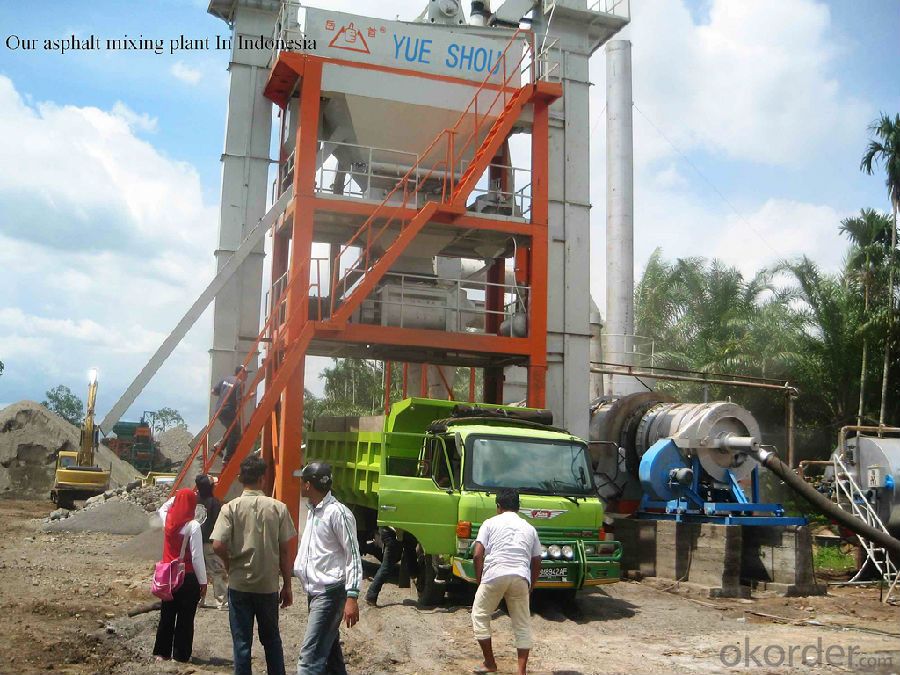

asphalt mixing plant LB800 capacity 64t/h,good reputation in russian,Top 10 in 2014,hot sale LB1500 in russian

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

LB800 Asphalt Mixing Plant with capacity 64t/h

Item | Description | Qty. (set) |

01 | Cold Aggregate Batching Machine and Feeders Group of four components, unit capacity of the aggregate hopper is 5M³ (full hopper), total capacity is 20M³; Adopts imported variable-frequency governor Continuous dosing belt & and driving reduction motor group, group of 4 units; The electric vibrato: 2 units | 1 |

02 | Feeding belt conveyor | 1 |

03 | The Drying Drum Ø1450×6300 MM, rotating speed: 11.3 RPM; Cylinder on frame, Rotation drive through electric motor and reduction box, The heat-preservation is 50mm rack wool and stainless steel | 1 |

04 | EBICO Gas burners Fuel :Natural gas | 1 |

05 | Cyclone dust collector |

|

06 | Bag dust collector |

|

07 | The hot aggregate elevator: capacity 80 T/H | 1 |

08 | The filler bin: 0.6 M³, the capacity of the filler elevator: 25T/H | 1 |

08 | The vibrating screen unit 4 grades, capacity 80T/H | 1 |

09 | The hot aggregate storage bin 4 numbers, the total volume is 10 M³, 4 units level indicator, temperature detector | 1 |

10 | The weighing devices The weighing unit for powder, aggregate and bitumen (each has one unit) | 1 |

11 | The mixing tower The main tower with supporting legs, repairing platform and guardrail | 1 |

12 | The mixer Capacity: 800 KG/batch, the motor power: 30KW | 1 |

13 | Vibration screen |

|

14 | Asphalt supply system and heating system 2 units 25 tons bitumen tank with hot oil heating system |

|

15 | Pneumatic control system | 1 |

16 | Electric control system |

|

17 | Control room |

|

18 | With 30ton bottom-set finished mixture storage tank | 1 |

- Q: What raw materials and equipment do you need for your own admixture?

- Admixtures seem simple, but they are actually a practical science. You want to get the ideal admixtures from the books or the web, "that's quite", and you're in the concrete mixing station. The concrete cost control of the mixing station is relatively strict, and the performance of the admixture is different

- Q: The main components of a mixing station

- Feeding system: aggregate bucket, aggregate weighing hopper, flat belt machine, inclined belt conveyor. Mixing system: the main machine is a double-deckshaft mixer, reducer, cement weighing hopper, water and additive weighing hopper. Cement supply system: cement warehouse, screw conveyor, air compressor, screw electronic. Automatic water supply system: water tank, pump, pipe. Electrical operating system: computer console, electric control cabinet, operation room. Operation control system: microcomputer control or manual control.

- Q: What is the concrete of the mixing station?

- Concrete mixing stations are made of concrete, which is made of concrete for various construction sites, including commercial housing, concrete floor, industrial workshop and so on.

- Q: What type of concrete mixer is needed for each hour of concrete 90 cubic meters?

- If it's a theoretical one, it's going to build 90 lines per hour, which is 90 square hours per hour, and if it's actually 90 square, it's going to be at least 120 stations.

- Q: How much water does a concrete mixer use every day?

- It is also a waste of water to flush the transports. Suppose you flush a vehicle with 1-2t water, rinse it 2-3 times a day, and use 20 cars a day for a medium size of a blender, 40 to 120 t a day. From this perspective, the reuse of washing water is very conducive to environmental protection and water conservation. The rational recycling of water in the mixing stations is also gradually being promoted. Our new hydraulic patent product concrete wastewater and sewage circulation recycling used by many domestic manufacturers, most of new mixing plant began to use the recycling equipment. The wastewater recovery system has made some efforts for the environmental cause of China.

- Q: How to choose a good concrete mixer station?

- For simple concrete mixup stations, the overall cost of equipment is much cheaper, because the configuration is different and a lot of configuration is eliminated. But cement weighing cannot save configuration independent water weighing measurement more accurate to efficient, do not use water weighing system can also be mixing concrete, but there is a big hidden trouble. The water weighing system is not suitable for individual water weighing system, and it can reduce the investment of a simple mixing station by about 7, 000 yuan. And shortcomings is not water in the mixing drum of the weighing system and water, time node device can be used to set the water within a certain time interval to churn, but increased water and forced concrete mixer mixing time, still can cause concrete model is not stable. Therefore, although do not use water weighing system can save investment, but will increase the mixing time of concrete and affect the stability of the concrete, so the customer can choose according to oneself circumstance.

- Q: What constitutes the js750 concrete mixing station

- The concrete mixing station consists of the mixing system, the aggregate supply system, the measuring system, the control system and the external supporting equipment. The main purpose of the mixing station is to mix concrete, also called concrete mixing station. HZS series products adopt international popular cement concrete mixing station quickly assembled module type structure, high-performance imported agitator, double machine double control way of computer control, prevent noise, prevent dust pollution, environmental design, is the new generation of cement concrete mixing equipment, applicable to urban commodity ready-mixed concrete, road and bridge, water conservancy, airports, ports and other large infrastructure construction project and concrete demand for large sites.

- Q: What are the advantages of HZS series of concrete mixing stations

- Is economical and practical type of small and medium sized concrete mixing station mixing plant, usually more than township, built in the smaller areas, compared with large mixing station the installed it easier, and covers an area of small, transportation is convenient.

- Q: What chemical materials are used in the concrete mixing station?

- It is the raw materials for the concrete mixers, the sand, stone, cement, fly ash, mineral powder, various admixtures, water, basically these seven raw materials

- Q: The average commodity concrete is mixed with a day to use how much fly ash

- What is the amount of cement in the concrete mixing station? This is based on the different levels of the concrete mix. Here is a different grade of concrete ingredients: Note: 1. The mix of concrete and concrete shall be carried out in uniform ratio of gravel and slump. In one project, the C40 is mixed with ordinary cement, and according to the proportion design, the maximum amount of coal ash can replace 40% of the cement consumption.

Send your message to us

asphalt mixing plant LB800 capacity 64t/h,good reputation in russian,Top 10 in 2014,hot sale LB1500 in russian

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords