Aluminum Foil Facing Mylar for Bubble Heat Seal

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 kg/m³

- Supply Capability:

- 500000 kg/m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Aluminum Foil Facing Description:

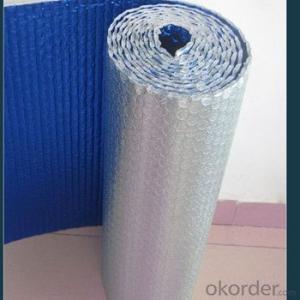

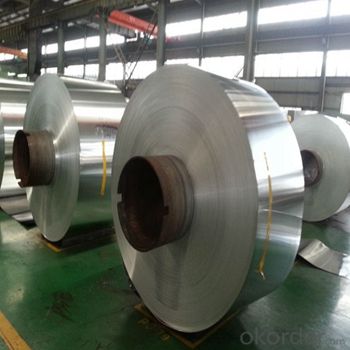

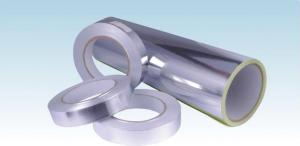

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

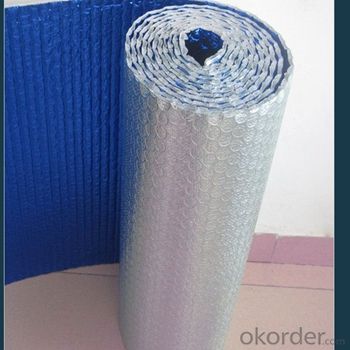

• FSK aluminum foil facing is mainly used for duct wrap in HVAC system and other fields, such as vapor barrier etc., and suitable for off-line lamination of glass wool or rock wool. By special processing, the facing will have excellent flame retardant property.

• Heat-sealing aluminum foil facing is used for duct wrap without applying extra adhesive and suitable for online lamination of glass wool and rock wool.

2.Main Features of the Aluminum foil facing:

• Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 80 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 95 50 | ASTM C1136 |

Burst strength | N | 25 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C +66°C | No change keep soft | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Water Soak Test | 24hrs | No delamination | ---------- |

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.37m

Length: 200m, 500m, 1000m, 2500m, 2750m, 3300m

Core I.D.: 3"(76mm ±1), 72mm ±1

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

(1) How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

(2)What is the storage condition?

The products should be stored at room temperature and kept from wet and heat source.

It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

- Q: What to do if the protective film on aluminium alloy is very difficult to remove?

- Heat it with electric hair dryer blowing and tear it at the same time. It will be easy to remove this way.

- Q: How to easily remove the protective films on ceramic tiles?

- There are three types of protective film used on ceramic tiles: The first one is plastic thin film which can be slowly torn by hands or gently rubbed off with steel wool; The second is anti-fouling protective film which can be wipe off using towel with white cement; The third is wax protective film which can be wipe off with dry towel with electric diluent, lacquer thinner, talcum powder or white cement.

- Q: The color of the aluminium-plastic panel is white without protective film. But I've seen other colors that looks like it's painted.

- This shows that the quality of the coating of the aluminium-plastic panel you bought is not good. The paint on the surface of the panel should be very even and consistent. There shouldn't be any dark stripe or marks or shades of the same color which usually appear in spraying processing.

- Q: What kind of printing press is needed to cover decorative protective film?

- During the processing of protective film, film mulching machine must be used in film mulching. And gravure rotary press can be used in printing the protective film.

- Q: There are two screens in the computer screen. One side says "A", and the other is "B". Do you need to paste A first and then paste B? Do you have two at a time? Thank you

- 2. the adsorption layer at the screen corner, make sure the position of alignment, while tearing, back from the film layer on the side of caution to heal, because now the protective film has automatic electrostatic adsorption function, do not need too much wait. The film moves slowly, along the long edge of the screen that a surface, from point to line, from line to surface in order to start.

- Q: Mobile phone protection film paste, and then ripped off, but also paste it? How should I post it?

- Methods / steps1 first package with a small cloth to clean the dust on the surface of the screen, wipe when, in order to from side to side do not wipe, wipe back and forth; note: first removed a small cloth on the small grain or lint cloth and then wipe.2, the general screen has three layers of film, choose the right size of the film, remove the bottom layer, (really useful is the middle layer), and then stick to the mobile phone screen, carefully stick down.

- Q: Composite wood floors above a transparent protective film began to fall off, what should I do?

- At the edge of the first open a small mouth, and then slowly from the edge along the diagonal direction.

- Q: What are the screens for mobile phones, PE, PET, PC, PVC, PMMA, or other plastic?

- PVC material itself is soft and paste easy, but this material is thick, light transmittance is not good, so that the screen looks more obscure. It also leaves a mark of glue on the screen. This material is also relatively easy to change with temperature and turn yellow oil, short service life.PET material is the most common kind of protective film material on the market at present. The texture is relatively hard, and it is more scratch resistant.

- Q: How to buy computer screen protection film?

- On the issue of "", help assistant to answer your kuba. For the purchase of computer screen protective film: first, buy LCD screen protective film should note: 1, absolutely free of glue on the market at present -- computer screen protective film product sales are mostly made of imitation Japanese material, the lack of PET synthesis technology, only the use of glue and PET combined with silicon. When the user's digital products are used, the heat generated by the glue will change at the temperature, resulting in some silicone began to fall off on the LCD screen, it is difficult to clean again, resulting in damage to the LCD screen.

- Q: Do you know if there is a computer screen that can be seen only from the front?

- I know what kind of film you're talking about! You're talking about an anti peeping film!!! The price is not very cheap!! The retail price is above 150!!! The film is attached to the computer and cannot be seen at a certain angle! But the transmittance is not very good!

Send your message to us

Aluminum Foil Facing Mylar for Bubble Heat Seal

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 kg/m³

- Supply Capability:

- 500000 kg/m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords