaging operations, the need to be completed by a number of robot hand. When the package is completed, the information is monitored and controlled by the computer controlled camera, and the manipulator completes the required actions according to the instructions of the computer program to ensure the quality of the packaging.2. high resolution of material and thickness. In the packaging process, the thickness and material change in packaging materials is not easy for the human eye to identify changes in the design of packaging machinery is often used by the computer control of the camera and the detector to identify the thickness of packing material and material. The camera has now been developed to automatically check and identify pictures of the camera and display it on the screen. At present, the machine in the processing speed can not be changed, the future should be based on the change of the material through discrimination can change the speed, so as to control the work in the optimal state, complete the packaging process in the shortest time, and realize the automatic cleaning, automatic sterilization and automatic cleaning

- Q: Vacuum packing machine for cooked food: can whole chicken, whole goose and whole duck be packed?

- Sometimes, this wine packaging PigHead, with different types of vacuum packaging machine

- Q: The difference between wrapping and bagging is explained from the packaging method, and the difference of the working principle of the packaging machine is analyzed

- A small object, small particle, powder, crystal, liquid, suitable for packing

- Q: Bread packing machine Product features

- Bread packing machine, also commonly known as pillow type packaging machine. Among them, the suitable packing bread model has CM-320 pillow type packing machine, CM-400 pillow type bread packing machine

- Q: What are the main plastic forming processes?

- The main equipment used for molding compression is to press and mold. The most used hydraulic press is self support hydraulic press. The tonnage varies from tens to hundreds of tons. There is a lower press and an upper press. The die used for compression molding is called pressing die. It is divided into three kinds: overflow mould, half overflow mould, no overflow mold.The main advantage of compression molding is that it can be molded into larger flat products and can be produced in large quantities. Its disadvantage is long production cycle and low efficiency.2. lamination forming. A method of combining two or more layers of material of the same or different material by heating and pressurizing with or without a binder.A layer of floating hot pressing plate is arranged between the movable plate and the fixed plate of the press.The reinforcing materials used in laminated forming are cotton cloth, glass cloth, paper and asbestos cloth. The resins are phenolic, epoxy, unsaturated polyester, and some thermoplastic resins.

- Q: What are the packing machines?

- Glass glue category of automatic and manual soft packing machine, chemical, I do not know what you are talking about? You can go and have a look.

- Q: Food packaging process is not standardized, there is no responsibility?! For example, after the production of candy, because there is no corresponding packaging equipment, the need for artificial packaging

- Yes, automatic packing machine. I'm an employee of the automatic packaging machinery company.

- Q: What is the delay time of the packer's cross sealing?

- The sealing time is how long the delay is when the sealing dies are joined together.

- Q: Is there anyone who knows what groups of users of packaging machinery are in general?

- Because the packaging machinery is divided into many types, so many species also have different models, basically need to use packaging products requires packaging machinery, if not to fine some, it is necessary to sort of packaging machinery, slowly down. Packaging machinery is not required to use a certain scale, packaging machinery as well as automatic, semi-automatic, manual distinction. Most small workshops, or small factories, are semi automated or manual. If some of the larger factories will use automatic, or even a whole production line to complete automated packaging.

- Q: Will the Internet be too passive? Telephone marketing, what kind of food can be found in the factory, such as the phone, people basically do not need, and all have. Does the salesman run the market? How do you run? Thanks for the direction...

- (especially the telephone communication, stop talking no worries) I think you should understand the specific situation, your target customers first, for example: mechanical models currently in use and the time of purchase, production efficiency, what will be improved after the replacement, can recover the cost of even a few years, these are all what you should do in advance homework.

Send your message to us

Automatic Depalletizer Machine for Packaging Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords