Apple Plywood Melamine Faced Chipboard Particle Board 1220x2440x16mm

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

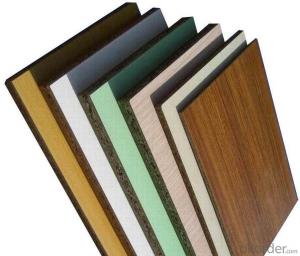

1220x2440x16mm melamine particle board/chipboard

Size:4x8,5x8,6x8,6x9

Thickness:3~30mm

Color:any color

Certificate:ISO9001

Description

Size: 4x8 6x8 6x9 or as your requirement

Thickness: 2.0-30mm

Density: 690-750kg/m

Substrate board: MDF, PARTICLE BOARD, PLYWOOD, BLOCKBOARD, etc

Surface finish: matt, ray, flat, embossed, glossy finish in melamine

Glue: E2, E1, E0

Features:

1. Smooth surface , high gloss, scratch resistant and UV stabilized resistant.

2. Fireproof, environmentally-friendly, moisture-proof.

3. Corrosion resistance, economical, stylish and durable etc.

4. High bending strength and easy to work.

5. Surface comparable to gloss /mirror finish.

FAQ:

1.Sampling:

We kindly understand an order intention is outlined with a sample order request. Therefore, we welcome customers to initiate a business opportunity by giving us a sample order as a trial of our quality and service. We are confident you will be positively impressed with our professionalism, quality and service.

2.Sample Lead Time:

Sample Lead Time: 3-7 working days

Production Lead Time: 15-20 days after received the deposit

3.Sample Fee:

Free sample available with freight collect

4.Customizations of MDF

1. Thickness

2. Finish

3. Material

4. Surface

5. Size

6. Density

7. Glue

8. Logo

9. Packing

- Q: Plywood in the material defects?

- discoloration discoloration Where the normal color of wood changes called color, can be divided into two kinds of chemical discoloration and fungal discoloration.

- Q: National standards for decorative veneer veneer plywood performance requirements

- China is the recommended standard GB / T 15104-94 "decorative veneer veneer board", the vast majority of enterprises to implement the implementation of this standard

- Q: Selection of plywood in plywood production

- Artificial veneer is the use of relatively low prices of logs cut into veneer, made by a certain process pressure made of wood, and then cut into a beautiful pattern decorated veneer.

- Q: According to the different composition of the glue, for the construction of plywood with the following types of glue

- High-quality urea-formaldehyde glue / melamine glue / phenolic glue can reach E0 level, E1 level, that can be used directly for indoor

- Q: The Decorative veneer veneer plywood grade classification

- for example,such as some manufacturers logo level "AAA", which is corporate behavior.

- Q: What are the key points for plywood selection?

- if you do not consider the panel pattern and color, should also be based on the environment and reasonable cost Selection of plywood grade, category

- Q: Now the market prospects for plywood

- regulate export order. With the expansion of China's infrastructure construction and the strengthening of the development of the Midwest, plywood market has great potential.

- Q: Material for the plywood defects which

- Decay rot due to the invasion of wood rot fungi, the cell wall material decomposition, resulting in loose wood, strength and density decreased, wood tissue and color are often changing.

- Q: What are the shortcomings of plywood

- A group of veneers are usually in the direction of adjacent layers of wood grain perpendicular to the formation of each other, usually its table and the inner plate symmetrically arranged in the center layer or plate on both sides

- Q: The basic principle of plywood

- First, symmetry; Second, adjacent layers of single-board fiber perpendicular to each other

Send your message to us

Apple Plywood Melamine Faced Chipboard Particle Board 1220x2440x16mm

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords