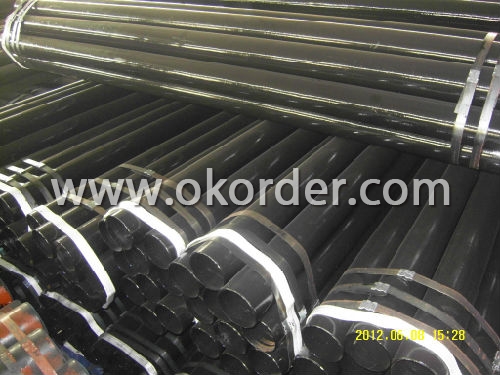

API 5L X56 Line Pipe

- Loading Port:

- SHANG HAI Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5OMT m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

- Q: Can steel pipes be used for wastewater disposal?

- Yes, steel pipes can be used for wastewater disposal. Steel is a durable and corrosion-resistant material, making it suitable for transporting and disposing of wastewater safely and efficiently.

- Q: How are steel pipes used in the construction of offshore platforms?

- Steel pipes are used in the construction of offshore platforms primarily for their strength and durability. These pipes serve various purposes such as transporting fluids, providing structural support, and enabling the installation of essential equipment. They are commonly used for the fabrication of underwater pipelines, risers, and conductor casings, ensuring efficient and reliable operations in harsh marine environments.

- Q: Are steel pipes suitable for structural purposes?

- Yes, steel pipes are suitable for structural purposes. Steel pipes are known for their strength, durability, and versatility, making them an excellent choice for various structural applications. They can withstand heavy loads, provide excellent structural support, and are resistant to corrosion and extreme weather conditions. Steel pipes are commonly used in construction projects, bridges, buildings, and infrastructure systems such as water and gas pipelines. Additionally, steel pipes can be easily welded, bent, and cut to meet specific structural requirements, making them highly adaptable for different construction needs. Overall, steel pipes are widely recognized as a reliable and efficient choice for structural applications.

- Q: How are steel pipes used in the construction of underground parking structures?

- Steel pipes are used in the construction of underground parking structures for various purposes, such as providing structural support, drainage, and ventilation. They are commonly used as piles or caissons to support the weight of the structure and prevent it from sinking into the ground. Additionally, steel pipes are utilized for the installation of drainage systems to prevent water accumulation and ensure the structural integrity of the parking structure. They are also employed for ventilation purposes, allowing fresh air to circulate and remove any potentially hazardous gases. Overall, steel pipes are essential components in the construction of underground parking structures, ensuring their stability, safety, and functionality.

- Q: Can steel pipes be used for steam applications?

- Yes, steel pipes can be used for steam applications. Steel pipes have high strength and durability, making them suitable for carrying high-pressure steam. They can withstand the high temperatures and pressures associated with steam, making them a reliable choice for steam transportation in various industries.

- Q: What are the different types of thread connections used in steel pipes?

- There are several types of thread connections commonly used in steel pipes, including tapered threads such as NPT (National Pipe Taper), which are designed to create a tight seal, and straight threads like NPS (National Pipe Straight), which are often used for mechanical applications. Additionally, some other types of thread connections used in steel pipes include BSP (British Standard Pipe), which is widely used in Europe, and API (American Petroleum Institute) threads, which are commonly used in the oil and gas industry.

- Q: Can steel pipes be used for transporting liquids and gases?

- Yes, steel pipes can be used for transporting liquids and gases. Steel pipes are commonly used in various industries, such as oil and gas, water supply, and chemical processing, due to their durability, strength, and resistance to corrosion. They are capable of safely and efficiently transporting a wide range of liquids and gases over long distances.

- Q: What are the different methods of pipe welding for steel pipes?

- There are several methods of pipe welding for steel pipes, including Shielded Metal Arc Welding (SMAW), Gas Metal Arc Welding (GMAW), Flux-Cored Arc Welding (FCAW), Submerged Arc Welding (SAW), and Tungsten Inert Gas Welding (TIG). Each method has its own advantages and is used depending on the specific requirements of the project, such as the thickness of the pipe, the type of steel, and the desired weld quality.

- Q: Can steel pipes be used for underground sewage treatment plants?

- Yes, steel pipes can indeed be used for underground sewage treatment plants. Steel pipes are commonly used in underground applications due to their durability, strength, and resistance to corrosion. They are capable of withstanding the harsh underground environment and can efficiently transport sewage from one area to another within the treatment plant. Moreover, steel pipes can be customized to meet the specific requirements of the sewage treatment plant, such as different diameters and wall thicknesses, ensuring proper flow and drainage. Additionally, steel pipes can be coated or lined with protective materials to enhance corrosion resistance, further extending their lifespan. Overall, steel pipes are a reliable and suitable choice for underground sewage treatment plants.

- Q: What are the safety measures to consider when working with steel pipes?

- When working with steel pipes, it is important to consider several safety measures. Firstly, wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots is crucial to protect against potential injuries. Secondly, ensuring proper ventilation in the work area is important to avoid inhalation of harmful gases or fumes. Additionally, practicing proper lifting techniques and using mechanical aids when handling heavy pipes can prevent strains or back injuries. It is also essential to be cautious of sharp edges or protruding objects on the pipes and to secure them properly to prevent accidents. Lastly, following established safety protocols, such as conducting regular inspections and adhering to lockout/tagout procedures, helps minimize the risk of accidents or equipment malfunctions.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 1990 |

| Annual Output Value | Above 30 milionrmb |

| Main Markets | Germany; Japan;Korea; America; Brasil; Canada |

| Company Certifications | ISO9001:2000 ; API |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 50% |

| No.of Employees in Trade Department | Above 10 |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 8,5000square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High Average |

Send your message to us

API 5L X56 Line Pipe

- Loading Port:

- SHANG HAI Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5OMT m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords