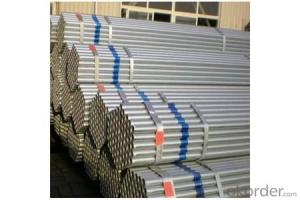

ASTM A53 HOT DIPPED GALVANIZED PIPE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Dip Galvanized seamless steel pipe

Standard: GB,ASTM,DIN,JIS;

Grade: 10#, 20#, 45#, 16Mn;

Length: as customer's demand

Hot Dipped Galvanized Seamless Steel Pipe

1.Standard: ASTM A106,ASTM A53,EN10255,GB/T8162,GB/T8163

2.Material: 10#,20#,ST35,ST37,ST42,ST45

3.Size OD: 18-114.3mm

WT: 2-15mm

Length: 7-12m or according to your requirement.

4.Application: oil and natural gas pipeline, water supply pipeline, boiler, fertilizer factory, chemical

industry, industrial pipeline networks, foundation, construction.

5.Surface: oiled, varnished, black-painted, galvanized, 3PE anti-corrosion, etc

6.Pipe ends:

1). plain end

2). bevelled end

3). both ends threaded, one end with plastic caps protected, the other with socket(couplings) for connecting

4). with hole for casing pipes

5). grooved ends

7.Packing:

1). In bundles, with weaving bags wrapping outside

2). In bare bundles or according to your requirement

- Q: What is the difference between steel pipes and copper-nickel pipes?

- Steel pipes and copper-nickel pipes differ in terms of their composition and properties. While steel pipes are primarily made of steel, copper-nickel pipes are composed of a mixture of copper and nickel. This difference in composition leads to variations in their strength, corrosion resistance, and thermal conductivity. Steel pipes are generally stronger and more durable, making them suitable for high-pressure and heavy-duty applications. On the other hand, copper-nickel pipes have excellent corrosion resistance, particularly in marine environments, and exhibit good thermal conductivity, making them ideal for heat transfer applications. Ultimately, the choice between steel pipes and copper-nickel pipes depends on the specific requirements and conditions of the intended use.

- Q: Does seamless steel tube have a bend of 135 degrees?

- In engineering, it is usually marked as "45 elbow" and has no "135" mark. The angle of the elbow is acute, so there will be no more than 90 degrees elbow.Elbow is a common connecting pipe used in plumbing and heating. It is used for the connection of the bend of pipe, and is used to change the direction of pipe.

- Q: How are steel pipes graded?

- Steel pipes are graded based on various factors such as the composition of steel, manufacturing process, and physical properties like strength, durability, and corrosion resistance. These grades are assigned based on internationally recognized standards such as ASTM, API, and ISO, which provide specific criteria for different applications and industries.

- Q: Can steel pipes be used for conveying compressed air?

- Yes, steel pipes can be used for conveying compressed air. Steel pipes are known for their high strength and durability, making them suitable for handling high-pressure applications such as compressed air systems. Additionally, steel pipes are resistant to corrosion and can withstand extreme temperatures, making them a reliable choice for conveying compressed air.

- Q: What are the different types of steel pipe coatings for marine applications?

- There are several types of steel pipe coatings commonly used for marine applications, including epoxy coatings, polyurethane coatings, and fusion bonded epoxy (FBE) coatings. These coatings are designed to protect the steel pipe from corrosion and provide resistance to marine environments. Epoxy coatings are known for their excellent adhesion and chemical resistance, while polyurethane coatings offer enhanced abrasion resistance. FBE coatings are highly durable and provide excellent corrosion protection. The choice of coating depends on the specific requirements of the marine application and the level of protection needed.

- Q: How are steel pipes used in the manufacturing of automotive exhaust systems?

- Steel pipes are commonly used in the manufacturing of automotive exhaust systems as they possess high strength, durability, and resistance to heat and corrosion. These pipes are used to transport exhaust gases from the engine to the tailpipe, ensuring the safe and efficient operation of the vehicle. They are typically bent and welded together to create a complex network of pipes that helps direct the flow of exhaust gases and reduce noise levels. Overall, steel pipes play a crucial role in the construction of automotive exhaust systems, contributing to their reliability and longevity.

- Q: Can steel pipes be used for both high-pressure and low-pressure systems?

- Yes, steel pipes can be used for both high-pressure and low-pressure systems. Steel pipes are known for their durability and strength, making them suitable for various applications, including both high and low-pressure systems. However, it's important to consider the specific requirements and regulations of the system to ensure the appropriate type and grade of steel pipe is selected for optimal performance and safety.

- Q: How do steel pipes compare to other materials like PVC or copper?

- There are several advantages to using steel pipes compared to materials like PVC or copper. Firstly, steel pipes are known for their strength and durability. They can withstand high pressure and extreme temperatures without cracking or bending, making them ideal for heavy-duty applications such as industrial piping systems or underground installations. Secondly, steel pipes have excellent corrosion resistance. Unlike copper pipes that can corrode over time, steel pipes are typically coated with anti-corrosive materials like zinc or epoxy. This protective layer prevents rust and ensures a longer lifespan for the pipes. Furthermore, steel pipes offer superior fire resistance compared to PVC or copper. They are non-combustible and can withstand high temperatures for extended periods without deforming or releasing toxic gases. This makes steel pipes a safer option for applications where fire hazards are a concern. In terms of cost, while steel pipes may initially be more expensive than PVC, they offer better long-term value due to their durability and longevity. On the other hand, copper pipes can be quite expensive and are susceptible to theft due to their scrap value. Lastly, steel pipes are highly versatile and can be used in various applications such as water supply, sewage systems, gas pipelines, and oil refineries. They can handle high volumes of fluid with ease and are resistant to external factors like UV rays or physical impacts. Overall, steel pipes are a reliable and efficient choice for many industries and applications, offering strength, durability, corrosion resistance, fire resistance, and versatility that sets them apart from materials like PVC or copper.

- Q: What is ND steel pipe?

- ND steel 09CrCuSb steel is currently the most ideal "resistance to sulfuric acid dew point corrosion in steel (ND steel, ND steel, 09CrCuSb steel, 09CrCuSb steel), ND steel is widely used in the manufacture of economizer, served in the high sulfur content in flue gas of air preheater, evaporator and heat exchanger equipment for resist sulfur smoke gas dew point corrosion.

- Q: What are the factors to consider when selecting pipe materials for corrosive environments?

- To ensure the longevity and effectiveness of a piping system in corrosive environments, several important factors must be considered. Firstly, the corrosion resistance of the pipe material is crucial. It is essential to select a material highly resistant to corrosion as time can cause significant damage to pipes in corrosive environments. Stainless steel, fiberglass, PVC, and CPVC are materials known for their excellent corrosion resistance. Secondly, the chemical compatibility of the pipe material with the corrosive environment should be assessed. Different materials have varying resistance levels to different chemicals, so it is important to ensure that the chosen material can withstand the specific chemicals present. Consulting chemical compatibility charts and seeking expert advice can aid in selecting the right material. Furthermore, the temperature and pressure requirements within the corrosive environment should be taken into account. Some materials have limitations in terms of temperature and pressure resistance, exceeding which can lead to pipe failure. It is crucial to choose a material that can handle the required temperature and pressure ranges without compromising its structural integrity. The cost of the pipe material and its installation should also be considered. While certain materials may offer high corrosion resistance, they may also be more expensive. Striking a balance between the desired level of corrosion resistance and the available budget is essential. Lastly, the maintenance requirements and overall durability of the pipe material should be evaluated. Some materials may require more frequent inspections, cleaning, or repairs compared to others. Considering the anticipated lifespan of the piping system and the ease of maintenance can help in selecting a material that ensures long-term reliability and cost-effectiveness. In conclusion, when selecting pipe materials for corrosive environments, it is important to consider factors such as corrosion resistance, chemical compatibility, temperature and pressure requirements, cost, and maintenance and durability. By carefully evaluating these factors, one can choose a pipe material that best suits the specific corrosive environment and ensures a reliable and long-lasting piping system.

Send your message to us

ASTM A53 HOT DIPPED GALVANIZED PIPE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords