Aluminum Foil Facing Mylar for Bubble Heat Seal Composite Film

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 kg/m³

- Supply Capability:

- 500000 kg/m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Aluminum Foil Facing Description:

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

• FSK aluminum foil facing is mainly used for duct wrap in HVAC system and other fields, such as vapor barrier etc., and suitable for off-line lamination of glass wool or rock wool. By special processing, the facing will have excellent flame retardant property.

• Heat-sealing aluminum foil facing is used for duct wrap without applying extra adhesive and suitable for online lamination of glass wool and rock wool.

• The WPSK aluminum foil facing, whose structure is white polypropylene/ fiberglass scrim/ kraft is mainly used for metal building insulation and suitable for the insulation of ware-house, factory, supermarket, office and so on.

• Double sided aluminum foil facing vapor barrier, whose structure is aluminum foil/ high strength kraft /fiberglass scrim /aluminum foil and laminated together by special flame retardant adhesive, can be used for roofing, wall insulation of house, warehouse, cold storages, factory and others.

2.Main Features of the Aluminum foil facing:

• Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly,no smell and not-toxic;

• Smooth and clear surface;

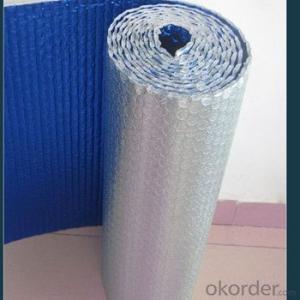

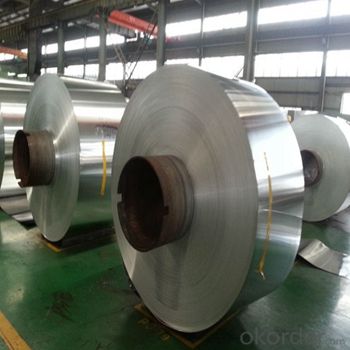

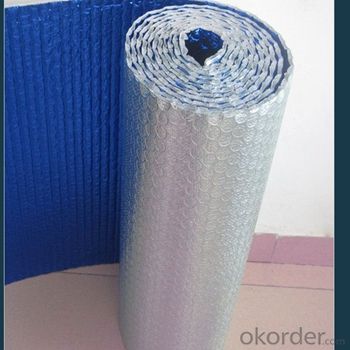

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 80 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 95 50 | ASTM C1136 |

Burst strength | N | 25 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C +66°C | No change keep soft | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Water Soak Test | 24hrs | No delamination | ---------- |

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.37m

Length: 200m, 500m, 1000m, 2500m, 2750m, 3300m

Core I.D.: 3"(76mm ±1), 72mm ±1

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

(1) How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

(2)What is the storage condition?

The products should be stored at room temperature and kept from wet and heat source.

It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

- Q: The lampblack machine to buy. There has been no tear the film. That is similar to the white plastic, very thin], now again tear is not very easy, but just like glue, stick to the appliance with a blade surface, if the like will leave traces, have what chemical method? Or is a shortcut?

- Special cleaning agent for cleaning air conditioning (such as "off", air conditioning has too much oil cooling effect on the use of this, the effect is very good), refrigeration accessories shop sell.

- Q: If I have known about the thickness, length and the diameter of the core of a roll of protective film, how can you know the diameter of the roll of film?

- The length equals 3.14 times the sum of the diameter of the whole roll and the diameter of the core. Or the length equals 2 times the difference between the diameter of the whole roll and the diameter of the core.

- Q: How about the electrostatic adsorptive function of PE protective film ?

- 1. Corona treatment is used in the process of the making of PE protective film, increasing the surface area of the film and making it static to meet the need of the following gluing. It's conducive to the combination of glue and film this way. 2. There's no such PE anti-static protective film with glue itself has adsorption function. Multi-layer film blowing machine can make such product at one time.

- Q: There are two screens in the computer screen. One side says "A", and the other is "B". Do you need to paste A first and then paste B? Do you have two at a time? Thank you

- You can see the following steps.1. will be marked with a membrane facing the quasi screen, and will be removed from the layer of film labels pulled, and slowly tear the part of the layer, please pay attention to fingers do not touch the protective film adsorption layer (middle layer)

- Q: How to remove the protective film on the door in a quick way?

- Tear it off quickly.

- Q: How to clean the keyboard protection film?How to wash the best?

- With a soft brush with detergent brush OK, dry food!

- Q: How to remove the protective film on stainless steel?

- Not to tear it down. Peel it off after it's heated by air heater and then wipe the surface of the stainless steel with a warm towel.

- Q: How to tear off the protective film on the stainless steel security door?

- The reason why you can't remove the film is that the outer film made from polyethylene material chemecally reacts with the surface paint of the door. And the film and the paint stick to each other. You can clean the film with some of the paint using thinners. But I think it doesn't affect too much.

- Q: Use of protective films,A lot of products can be posted ah,

- Introduction to protective film applications:The protective film according to the scope of application, can be used in the following areas: the surface of metal products, metal products, plastic products surface coating surface, automotive products surface, the surface of the electronic product, product surface, the surface profile of the product label, and other products surface.

- Q: What's the difference between the original film and the protective film?

- Fourth: to prevent electromagnetic radiation (film has a certain anti electromagnetic breaking effect), pregnant women and babies born as little as possible contact with radiation of electronic productsFifth: mirror the function of girls favorite (mirror film can be used as a mirror, to attend any place, you can use the phone as a mirror make-up)Sixth: variety of color film to highlight personalitySeventh: diamond film dazzlingEighth: the screen through regular film protection, not only mobile phone screen from scratch, oil contamination, and can reduce the use of mobile phone owners eye fatigue. There are more and more people who like to put their cell phones in their pockets, and most people have the problem that they have mobile phones, keyboards and screens which are easy to get into the dust

Send your message to us

Aluminum Foil Facing Mylar for Bubble Heat Seal Composite Film

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 kg/m³

- Supply Capability:

- 500000 kg/m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords