API 5CT H40 casing pipe for water well

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

API 5CT H40 Quality Standard

SY/T 6194 -------------Petroleum and natural gas industries Steel pipes for use as casing or tubing for wells

API 5CT----------------CASING AND TUBING

BS EN ISO 11960 ---Petroleum and natural gas industries Steel pipes for use as casing or tubing for wells

NF M87-207 ----------Petroleum and natural gas industries Steel pipes for use as casing or tubing for wells

JIS G3439 ------------SEAMLESS STEEL OIL WELL CASING, TUBING AND DRILL PIPE

IS 4270 ----------------Steel tubes for well spainend casing pipes

API 5CT H40 casing pipe for water well

Our company produces H40 casing pipe strictly according to the API 5 CT standards.Dalipal Company is one of the most famous enterprises of china professionally producing pipeline and oil casing.We can supply API 5CT series of pipeline and oil casing with all kinds of specifications and materials.We have first-class production equipment and technology.

Main Specification

Grade | API 5CT H40 Casing Pipe for water well |

External thickness | “4 1/2- 20”inch, (114.30- 508.00 mm) |

Wall thickness | 5.21-16.13 mm |

Thread form | BC(buttress casing),LC( long casing),SC( short casing) |

Function | used for protecting pipeline |

Length:

R1-(6.10m~7.32m),R2-(7.62/8.53)~10.36m,R3-(10.36/10.97~14.63m)

Certificate:

API 5CT,Russian Certificate,ISO,CCS

Packing:

Coating and steel thread protector

Usage:

Casing pipes are used for oil , gas and water wells. Steel casing pipes and tubing are applied to furnishing and installing cased tunnels, where they indicate to pass other utilities or obstructions without open excavation. Steel casing pipes and tube have smooth wall and a minimum yield strength of 35,000 psi. Corrosion-proofing water-based paint is applied on the outside pipe surface to protect against atmospheric corrosion during transportation and storage. The pipes can be delivered with metal or composite caps at both ends for thread protection.Casing pipes are manufactured out of steel are smelted in the electric furnace, treated with synthetic slags and cast by continuous casters. The applied steel making process ensures the achievement of chemically pure steel with reference to sulphur and phosphor contents providing high tensile, ductility and corrosion resistance properties of pipes to be operated at low temperatures in various corrosion media. Pipes are heat-treated in a computerized walking beam furnace. Steel grades and heat treatment regimes applied allow high-strength pipe to be obtained.

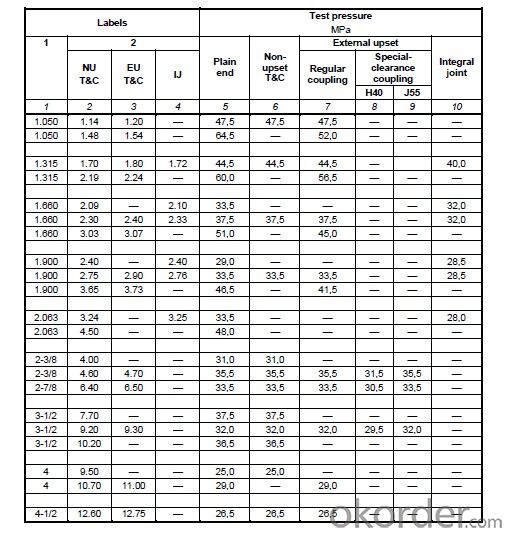

API Specification 5CT / ISO 11960

Hydrostatic test pressure for Grade H40 tubing

We have the ability to detect the whole process. We can fully guarantee the high quality of the products.

80t electric arc furnace smelting→ LF refining → VD vacuum degassing treatment→4 machine 4 strand machine →slow cooling pit slow cooling → rolling →fine grinding → straightening → heat treatment→ machining →inspection→packaging → warehousing.

Dalipal Company is one of the most famous enterprises of china professionally producing pipeline and oil casing.We can supply API 5CT series of pipeline and oil casing with all kinds of specifications and materials.We have first-class production equipment and technology.

- Q: How do steel pipes handle ground settlement?

- One possible alternative: Due to their robustness and durability, steel pipes are highly suitable for managing ground settlement. The pipes' flexibility and strength enable them to endure the shifting and settling of the ground with minimal damage. Their high resistance to deformation ensures that they can maintain their shape and structural integrity even when the ground settles or moves. When the ground settles, steel pipes can flex and bend slightly to accommodate the movement. This flexibility allows them to adapt to changes in the ground without experiencing breakage or cracking. Additionally, steel pipes often incorporate joints designed to absorb and distribute stress caused by ground settlement. Moreover, steel pipes possess a smooth interior surface that reduces friction and resistance to material flow. This characteristic becomes particularly crucial when the ground settles, as it diminishes the chances of blockages or clogs due to debris or sediment settling inside the pipes. In conclusion, steel pipes possess the necessary strength, flexibility, and resistance to deformation to effectively handle ground settlement. They can adapt to ground movement without compromising their structural integrity, making them a dependable choice for various applications such as underground infrastructure and pipeline systems.

- Q: How do steel pipes compare to other materials in terms of cost?

- Steel pipes are generally more cost-effective than many other materials used for pipes, thanks to their durability, strength, and availability. While initial costs may vary depending on factors like size and grade, steel pipes offer a longer lifespan and require less maintenance compared to other materials, making them a cost-efficient choice in the long run.

- Q: What is the typical diameter range for steel pipes?

- The typical diameter range for steel pipes varies, but it typically falls between 1/2 inch to 48 inches.

- Q: What are the common applications of steel pipes in the oil and gas industry?

- Steel pipes are commonly used in the oil and gas industry for various applications such as drilling, transportation of crude oil and natural gas, and for constructing pipelines and storage tanks. They provide strength, durability, and resistance to corrosion, making them ideal for these critical operations.

- Q: What are the different methods of pressure testing steel pipes?

- There are several methods of pressure testing steel pipes, including hydrostatic testing, pneumatic testing, and ultrasonic testing. Hydrostatic testing involves filling the pipe with water and applying pressure to check for leaks or weaknesses. Pneumatic testing uses compressed air or gas to pressurize the pipe and detect any leaks or failures. Ultrasonic testing utilizes high-frequency sound waves to inspect the pipe's integrity by detecting any flaws or defects.

- Q: How are steel pipes used in the manufacturing of chemical storage tanks?

- Steel pipes are commonly used in the manufacturing of chemical storage tanks as they provide structural support and serve as conduits for the transportation of chemicals. These pipes are typically used for connecting various components of the tank, such as the inlet and outlet valves, as well as for creating the internal plumbing system. The durability and corrosion resistance of steel make it an ideal material for ensuring the integrity and longevity of chemical storage tanks.

- Q: How are steel pipes used in the manufacturing of chemical processing plants?

- Steel pipes are commonly used in chemical processing plants for various purposes, such as transporting fluids and gases, as well as providing structural support. They are highly resistant to corrosion, making them ideal for handling corrosive materials in the plant. Additionally, steel pipes can withstand high temperatures and pressure, ensuring the safe and efficient operation of chemical processes.

- Q: What are the different methods of insulation for steel pipes?

- There are several methods of insulating steel pipes, including applying a thermal insulation coating, using pipe wraps or jackets, using foam insulation, or utilizing heat shrink sleeves.

- Q: Are steel pipes suitable for chemical processing plants?

- Yes, steel pipes are suitable for chemical processing plants. Steel pipes have excellent strength and durability, making them resistant to corrosion and able to withstand high pressure and temperature conditions common in chemical processing plants. Additionally, steel pipes can be easily welded, offering flexibility in design and installation.

- Q: What are the different types of supports used for underground steel pipes?

- The different types of supports used for underground steel pipes include concrete encasement, pipe bedding, pipe cradles, and pipe hangers. Concrete encasement involves surrounding the pipe with a layer of concrete to provide additional strength and stability. Pipe bedding involves placing a layer of granular material underneath the pipe to distribute the load and prevent excessive deflection. Pipe cradles are structures that support the pipe from underneath, typically made of concrete or steel. Pipe hangers are used to suspend the pipe from above, typically attached to a structure or support system. These supports help ensure the stability and longevity of underground steel pipes.

Send your message to us

API 5CT H40 casing pipe for water well

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords