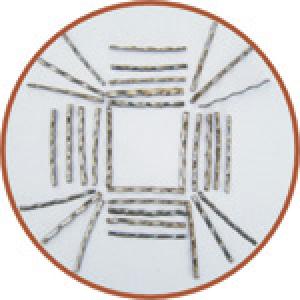

Anchoring nails

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CNBM is the leading supplier of refractory anchors. We have been serving the industry's refractory needs for over 30 years.

Refractory metal is available in hex steel grid, special grid and expanded metal. All material is available in stainless steel and grades T304, T316, T310, T330 as well as all of the standard grades. Other refractory insulation and refractory lining products include wire mesh, expanded metal mesh and hex steel grid.

Refractory anchors and related materials are used for anchoring and assembling refractory ceramic fibre linings or for reinforcing monolithic linings of castables, plastics or ramming mixes. We carry a complete selection of refractory anchors. We can supply you with refractory anchors to suit any depth of lining. Our refractory anchor selection includes studs, V-clips, C-clips, and miscellaneous parts.

- Q: What are the challenges and innovations in the steel product manufacturing industry?

- The steel product manufacturing industry faces several challenges, including fluctuating raw material costs, intense global competition, and increased environmental regulations. These challenges have led to the need for innovative solutions in order to remain competitive and sustainable. Some of the key innovations in the industry include the adoption of advanced technologies like automation and robotics, the development of high-performance alloys and coatings, and the implementation of energy-efficient processes. Additionally, the industry is exploring new business models, such as circular economy principles, to minimize waste and maximize resource utilization. Overall, the challenges in the steel product manufacturing industry have spurred the industry to embrace innovative practices that enhance productivity, reduce costs, and mitigate environmental impacts.

- Q: What are the different types of steel alloys?

- There are several different types of steel alloys, including carbon steel, stainless steel, tool steel, alloy steel, and high-strength low-alloy steel.

- Q: How can steel products be recycled and reused?

- Steel products can be recycled and reused through a process called steel recycling. This involves collecting and sorting steel materials, such as scrap metal, from various sources. The collected steel is then melted down in a furnace and transformed into new steel products. This recycling process not only conserves natural resources but also reduces the energy and emissions associated with steel production. Additionally, steel products can be reused by refurbishing or repurposing them for different applications, extending their lifespan and minimizing waste.

- Q: What are the common uses of steel in the aerospace industry?

- Steel is commonly used in the aerospace industry for a variety of applications, including structural components, engine parts, landing gear, and fasteners. Its high strength-to-weight ratio, durability, and resistance to extreme temperatures make it ideal for these critical and demanding aerospace applications.

- Q: What are the different types of steel wire and cables available?

- There are several types of steel wire and cables available, including galvanized steel wire, stainless steel wire, carbon steel wire, and alloy steel wire. Each type has its own unique properties and characteristics, making them suitable for various applications such as construction, automotive, electrical, and telecommunications.

- Q: How is steel used in the manufacturing of water treatment systems?

- Steel is commonly used in the manufacturing of water treatment systems due to its durability and corrosion resistance. It is used to construct various components of these systems such as tanks, pipes, and frames. Steel ensures the structural integrity of the system and helps in withstanding the harsh conditions often found in water treatment processes.

- Q: What are the advantages of using steel products over other materials?

- There are several advantages of using steel products over other materials. Firstly, steel is known for its exceptional strength and durability, making it highly resistant to wear, tear, and extreme weather conditions. Secondly, steel products have a longer lifespan compared to other materials, reducing the need for frequent replacements. Additionally, steel is a versatile material that can be easily molded and shaped to meet specific design requirements. Moreover, steel is recyclable, making it an environmentally friendly choice. Lastly, steel offers excellent fire resistance, making it a safer option in various applications.

- Q: What are the different types of steel profiles and their applications?

- There are various types of steel profiles used in different applications. Some common types include I-beams, H-beams, angles, channels, and T-sections. I-beams are often used in structural construction due to their high strength and load-bearing capacity. H-beams are similar to I-beams but have wider flanges, making them suitable for heavier loads. Angles are commonly used for framing and support, while channels are utilized in construction and manufacturing. T-sections are commonly used for structural purposes and can provide stability in various applications.

- Q: What are the different types of steel angles and their applications in construction?

- There are several different types of steel angles used in construction, including equal angles, unequal angles, and L-shaped angles. Equal angles have equal sides and are commonly used as structural components to provide support and stability. Unequal angles have different length sides and are often used to create transitions or to accommodate specific design requirements. L-shaped angles, also known as corner or bracket angles, are used to reinforce corners and joints in construction projects. Overall, steel angles are versatile and essential components in construction, providing strength and stability to various structures and applications.

- Q: What are the different types of steel valves and their applications?

- There are several types of steel valves commonly used in various industries. These include gate valves, globe valves, ball valves, butterfly valves, and check valves. Gate valves are primarily used for on/off applications and provide a tight seal when closed. They are commonly used in water treatment plants, oil and gas pipelines, and power generation systems. Globe valves have a spherical body and are suitable for regulating flow. They are frequently used in industries such as HVAC, steam systems, and chemical processing. Ball valves consist of a rotating ball with a hole that controls flow. They are versatile and widely used in applications where tight shut-off is required, such as oil and gas pipelines, chemical plants, and water treatment systems. Butterfly valves have a disc-shaped closure element that rotates to control flow. They are lightweight, cost-effective, and commonly used in applications involving large flow rates, such as HVAC systems, water supply networks, and wastewater treatment plants. Check valves, also known as non-return valves, allow flow in one direction only and prevent backflow. They are used in various applications, including pumps, compressors, and power plants. Each type of steel valve serves specific purposes based on their design and functionality. The choice of valve depends on factors such as the nature of the fluid, pressure and temperature requirements, and the specific application in industries ranging from oil and gas to water treatment and beyond.

Send your message to us

Anchoring nails

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords