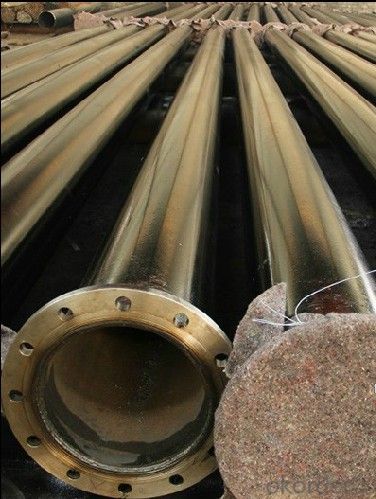

American Standard Pipe Ends Weld Flange Connections

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25-35 m.t.

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Material: | Carbon Steel | Technics: | Forged | Type: | Union |

| Place of Origin: | China (Mainland) | Model Number: | DN25-DN1000 | ||

| Connection: | Flange | Shape: | Equal | Head Code: | round |

Packaging & Delivery

| Packaging Detail: | standard seaworthy package ,or air transportation package |

| Delivery Detail: | According to ordered quantity and the requirement from Customer |

Specifications

Design expansion joints

Cycle life: 5000 times

Large size available

EJMA code bellows

JIS ANSI DIN BS JB flange

Date:

| Size available | DN25 till DN1000 |

| Material | sus304, 321, 316L... |

| Application temperature | -50 ~ 300 °C |

| Pressure | 0.25MPa - 120MPa |

| Cycle life | 5000 times |

| Structure | bellows, flange, pipe end, internal sleeve, tie-rod, nut |

| Connection type | flange, welded |

| Flange and pipe end | stainless steel, carbon steel |

Features:

Absorb axial & radial & angle displacement.

Absorb Expansion and Contraction of temperature cause.

Resolve minor deviation, eliminate pipeline residual stress.

Reduce mounting bracket & improve economic performance.

Easy cleaning and maintenance.

Used for chemical / metallurgy / electricity / shipbuilding / construction and other industries.

Pipe Ends Weld Flange Connections Image

FAQ of Pipe Ends Weld Flange Connections

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard.Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

Any question, pls feel free to contact us !

- Q: What does "steel pipe SC" mean?

- SC (run in welded steel duitconSC is the line laying mode GB letter of wire is worn steel pipe laying (welded steel pipe, low pressure fluid) SC70 said the conductor by low pressure fluid DN70 welded steel pipe as protection pipe laying, DN70 said the nominal pipe diameter is 70mm, the nominal pipe diameter is 70mm (a series of values, the actual diameter slightly different).

- Q: Can steel pipes be used for underground fire sprinkler systems?

- Yes, steel pipes can be used for underground fire sprinkler systems. Steel pipes are commonly used in fire sprinkler systems due to their strength, durability, and resistance to heat and corrosion. They are suitable for underground installations as they provide reliable and long-lasting performance. Additionally, steel pipes are available in various sizes and configurations, allowing for flexibility in designing and installing underground fire sprinkler systems. However, it is important to ensure that the steel pipes are properly coated or protected to prevent corrosion and ensure their effectiveness in an underground environment. Regular inspections and maintenance are also necessary to detect any potential issues or damages to the steel pipes in order to maintain the safety and functionality of the fire sprinkler system.

- Q: How do steel pipes handle pressure surges?

- Steel pipes are designed to handle pressure surges effectively due to their inherent strength and durability. The high tensile strength of steel allows it to withstand significant pressure fluctuations without deforming or bursting. Additionally, the seamless construction of steel pipes ensures a smooth and continuous flow, minimizing the impact of pressure surges. Furthermore, steel pipes can be reinforced with additional support structures, such as braces or anchors, to further enhance their ability to handle pressure surges.

- Q: Are steel pipes magnetic?

- It is true that steel pipes have the ability to become magnetic. Steel, mainly composed of iron, possesses ferromagnetic properties. Consequently, it can be magnetized or drawn towards magnets. Nevertheless, it is important to note that not all steel pipes are magnetic due to the variability in steel's magnetic characteristics, which depend on the specific composition and production methods employed. By incorporating specific alloying elements or subjecting it to particular heat treatments, steel can be rendered non-magnetic in certain instances. Moreover, the strength of the magnetic field exhibited by steel pipes varies based on factors such as pipe thickness and the magnet's intensity.

- Q: What is galvanized steel pipe?

- Galvanized steel pipe is a type of steel pipe that has been coated with a layer of zinc, which helps protect it from corrosion and rust. This coating also increases the pipe's longevity and makes it suitable for various applications, including plumbing, construction, and outdoor structures.

- Q: What is the difference between steel pipes and concrete-lined pipes?

- The main difference between steel pipes and concrete-lined pipes lies in their composition and protective features. Steel pipes are typically made entirely of steel, providing strength and durability. On the other hand, concrete-lined pipes consist of a steel pipe coated with a layer of concrete. This lining offers additional protection against corrosion and abrasion. While steel pipes are more suitable for high-pressure applications and offer better resistance to external factors, concrete-lined pipes are commonly used in wastewater systems to prevent corrosion and extend the lifespan of the pipe.

- Q: What is the fire rating of steel pipes?

- The fire rating of steel pipes can vary depending on factors such as the thickness of the pipe, the type of insulation or fireproofing materials used, and the specific application or building codes. However, steel pipes are generally considered to have good fire resistance properties due to their non-combustible nature and ability to withstand high temperatures.

- Q: How do steel pipes handle chemical substances?

- Steel pipes are highly resistant to chemical substances due to their high strength and corrosion-resistant properties. They can safely handle a wide range of chemical substances without undergoing any significant degradation or damage.

- Q: How are steel pipes protected against rust?

- Steel pipes are protected against rust through various methods such as galvanization, epoxy coating, and using corrosion-resistant alloys.

- Q: What is the difference between steel pipes and polyethylene pipes?

- Steel pipes are made of a strong and durable material, steel, which makes them suitable for high-pressure and high-temperature applications. They are also resistant to corrosion, making them ideal for transporting liquids and gases. On the other hand, polyethylene pipes are made of a flexible plastic material, which makes them easier to install and handle. They are lightweight, resistant to chemicals, and have a low risk of corrosion. However, they may not be suitable for very high-pressure or high-temperature applications.

Send your message to us

American Standard Pipe Ends Weld Flange Connections

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25-35 m.t.

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords