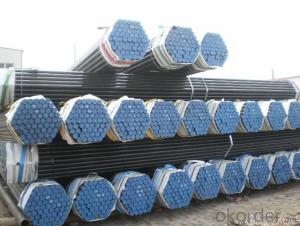

API 5CT Oil Tubing and Tubing Pipe Seamless and Erw

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1t m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application of API 5CT Oil Tubing and Tubing Pipe Seamless and Erw:

used for the fluid transport and gas and oil

for the industrial usage and oil .

Package and Delivery of API 5CT Oil Tubing and Tubing Pipe Seamless and Erw:

Package Detail: As clientes' requirements.

Delivery: 40~60 days

Specification of API 5CT Oil Tubing and Tubing Pipe Seamless and Erw:

(1) according to SY / T6194-96provisions of domestic casing, casing of indeterminate length scale, the scope of the 8-13m. But not short in6m casing can provide, their number must not exceed 20%.

(2) the casing inside and outside surface should be folded, hairline, separation, crack, crease and scarring. These defects should be completely removed, clear the depth should not exceed12.5% of the nominal wall thickness.

(3) coupling, the surface shall be folded, hairline, separation, crack, crease, scab defect.

(4) casing and coupling thread surface should be smooth, no burr is allowed, tear and to make thread interrupt effect of strength and tightly connected with other defects.

Product information of API 5CT Oil Tubing and Tubing Pipe Seamless and Erw:

Specification | Dimension | Wallthickness | Length | Sorts |

Oil Casing Pipe (with Coupling or not ) | 1.315”-20” | 3.38mm-35mm | About 9.5m | Bare Pipe , NU Casing Pipe, EU Casing Pipe |

Pipe line Pipe | 10mm-1420mm | 1.5mm-150mm | About 11.5m | Bare pipe , and Casing Pipe |

Standards: API5L ,API 5CT. | ||||

Oil Casing Pipe Material:N80 ,J55,L80, P110 | ||||

Pipe Line Pipe Material :L360 ,L245,L390,X42,X60,X65,X70

| ||||

Usage Scope: used for transport the oil and gas underground or on the groud . | ||||

Surface Treatment:1/2/3 layer PE coated , Painting , Coated Exloy resin or according to your requirement . | ||||

- Q: How are steel pipes used in the manufacturing of automobiles?

- Due to their strength, durability, and versatility, steel pipes find widespread use in the manufacturing of automobiles. Throughout the automobile manufacturing process, various applications make use of steel pipes. One primary application of steel pipes in automobiles lies in constructing the vehicle's chassis and body. Structural components, such as steel pipes, provide the necessary strength and rigidity. With the ability to be bent, shaped, and welded, steel pipes prove to be an ideal choice for automotive purposes. Additionally, steel pipes play a crucial role in the exhaust system of automobiles. Responsible for guiding and redirecting exhaust gases away from the engine, steel pipes form the exhaust manifold. They also contribute to the exhaust pipes and mufflers. Steel's high temperature and corrosion resistance make it suitable for enduring the harsh conditions of the exhaust system. Moreover, steel pipes serve in the cooling system of automobiles. They facilitate the transportation of coolant from the engine to the radiator and back, effectively regulating the engine's temperature. Due to their ability to handle high pressure and temperature, as well as their resistance to corrosion and chemical damage, steel pipes remain the preferred choice for this application. Furthermore, steel pipes find usage in the fuel system of automobiles. They ensure a consistent and reliable supply of fuel by transporting it from the tank to the engine. Steel pipes are selected for this purpose because of their resistance to corrosion and their ability to withstand the high pressure and temperature associated with fuel transportation. In conclusion, steel pipes are indispensable in automobile manufacturing. They contribute significantly to the construction of the chassis and body, the exhaust system, the cooling system, and the fuel system. Thanks to their strength, durability, and versatility, steel pipes are the preferred choice for various automotive applications.

- Q: Can steel pipes be used for hydropower systems?

- Hydropower systems can indeed utilize steel pipes. For a variety of purposes in these systems, steel pipes are commonly employed, particularly for penstocks, which facilitate the transportation of water from a reservoir to a turbine. The strength, durability, and capacity to withstand high pressure and water flow make steel pipes a preferred option. Additionally, their resistance to corrosion ensures their suitability for long-term usage in hydropower systems. Moreover, the ease of welding or joining steel pipes enables flexibility in system design and installation. In summary, steel pipes are a dependable and extensively utilized alternative for hydropower systems.

- Q: What are the different methods of inspecting steel pipes?

- There are several methods of inspecting steel pipes, including visual inspection, non-destructive testing (such as ultrasonic testing, magnetic particle testing, and dye penetrant testing), radiographic testing, and eddy current testing. These methods help identify any defects, such as cracks, corrosion, or wall thickness variations, ensuring the quality and integrity of the steel pipes.

- Q: What is the difference between steel pipes and concrete pipes?

- The main difference between steel pipes and concrete pipes lies in their composition and physical properties. Steel pipes are made from a combination of iron and carbon, which makes them strong, durable, and resistant to corrosion. Concrete pipes, on the other hand, are made from a mixture of cement, sand, and aggregates, giving them a solid structure and high compressive strength. In terms of installation, steel pipes are typically lighter and easier to handle, making them more convenient for transportation and installation. Concrete pipes, due to their weight and bulkiness, require heavy machinery or specialized equipment for handling and placement. Additionally, steel pipes have a smooth interior surface, which allows for efficient fluid flow and minimizes friction. Concrete pipes, on the contrary, have a rougher interior surface that can cause friction and impede the flow of fluids. When it comes to cost, steel pipes tend to be more expensive than concrete pipes, primarily due to the higher cost of raw materials and manufacturing processes involved. Both steel and concrete pipes have their specific applications and advantages. Steel pipes are commonly used in industries such as oil and gas, water supply, and construction, where strength and durability are crucial. Concrete pipes are often used in sewer systems, stormwater drainage, and culverts, where their high load-bearing capacity and resistance to chemical erosion make them suitable options.

- Q: Can steel pipes be used for underground oil and gas pipelines?

- Yes, steel pipes can be used for underground oil and gas pipelines. Steel is a commonly used material for such pipelines due to its strength, durability, and ability to withstand high pressure and extreme temperatures. Additionally, steel pipes can be coated or lined with corrosion-resistant materials to protect them from the corrosive properties of oil and gas.

- Q: How do you protect steel pipes from external damage?

- One way to protect steel pipes from external damage is by applying a protective coating or paint. This can help prevent corrosion and other forms of physical damage caused by exposure to moisture, chemicals, or rough surfaces. Additionally, using pipe supports and installing guards or barriers can help shield the pipes from potential impact or accidental damage. Regular inspections and maintenance are also crucial to identify and address any signs of damage or wear in a timely manner.

- Q: What are the factors to consider when selecting pipe materials for corrosive environments?

- When selecting pipe materials for corrosive environments, there are several factors to consider. Firstly, the chemical composition and concentration of the corrosive substances must be evaluated, as different materials have varying resistance to specific chemicals. The temperature and pressure conditions in the environment also play a crucial role in material selection, as some materials may degrade or become brittle under extreme conditions. Additionally, the pipe's mechanical properties, such as strength and flexibility, should be assessed to ensure it can withstand the corrosive environment. The cost and availability of the chosen material, as well as its compatibility with other components in the system, should also be taken into account. Overall, a comprehensive understanding of the corrosive environment and thorough research on material properties are essential for selecting the most suitable pipe material.

- Q: Can steel pipes be used for bridge construction?

- Yes, steel pipes can be used for bridge construction. Steel pipes are commonly used in bridge construction due to their high strength, durability, and ability to withstand heavy loads. They offer excellent structural support, making them suitable for various bridge components such as piers, columns, and beams. Additionally, steel pipes can be easily fabricated, transported, and assembled, making them a popular choice in the construction industry.

- Q: What are low-pressure carbon steel tubes?

- Pipe fittingsA pipe fitting is a piece of pipe that is connected to a pipe. According to the connection method can be divided into socket type pipe fittings, threaded fittings, flange fittings and welding pipe four categories. Multipurpose; made of the same material as pipes. Elbow (elbow), flange, three pipe and four pipe (crosshead) and reducer (reducer) etc.. Elbow for pipeline corner; flange for the pipe and pipe interconnected parts, connected to the pipe end, three pipe for three pipe collection; four pipe for four tubes together place; for two pipes of different diameters connected to different diameter pipe.

- Q: What is the difference between steel pipes and polyethylene pipes?

- Steel pipes and polyethylene pipes are two types of piping materials that have different characteristics and uses. Steel pipes are made of a durable and strong material, making them suitable for high-pressure applications and transporting fluids or gases. They have a high resistance to heat, corrosion, and impacts, making them ideal for industrial and heavy-duty applications. Steel pipes are commonly used in industries such as oil and gas, construction, and infrastructure projects. Polyethylene pipes, on the other hand, are made of a flexible and lightweight plastic material known as polyethylene. They are commonly used for underground water supply systems, irrigation, and drainage systems. Polyethylene pipes have excellent resistance to chemicals, making them suitable for transporting water and other fluids. They are also more affordable and easier to install compared to steel pipes. In summary, the main difference between steel pipes and polyethylene pipes lies in their material composition, strength, and applications. Steel pipes are stronger and suitable for high-pressure applications, while polyethylene pipes are flexible, lightweight, and commonly used for water supply and drainage systems.

1. Manufacturer Overview

| Location | Shanghai China |

| Year Established | 1999 |

| Annual Output Value | Above Thirty Million RMB |

| Main Markets | Main land;Middle East; Southeast Asia |

| Company Certifications | ISO 9001:2010;API 5L |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Baoshan |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 300-500 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 30,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

API 5CT Oil Tubing and Tubing Pipe Seamless and Erw

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1t m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords