Astm 316 321 Stainless Steel Sheets in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

ASTM

Technique:

Hot Rolled

Shape:

Square

Surface Treatment:

Polished

Steel Grade:

300 Series

Certification:

SGS

Thickness:

4

Width:

1500

Length:

6000

Net Weight:

32

Astm 316 321 Stainless Steel Sheets in China

Features:

1.Accurate dimension

2.Minimum mainenance

3.Excellent service life

4.Non Corrosive

5.Heat Resistant

| ITEM | DESCRIPTION |

| Product | Stainless Steel Sheet |

| Standard | JIS, AISI, ASTM, GB, DIN, EN, etc. |

| Material | 201, 202, 304, 304L, 316, 310S, 316L, etc. |

| Thickness | 0.1mm-150mm |

| Width | 500mm-3000mm |

| Length | 500mm-6000mm |

| Certificate | BV, ISO, SGS, etc. |

| Application | Widely |

| MOQ | 1 Ton |

| Brand | TISCO, LISCO, POSCO. |

| Type | Plate |

| Port | Shanghai,China |

| Payment | L/C,T/T |

| Place of origin | Jiangsu, China |

| Product Ability | 3000 tons per month. |

| Package | Standard seaworthy export packing or according to the customers' request. |

| Delivery Time | It is based on the order, normally within 10 days after receiving your advance payment. |

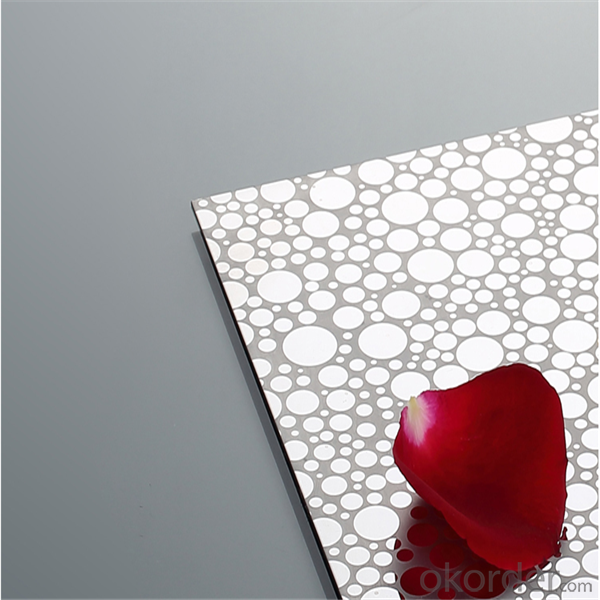

| Surface and application | ||

| SURFACE | DEFINITION | APPLICATION |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

| HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

| BA (No.6) | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building Construction. |

| Mirror (No.8) | Shinning like a mirror. | Building construction. |

| The Chemical Composition | |||||||||||

| C | Cr | Ni | Mn | P | S | Mo | Si | Cu | N | ||

| 201 | 1Cr17Mn6Ni5N | ≤0.15 | 16.00-18.00 | 3.50-5.50 | 5.50-7.50 | ≤0.060 | ≤0.030 | - | ≤1.00 | - | ≤0.25 |

| 202 | 1Cr18Mn8Ni5N | ≤0.15 | 17.00-19.00 | 4.00-6.00 | 7.50-10.00 | ≤0.060 | ≤0.030 | - | ≤1.00 | - | ≤0.25 |

| 301 | 1Cr17Ni7 | ≤0.15 | 16.00-18.00 | 6.00-8.00 | ≤2.00 | ≤0.065 | ≤0.030 | - | ≤1.00 | - | - |

| 304 | 1Cr18Ni9 | ≤0.07 | 17.00-19.00 | 8.00-10.00 | ≤2.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | - | - |

| 304L | 00Cr19Ni10 | ≤0.030 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | - | - |

| 309S | 0Cr23Ni13 | ≤0.08 | 22.00-24.00 | 12.00-15.00 | ≤2.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | - | - |

| 310S | 0Cr25Ni20 | ≤0.08 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | - | - |

| 316 | 0Cr17Ni12Mo2 | ≤0.08 | 16.00-18.50 | 10.00-14.00 | ≤2.00 | ≤0.035 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | - |

| 1Cr18Ni12Mo2Ti6) | ≤0.12 | 16.00-19.00 | 11.00-14.00 | ≤2.00 | ≤0.035 | ≤0.030 | 1.80-2.50 | ≤1.00 | - | - | |

| 0Cr18Ni12Mo2Ti | ≤0.08 | 16.00-19.00 | 11.00-14.00 | ≤2.00 | ≤0.035 | ≤0.030 | 1.80-2.50 | ≤1.00 | - | - | |

| 316L | 00Cr17Ni14Mo2 | ≤0.030 | 16.00-18.00 | 12.00-15.00 | ≤2.00 | ≤0.035 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | - |

| 317 | 0Cr19Ni13Mo3 | ≤0.12 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0.035 | ≤0.030 | 3.00-4.00 | ≤1.00 | - | - |

| 317L | 00Cr19Ni13Mo3 | ≤0.08 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0.035 | ≤0.030 | 3.00-4.00 | ≤1.00 | - | - |

| 321 | 1Cr18Ni9Ti6) | ≤0.12 | 17.00-19.00 | 8.00-11.00 | ≤2.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | - | - |

| 430 | 1Cr17 | ≤0.12 | 16.00-18.00 | ≤1.25 | ≤0.035 | ≤0.030 | - | ≤1.00 | - | - | |

| 430F | Y1Cr17 | ≤0.12 | 16.00-18.00 | ≤1.00 | ≤0.035 | ≥0.15 | - | ≤0.75 | - | ||

- Q: What is the hardness of stainless steel sheets?

- The hardness of stainless steel sheets can vary based on the specific grade and manufacturing process employed. Typically, stainless steel sheets are renowned for their exceptional hardness and strength. In industrial applications, the most commonly utilized grades, such as 304 and 316, exhibit a hardness range of 70-90 HRB (Rockwell hardness B scale) or 150-200 HV (Vickers hardness). However, there are also specialized stainless steel alloys available that can possess even higher degrees of hardness, such as precipitation-hardened grades like 17-4 PH, which can attain hardness levels of 30-40 HRC (Rockwell hardness C scale). To determine the precise hardness of a particular stainless steel sheet, reference to the manufacturer's specifications or performing hardness testing utilizing appropriate methods and equipment is necessary.

- Q: What are the different surface finishes available for stainless steel sheets?

- Stainless steel sheets come in a variety of surface finishes, each with its own unique characteristics and aesthetics. Let's explore some of the options available: 1. The No.1 Finish is the most commonly used finish for stainless steel sheets. It has a rough and dull appearance with visible grain lines. This finish is achieved through hot rolling and is suitable for applications where a rough finish is acceptable. 2. For a smooth and slightly dull surface, the No.2B Finish is ideal. It is obtained by cold rolling and annealing the stainless steel. This finish is commonly used for kitchen appliances, architectural accents, and decorative purposes. 3. Similar to the No.2B Finish, the No.2D Finish also involves cold rolling and annealing. However, it has a smoother and shinier appearance, making it suitable for applications that require a more polished look. 4. The No.3 Finish, also known as a brushed finish, is achieved by polishing the stainless steel with abrasive belts or brushes. It creates a unidirectional satin-like appearance, often used for decorative purposes in architecture and interior design. 5. If you desire a more refined and smoother appearance, the No.4 Finish is the way to go. This finish is obtained by polishing the stainless steel with finer abrasive belts or brushes than the No.3 Finish. It is commonly used for decorative purposes, such as elevator panels, kitchen equipment, and automotive trim. 6. For a highly reflective surface, the No.8 Finish, also known as a mirror finish, is perfect. This finish is achieved by continuously polishing the stainless steel with finer abrasive materials until a glossy, mirror-like appearance is obtained. It is ideal for architectural and decorative applications. 7. The Hairline Finish is achieved by mechanically polishing the stainless steel surface with a fine abrasive material. It creates a subtle, linear pattern with a matte appearance, commonly used for architectural accents, appliances, and decorative items. These are just some of the most common surface finishes available for stainless steel sheets. The choice of finish will depend on the desired aesthetics, functionality, and application requirements.

- Q: What are the fire resistance properties of stainless steel sheets?

- Stainless steel sheets have excellent fire resistance properties due to their unique composition and structure. Unlike other materials, stainless steel does not readily burn or ignite when exposed to high temperatures. This is primarily because stainless steel contains a high percentage of chromium, which forms a thin, protective oxide layer on the surface of the material when exposed to air. This oxide layer acts as a barrier, preventing the underlying steel from reacting with oxygen and further resisting fire. Furthermore, stainless steel has a high melting point, typically around 1400-1450°C (2552-2642°F), which is significantly higher than most common building materials. This means that stainless steel sheets can withstand extreme heat without deforming or losing their structural integrity, providing additional fire protection. Additionally, stainless steel is non-combustible, meaning it does not contribute to the fuel load of a fire. This characteristic is particularly important in construction and industrial applications, where fire safety is a top priority. Overall, the fire resistance properties of stainless steel sheets make them an ideal choice for various applications, including building construction, transportation, and industrial settings, where fire protection is necessary.

- Q: Are stainless steel sheets suitable for heat transfer equipment?

- Yes, stainless steel sheets are suitable for heat transfer equipment. Stainless steel has excellent thermal conductivity properties, which means it can efficiently transfer heat from one medium to another. It can withstand high temperatures without warping or deforming, making it ideal for use in heat transfer applications. Additionally, stainless steel is corrosion-resistant, ensuring the longevity and durability of the equipment. Its hygienic properties also make it suitable for industries where cleanliness is crucial, such as food and pharmaceutical industries. Overall, stainless steel sheets are a reliable and efficient choice for heat transfer equipment.

- Q: How do I prevent fingerprints or smudges on stainless steel sheets?

- To prevent fingerprints or smudges on stainless steel sheets, you can try using a microfiber cloth or a soft cotton cloth to wipe the surface regularly. Avoid using abrasive cleaners or scrub brushes that can cause scratches. Additionally, you can use a stainless steel cleaner or a mixture of water and mild dish soap for deeper cleaning.

- Q: How do you polish stainless steel sheets?

- To polish stainless steel sheets, you can start by cleaning the surface thoroughly to remove any dirt or grime. Then, use a stainless steel cleaner or a mixture of mild detergent and warm water to wipe the sheets in the direction of the grain. Next, rinse the sheets with clean water and dry them with a soft cloth. Finally, apply a stainless steel polish or a mixture of vinegar and olive oil to a clean cloth, and gently buff the sheets in circular motions to restore their shine and remove any remaining stains or smudges.

- Q: What is the thickness range for stainless steel sheets?

- The thickness range for stainless steel sheets can vary depending on the specific grade and application. Generally, stainless steel sheets are available in thicknesses ranging from 0.4mm to 6mm. However, for specialized applications, thinner or thicker sheets may be required. It is important to consult with a supplier or refer to industry standards to determine the appropriate thickness range for a specific project or application.

- Q: How do you put the mirror panel on the stainless steel panel?

- Stainless steel passivation treatment (passivation, of, stainless, steel)Our company specializes in stainless steel surface treatment, providing all types of stainless steel pickling and passivation processing business.The company adopts advanced passivation process and self matching passivation reagent, according to your passivation requirements for the preparation of products, targeted, fully guarantee your passivation process all the requirements.We can not only become your processing partner, but also willing to become a partner with you.

- Q: Inspection method for stainless steel welding

- 1) measurement, in strict accordance with the requirements of the drawings, and to ensure that within tolerance. Along the column, a top cover, and frame, beam should be straight, without distortion, the straightness (nonstraightness) should meet the requirements on the table diagonal method.2) no distortion, swing, rotation or displacement are allowed in the structures which are completely fixed

- Q: Stainless steel plate surface treatment: ink, wire drawing, polishing what role?

- Oil mill, also known as "snow silk", "broken wire", is a kind of anti fingerprint drawing, used in the elevator car. It is to use the 4# wire drawing machine grinding, with grease to reduce the temperature generated by the board, so that the board surface to maintain smooth, non deformation

Send your message to us

Astm 316 321 Stainless Steel Sheets in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords