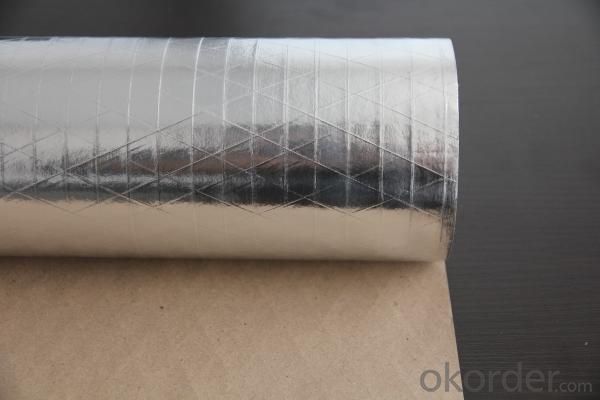

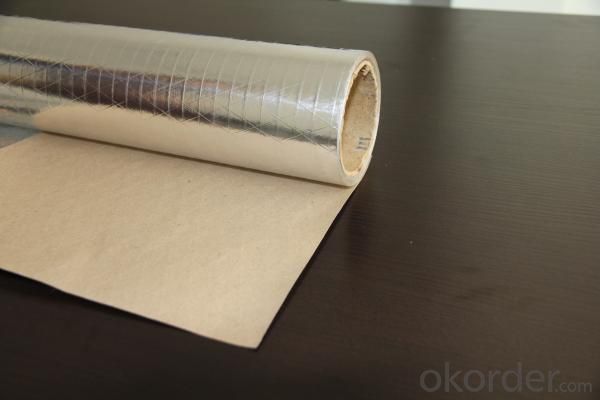

Aluminum Foil Facing FSK-R7160A

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000M2 m²

- Supply Capability:

- 20000M2 Per Day m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specifications of Aluminium Foil Facing; FSK-R7160A

Aluminum foil: 7 microns

Tri-way fiberglass scrim: M.D: 8/100mm; X.D: 12/100mm

Adhesive: Flame Retardant

Kraft paper: 60gsm (Natural)

TYPICAL PHYSICAL PROPERTIES:

|

PROPERTIES |

UNIT |

VALUE |

TEST METHOD |

|

Basic weight |

gsm |

98 |

ASTM D646 |

|

Tensile strength: M. D. X. D. |

N/25mm |

130 50 |

ASTM D828 |

|

Burst strength |

N |

30 |

ASTM D774 |

|

Reflectivity of foil surface |

% |

95 |

---------- |

|

Temp. Resistance |

-29°C 66°C |

No Delamination No Delamination |

ASTM C1263 |

|

Water vapor permeance |

ng/N.s |

5.75 |

ASTM E-96 |

|

Fire Rating |

Class |

B2 |

GB8624,GB/T8626 |

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.35m,1.37m

Length:300m, 500m, 1600m, 2750m, 3300m

Core I.D.:3"(76mm ±1)

Based on order, special sizes are also available.

Remarks:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm; Length: ±0.5%.

3. The products should be stored at room temperature, kept from wet and kept away heat source.

4.The users should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for their special purpose and technique.

2. Application of Aluminium Foil Facing; FSK-R7160A

FSK facing is mainly used for duct wrap in HVAC sustem and other fields, such as vapor barrier etc., and suitable for off-line lamination of glass wool or rock wool. By special processing, the facing will have excellent flame retardant property.

3. Packaging & Deliveryof Aluminium Foil Facing; FSK-R7160A

Depends on the clients' requirements and the production conditions.

- Q: This question asks for a comparison of the pros and cons associated with the use of aluminum foil facing in construction or other applications.

- <p>Aluminum foil facing has several advantages, including excellent heat and cold insulation properties, which can significantly improve energy efficiency. It is also lightweight, making it easy to handle and install. The material is resistant to corrosion and has a long lifespan, reducing maintenance and replacement costs. Additionally, it provides a smooth, clean surface that is easy to clean and maintain. However, there are disadvantages such as its high cost compared to some alternatives, which can be a barrier for some projects. It can also be damaged by sharp objects, which may compromise its integrity. Lastly, while it reflects heat, it can also reflect sound, potentially leading to acoustic issues in some environments.</p>

- Q: Is it safe and practical to use aluminum foil facing as a protective layer for a cutting board?

- <p>Yes, you can use aluminum foil facing as a temporary cover for a cutting board. It provides a smooth surface that can protect the cutting board from scratches and stains. However, it's not recommended for long-term use or heavy-duty cutting as it may tear or dent easily. For regular use, a proper cutting board cover or a plastic cutting mat is more durable and safer.</p>

- Q: What are the safety regulations or guidelines that aluminum foil facing must adhere to?

- <p>Safety standards for aluminum foil facing are crucial to ensure the product's safety and effectiveness. These standards typically include requirements for material composition, thickness, and bonding strength to ensure the foil's durability and resistance to tearing. Additionally, there are guidelines for the foil's reflectivity and heat resistance, which are important for its performance in various applications. Compliance with these standards is often verified through testing and certification processes, ensuring that aluminum foil facing products meet the necessary quality and safety benchmarks before they reach the market.</p>

- Q: How should aluminum foil be stored after it has been used for cooking or food storage to keep it clean and ready for future use?

- <p>The best ways to store aluminum foil facing after using it for cooking or food storage involve cleaning and organizing it properly. First, wash the used foil with warm soapy water to remove any food residue. Rinse it thoroughly and pat dry with a clean towel. To store, roll the foil tightly starting from the center, keeping it compact and neat. Alternatively, you can store it in a resealable plastic bag or a dedicated foil container to keep it clean and prevent it from tearing. Always store it in a cool, dry place away from direct sunlight to maintain its quality.</p>

- Q: Describe the process of aluminum foil facing in a few sentences.

- <p>Aluminum foil facing is a process used to laminate aluminum foil to a substrate, typically for decorative or functional purposes. The process begins with the preparation of the substrate, ensuring it is clean and free of contaminants. Then, a layer of adhesive is applied to the substrate. The aluminum foil is then placed onto the adhesive-covered substrate and pressure is applied to ensure proper adhesion. The laminated product is then cured, which can involve heat or UV light to set the adhesive. Finally, the product is trimmed and inspected for quality before being packaged and shipped. This process is used in various industries, including construction, automotive, and consumer goods.</p>

- Q: This question asks for the most effective methods to utilize aluminum foil when preparing food for freezing or frying, specifically focusing on the aluminum foil facing.

- <p>Aluminum foil facing is best used for preparing food for freezing or frying by ensuring even heat distribution and maintaining food's moisture. For freezing, line your baking sheet with aluminum foil facing down to prevent sticking and make removal easier. When freezing individual portions, wrap them tightly in foil to protect their shape. For frying, use foil to create a barrier between the food and direct heat, which can help in even cooking. Always make sure the foil is shiny side out for better heat reflection and椋熷搧瀹夊叏. Remember to avoid overheating as aluminum foil can melt at high temperatures.</p>

- Q: The user is asking if it's possible to use aluminum foil facing, which is a type of reflective material, for making desserts.

- <p>Yes, you can use aluminum foil facing in the process of making certain desserts, particularly for baking. It can help reflect heat in the oven, ensuring even cooking and browning. For example, when making meringues or pavlovas, aluminum foil can be used to catch any drips from the oven. However, it's not typically used as an ingredient in the dessert itself. Always ensure that the foil is food-safe and follows any specific recipe guidelines regarding its use.</p>

- Q: This question asks for methods to prevent metal flakes from aluminum foil from getting into the eyes or mouth while using it.

- <p>To avoid getting metal flakes from aluminum foil into your eyes or mouth, handle the foil carefully with clean, dry hands. Avoid using foil that is crumpled or damaged, as it can release more flakes. When cutting foil, use a sharp knife to minimize the creation of small particles. Keep foil away from your face and eyes while handling, and consider wearing safety glasses if you are concerned about eye safety. Wash your hands thoroughly after handling aluminum foil to remove any residual flakes before touching your face or eating.</p>

- Q: The user is asking if it's possible to use aluminum foil with a shiny side facing outward to create a sandwich roll.

- <p>Yes, you can use aluminum foil to make a sandwich roll, but it's not recommended to use the shiny side facing outward. The dull side of the foil is typically used for food contact because it's less likely to transfer any potential residues or chemicals to the food. The shiny side may have a coating that isn't safe for direct food contact. Always ensure that the foil is food-safe and use it according to the manufacturer's instructions.</p>

- Q: The user is asking if aluminum foil can be used as a replacement for tin foil in baking and grilling applications.

- <p>Yes, you can use aluminum foil as a substitute for tin foil in baking pans or grilling pans. Both aluminum and tin foil are commonly used for similar purposes, such as lining pans, wrapping food, and preventing food from sticking. Aluminum foil is more widely available and less expensive than tin foil. It conducts heat well and is non-toxic, making it a suitable alternative for most baking and grilling needs. However, note that aluminum may react with acidic foods, so it's best to avoid using it in such cases or to use a heavier gauge to minimize contact with the food.</p>

1. Manufacturer Overview

| Location | Jangsu, China |

| Year Established | 1999 |

| Annual Output Value | Above US$ 0.3 billion |

| Main Markets | 0.00% Mid East 0.00% Northern Europe 15.00% North America 10.00% Eastern Asia 20.00% Africa 0.00% Eastern Europe 20.00% Southeast Asia 0.00% Oceania 0.00% Western Europe 0.00% Southern Europe South east asia;North America,South America |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 4 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum Foil Facing FSK-R7160A

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000M2 m²

- Supply Capability:

- 20000M2 Per Day m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords